When it comes to your engine’s performance, the cylinder head plays a critical role. It’s not just a piece of metal; it’s the heart of your engine’s combustion process. If you’re experiencing issues like overheating, poor fuel efficiency, or strange noises, it might be time to investigate potential cylinder head problems. Ignoring these signs could lead to costly repairs down the line.

Understanding the common issues associated with cylinder heads can save you both time and money. From cracks to warping, these problems can impact your vehicle’s overall performance and longevity. Don’t let a small issue turn into a major headache. By staying informed and proactive, you can keep your engine running smoothly and efficiently. Jump into the details and discover how to identify and address these cylinder head problems before they escalate.

Overview of Cylinder Head Problems

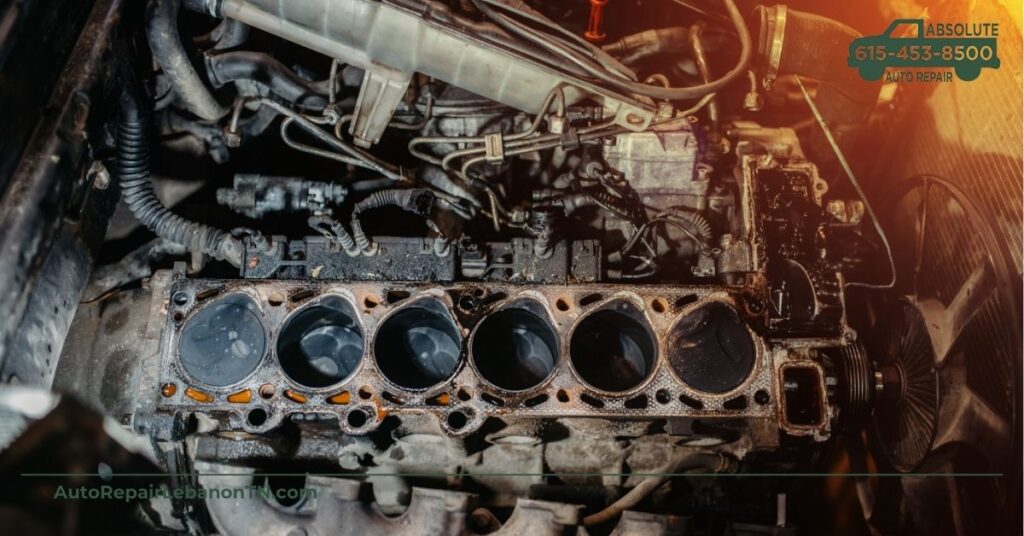

Cylinder head problems can significantly impact your engine’s performance. Common issues include cracks, warping, gasket failure, and valve-related problems. Overheating often leads to these failures, resulting in poor fuel efficiency and increased emissions. Unusual noises from the engine may signal underlying cylinder head problems, requiring your attention.

You should recognize that cracks in the cylinder head may allow coolant to leak into the combustion chamber. Warping occurs due to excessive heat or pressure, compromising the seal and leading to potential engine failure. Gasket failure between the cylinder head and engine block often results in coolant and oil mixing, creating severe operational issues.

Regular maintenance and inspections can help identify these issues early. Keeping an eye on engine temperature gauges and noticing changes in performance is essential. If you suspect problems, consult a qualified mechanic to assess and address the situation promptly. By being proactive, you can prevent minor cylinder head issues from escalating into major engine problems.

Common Symptoms of Cylinder Head Issues

You must pay attention to the symptoms of cylinder head problems as they can lead to severe engine issues. Overheating, oil leaks, and poor engine performance are key indicators to look for.

Overheating Engine

Overheating often signifies a cylinder head issue. This condition arises when the cylinder head warps or cracks, interrupting coolant flow. A low coolant level or coolant loss can contribute to this problem. Air pockets may also hinder proper cooling. Also, a malfunctioning thermostat may prevent correct temperature regulation, exacerbating overheating.

Oil Leaks

Oil leaks serve as another clear sign of cylinder head problems. A cracked cylinder head can lead to noticeable oil spots around the cylinder head area or trigger an oil light on your dashboard. Such leaks can decrease oil levels, increasing the risk of engine damage. If you observe oil in unexpected places, addressing the issue promptly is crucial.

Poor Engine Performance

Poor engine performance frequently accompanies cylinder head issues. Affected engines may exhibit sluggish acceleration or reduced power. Engine misfires can also occur if coolant enters the combustion chamber due to cracks. Remaining vigilant for changes in performance can help you catch cylinder head problems early.

Types of Cylinder Head Problems

Cylinder head issues can significantly affect engine performance. Understanding these problems helps you identify potential issues early.

Cracks and Leaks

Cracks and leaks are prevalent in cylinder heads and often stem from overheating. This common issue arises when the engine’s temperature exceeds safe limits, causing the cylinder head to expand and contract unevenly. Thermo-mechanical stress plays a role as well. Specifically, the valve bridge area becomes susceptible to fatigue due to repeated thermal loading and combustion pressure, leading to cracks. Engine designs that feature different materials, like a cast iron block paired with an aluminum head, face another challenge. These materials expand and contract at different rates, increasing the likelihood of cracks and leaks.

Warped Cylinder Heads

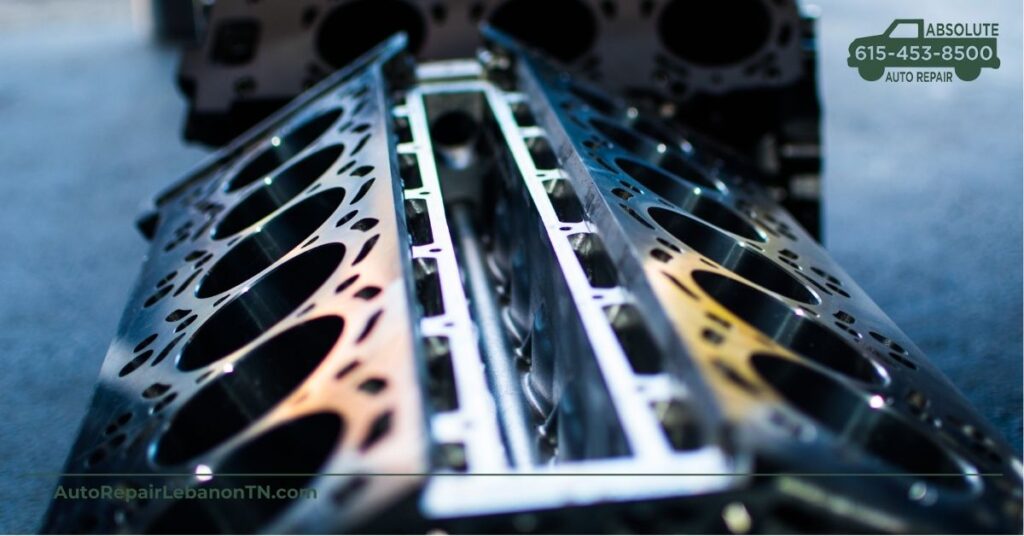

Warped cylinder heads can severely disrupt engine function. Excessive heat and pressure typically cause warping, which compromises the cylinder head’s seals. When warping occurs, the deformation hinders the proper flow of coolant. This can result in more overheating and subsequent damage if not addressed promptly. In terms of repairs, you might find resurfacing as a common solution. But, if the warping is important, replacements often become necessary to restore engine integrity.

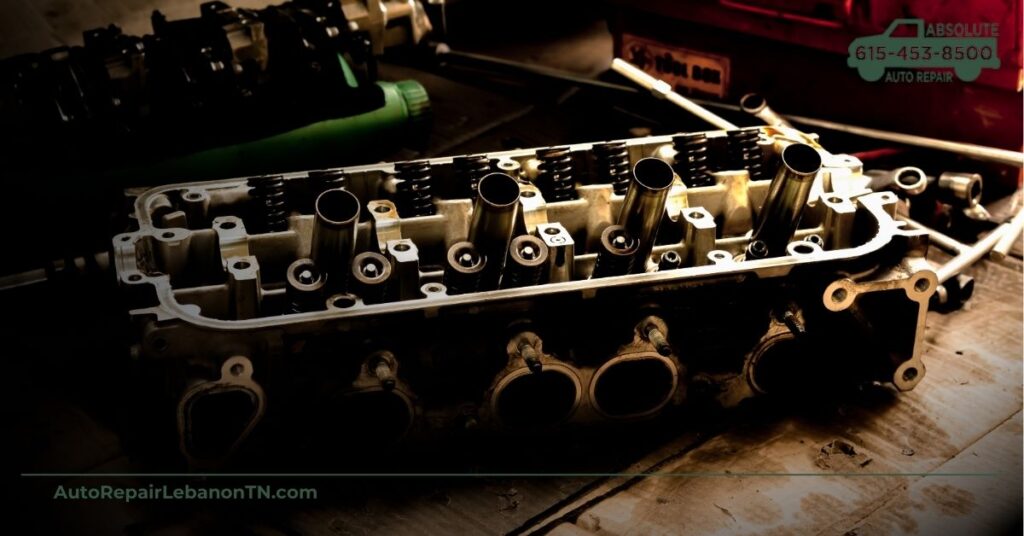

Valve Train Failures

Valve train failures can cause notable performance issues. The valve train system is crucial in regulating air and fuel intake as well as exhaust expulsion. Problems in this area may lead to misfires or reduced power. As components wear down, you might experience symptoms like unusual noises or decreased acceleration. Frequent inspections of the valve springs and rocker arms can help identify wear early. If left unresolved, these failures might lead to more important engine damage, necessitating costly repairs.

Diagnosing Cylinder Head Problems

Diagnosing cylinder head problems involves various techniques to accurately identify issues affecting engine performance. Common procedures provide insights into the condition of the cylinder head.

Visual Inspection Techniques

Start with a visual examination of the cylinder head. Look for cracks, warping, or coolant leaks. Check for signs of corrosion or unusual wear near the gasket area. Conduct this inspection during routine maintenance to catch problems early. If visible damage is present, it may indicate more important issues requiring further testing or repair.

Compression Testing

Compression testing offers another effective method for diagnosing cylinder head problems. Measure the compression levels in each cylinder using a compression gauge. Compare the readings across cylinders; important differences point to potential head issues. Low compression often suggests problems like cracks or warping that compromise sealing. Repeat the test after adding a small amount of oil to determine if the issue originates from the cylinder head or piston rings. Identifying these discrepancies early can prevent costly engine repairs later.

Repair and Maintenance Solutions

Cylinder head issues require timely and effective repair strategies. Addressing them promptly can maintain engine performance and longevity.

Professional Repairs

Turn to professional mechanics for complex cylinder head problems. They possess specialized tools and skills needed for thorough inspections and accurate diagnoses. Services may include resurfacing warped heads or replacing cracked ones. Experienced technicians can also handle valve train repairs and perform necessary maintenance checks. Relying on professionals ensures optimal repair and prevents future complications.

DIY Fixes

Consider simple DIY fixes for minor cylinder head concerns. Keep in mind that timely intervention is crucial. Replace faulty gaskets to prevent oil and coolant leaks. Check for visible damage during regular inspections, as this can prevent further issues. Monitor engine temperature to avoid overheating. If you’re comfortable with tools, you might perform coolant flushes to maintain optimal flow. Regular maintenance can also reduce wear on components, allowing your engine to run smoothly.

Conclusion

Staying vigilant about cylinder head problems is crucial for maintaining your engine’s health. By recognizing symptoms early and addressing issues promptly, you can prevent costly repairs and ensure optimal performance. Regular inspections and maintenance are your best allies in this try. Don’t hesitate to consult a qualified mechanic if you suspect any issues. Taking these proactive steps will help keep your engine running smoothly and efficiently for years to come.

Frequently Asked Questions

What is the role of the cylinder head in an engine?

The cylinder head is a crucial component that houses the combustion chamber and facilitates the flow of air and fuel. It plays a key role in engine performance by containing valves and spark plugs, influencing combustion efficiency.

What are common symptoms of cylinder head problems?

Common symptoms include overheating, oil leaks, and poor engine performance. Overheating often results from warping or cracking, while oil leaks may appear around the cylinder head. Poor performance can be characterized by sluggish acceleration or misfires.

How can I detect cylinder head issues early?

Early detection can be achieved through visual inspections for cracks or leaks during routine maintenance. Monitoring engine temperature gauges and conducting compression tests can also help identify issues before they escalate.

What causes cracks in a cylinder head?

Cracks in the cylinder head are often caused by overheating and thermal stress, especially in engines with materials like cast iron and aluminum. Prolonged exposure to high temperatures can weaken the material, leading to cracks.

How can I prevent cylinder head issues?

Preventative measures include regular inspections and maintenance, monitoring engine temperature, and performing coolant flushes. Ensuring proper cooling system function can significantly reduce the risk of cylinder head problems.

When should I consult a mechanic about cylinder head issues?

You should consult a mechanic if you notice symptoms like overheating, significant oil leaks, or changes in engine performance. Early professional assessment can prevent minor issues from becoming major engine problems.

What repair options are available for cylinder head problems?

Repair options vary depending on the issue severity. For minor problems, you might replace gaskets or conduct DIY fixes. Serious issues may require resurfacing or complete replacement of the cylinder head by a qualified mechanic.