Hearing that telltale ticking sound from your engine can send chills down any car owner’s spine. Bad lifters are often the culprit behind this noise, and they’re not something to ignore. We’ve seen countless drivers wonder just how long they can continue driving when these essential engine components start to fail.

While you might be tempted to postpone repairs due to cost or inconvenience, understanding the real timeline and risks of driving with bad lifters is crucial. The answer isn’t always straightforward—it depends on several factors including the severity of the damage and your vehicle’s make and model. In this guide, we’ll help you recognize when it’s time to address the problem before you’re left stranded on the roadside with a much more expensive repair.

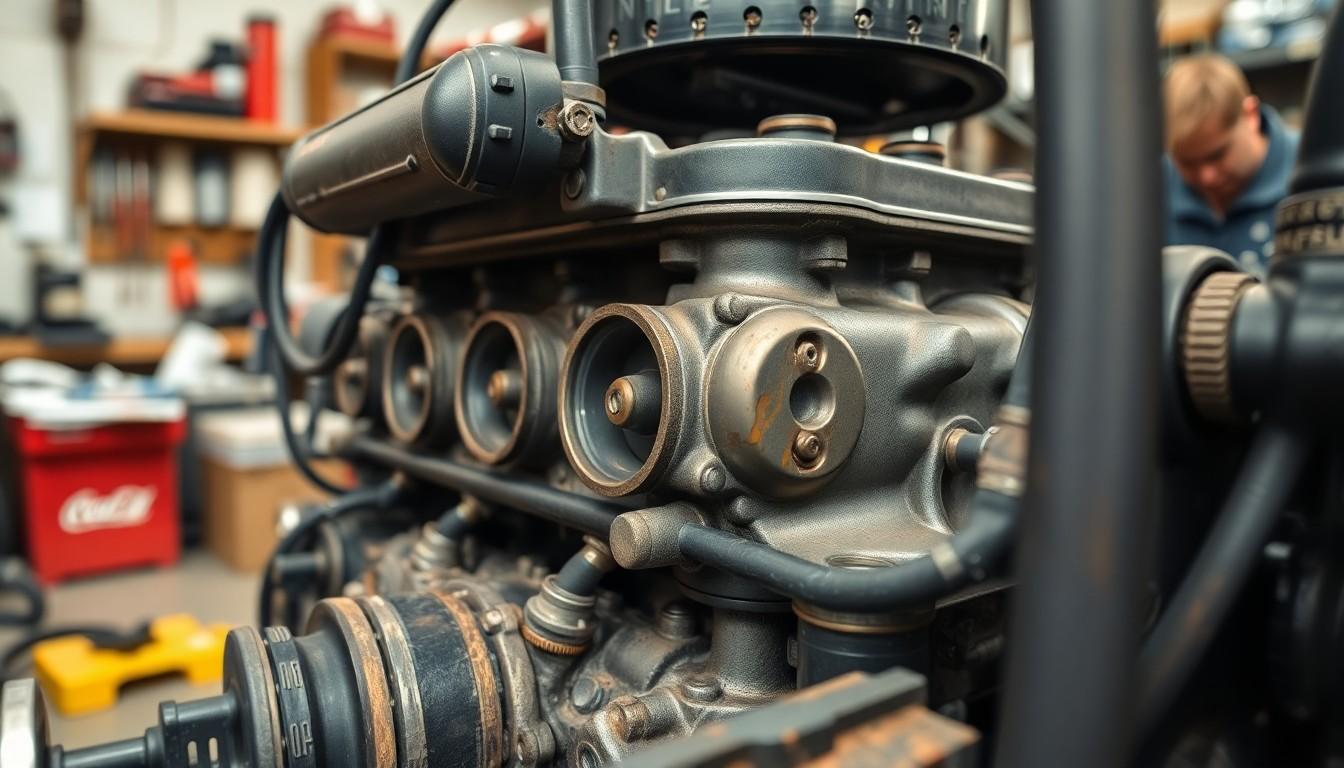

Understanding Engine Lifters and Their Function

Engine lifters play a crucial role in the valve train system of internal combustion engines. These small cylindrical components transfer motion from the camshaft to the valves, ensuring proper engine operation and performance.

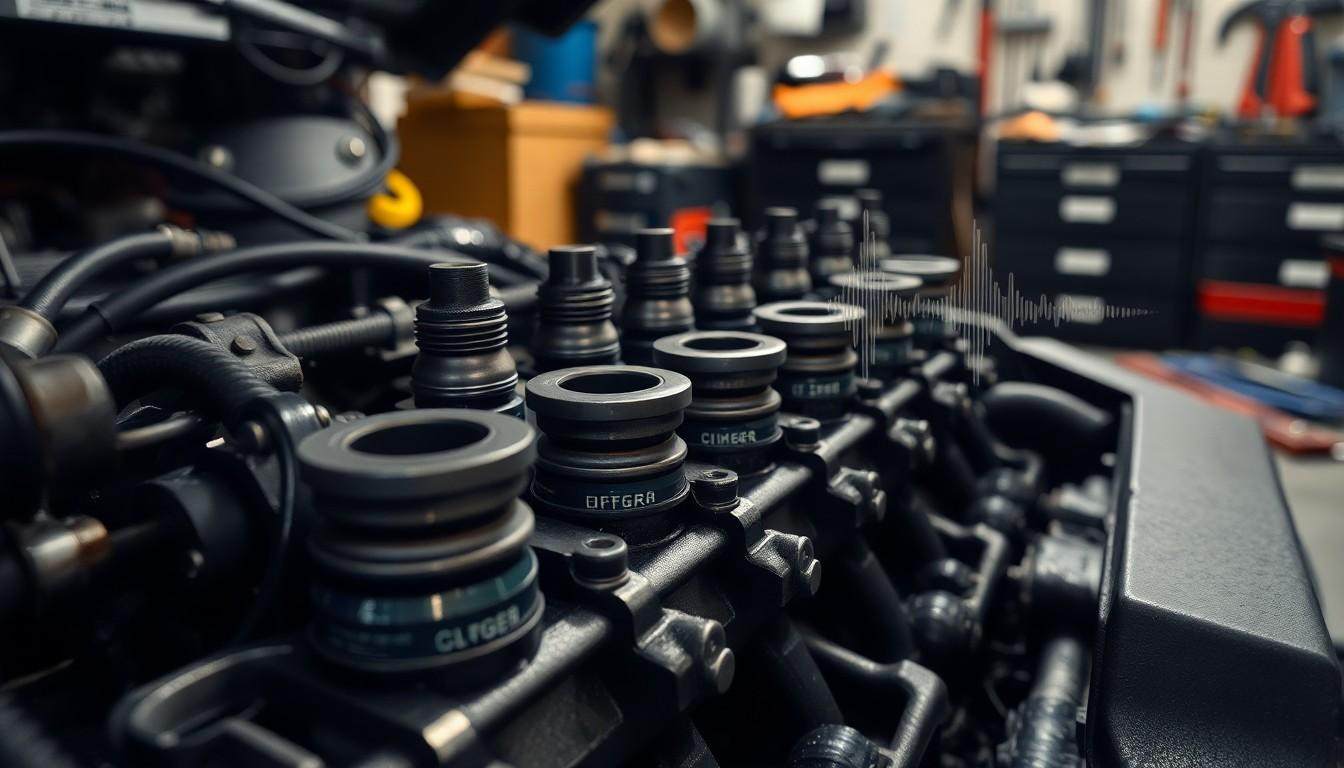

Types of Lifters in Modern Engines

Modern engines feature several types of lifters, each with distinct designs and applications. Hydraulic lifters use engine oil pressure to automatically adjust valve clearance, eliminating the need for regular adjustments. Solid lifters (mechanical lifters) maintain fixed clearances and require periodic adjustments but offer better performance at high RPMs. Roller lifters include small roller bearings that reduce friction and wear on the camshaft, improving engine efficiency and longevity. Variable valve timing systems in newer vehicles often incorporate specialized lifters that can adjust valve timing based on engine speed and load conditions.

Signs of Failing Lifters

Identifying failing lifters early helps prevent extensive engine damage. A persistent ticking noise, especially prominent during cold starts, often indicates lifter problems. Misfiring engines or rough idling occurs when bad lifters prevent valves from opening and closing properly. Decreased engine performance, including power loss and reduced acceleration, stems from improper valve operation caused by faulty lifters. Increased oil consumption might signal lifter issues, as damaged lifters can leak oil into combustion chambers. The check engine light frequently illuminates due to the engine’s irregular performance when lifters fail. These symptoms typically worsen over time, with initially intermittent noises becoming constant as the condition deteriorates.

How Long Can You Drive With Bad Lifters?

Driving with bad lifters puts your engine at important risk and isn’t recommended for extended periods. The timeline varies dramatically based on several factors, with severity of symptoms being the primary determinant.

Short-Term Driving Considerations

Bad lifters producing a slight ticking noise might allow you to drive for a few hundred miles before requiring repair. Louder noises, misfires, or rough running indicate more severe damage and substantially reduce your safe driving distance. Many mechanics recommend addressing the issue within 100-200 miles of first noticing symptoms to prevent cascading engine damage. Continuing to drive with failing lifters transforms a potentially manageable repair into a much costlier engine overhaul.

Factors That Affect Safe Driving Time

The duration you can safely drive with bad lifters depends on multiple interconnected factors. Engine performance serves as the most visible indicator—vehicles experiencing misfires, rough idling, or illuminated check engine lights require immediate attention. Different lifter types deteriorate at varying rates, with hydraulic lifters often failing due to valve train lash issues. Maintenance history plays a crucial role, as engines receiving regular oil changes and proper care typically withstand lifter issues longer than neglected engines.

Oil quality and level dramatically impact safe driving time, as poor lubrication accelerates lifter wear and subsequent failure. Driving habits also matter—aggressive acceleration, high-speed driving, and heavy loads place additional stress on compromised lifters. The risks of continued driving include valve misalignment, improper timing, and critical internal engine damage affecting the camshaft and valves, potentially resulting in complete engine failure that costs thousands to repair.

Risks of Continuing to Drive With Bad Lifters

Driving with bad lifters exposes your vehicle to important risks that extend beyond mere noise or discomfort. These risks can lead to substantial mechanical failures and safety hazards that compromise both your vehicle’s longevity and your personal safety.

Potential Engine Damage

Bad lifters cause severe engine damage when left unaddressed. The roller on defective lifters can directly damage the camshaft, creating a destructive chain reaction throughout your engine system. Valve misalignment results from improper lifter function, causing misfires and reduced power output that worsens with each mile driven. Excessive valve lash produces knocking and rattling sounds while accelerating part wear and creating a rougher driving experience. Critical internal engine components face increasing strain, especially when the valves and camshaft operate with improper timing due to lifter failure. Complete engine failure represents the worst-case scenario, with repair costs potentially reaching thousands of dollars for what began as a relatively simple lifter issue.

Safety Concerns on the Road

Road safety decreases significantly when driving with faulty lifters. Reduced power output makes your vehicle less reliable in situations requiring quick acceleration or consistent performance. Unpredictable engine behavior poses serious risks during crucial driving moments, potentially leading to sudden failures or loss of control in traffic. Engine performance becomes increasingly erratic as lifter damage progresses, affecting your ability to maintain consistent speeds or respond to traffic conditions. Component failures extend beyond the engine itself, potentially damaging the catalytic converter and other essential systems that ensure safe vehicle operation. Emergency situations become more dangerous when your vehicle can’t reliably perform due to lifter-related issues, placing you and other road users at unnecessary risk.

Cost Comparison: Immediate Repair vs. Delayed Maintenance

Comparing the costs between fixing bad lifters immediately and postponing repairs reveals a important financial difference. Making an well-informed choice requires understanding both short-term expenses and potential long-term consequences.

Immediate Repair

Replacing faulty lifters requires professional attention and represents a substantial initial investment. The cost typically ranges between $1,000 and $2,500, varying based on your vehicle’s make, model, and year. This expense covers not just the replacement of the defective lifters but also includes necessary adjustments to prevent future issues. Though this upfront cost might seem high, it’s often the most economical choice when considering the alternative scenarios.

Delayed Maintenance

Postponing lifter repairs creates a cascade of increasingly expensive problems beyond the initial issue. Continual operation with bad lifters damages critical engine components, resulting in repair bills that far exceed the cost of addressing the original problem. Damaged catalytic converters require additional repairs that wouldn’t be necessary with timely maintenance. Camshaft and valve damage becomes almost inevitable as failing lifters continue affecting these connected components. The most severe consequence—complete engine failure—can necessitate a full engine replacement, with costs potentially exceeding $5,000 to $10,000, dwarfing the expense of early intervention.

Long-Term Financial Impact

The financial implications of delayed lifter maintenance extend far beyond immediate repair costs. Repair expenses increase exponentially with continued driving, as additional engine components sustain damage from improperly functioning lifters. Vehicle lifespan shortens dramatically when engine issues remain unaddressed, forcing earlier than necessary car replacements. Every mile driven with faulty lifters increases the probability of catastrophic failure, transforming what could have been a manageable repair into a major financial burden. Consistent maintenance eventually preserves both your vehicle’s functionality and your financial resources, making immediate attention to lifter problems the economically prudent choice.

When to Seek Immediate Repairs

Certain emergency symptoms serve as critical warning signs that your vehicle needs immediate professional attention. Recognizing these signals helps prevent catastrophic engine damage and keeps repair costs manageable.

Emergency Symptoms That Require Immediate Attention

Loud Noises indicate severe lifter failure that demands urgent repair. When you hear pronounced knocking, rattling, or ticking sounds coming from your engine, these acoustic warnings signal that your lifters have deteriorated significantly.

Misfires and Rough Engine Operation point to important valve train issues caused by failing lifters. Your engine’s erratic performance, including hesitation during acceleration and unstable idle, signals that valves aren’t operating properly due to lifter malfunction.

Illuminated Check Engine Light paired with other symptoms suggests serious lifter problems requiring immediate attention. This dashboard warning often appears alongside performance issues and unusual noises, serving as your vehicle’s direct communication that internal engine components are at risk.

Excessive Valve Lash creates distinctive knocking and rattling sounds that indicate advanced lifter failure. This mechanical condition occurs when the gap between valve components becomes too large, preventing proper valve operation and requiring swift professional intervention.

Ignoring these critical symptoms frequently leads to exponentially higher repair costs. What starts as a $1,000-2,500 lifter replacement can escalate to repairs exceeding $5,000 when damage extends to the catalytic converter, camshaft, and other vital engine components.

Preventative Maintenance for Lifters

Proactive maintenance is essential for preventing lifter problems and extending the life of your engine components. Regular attention to exact maintenance areas can help you avoid the costly repairs associated with lifter failure.

Regular Maintenance

Following your vehicle’s recommended maintenance schedule serves as the cornerstone of lifter health. Regular oil changes using the manufacturer-specified oil grade directly impact lifter function since these components rely on proper lubrication. Most vehicle manufacturers recommend oil changes every 3,000-7,500 miles, depending on driving conditions and oil type. Addressing minor issues during routine maintenance appointments can prevent them from escalating into major lifter problems that require extensive repairs.

Monitoring Engine Performance

Daily attention to your engine’s performance provides early warning signs of potential lifter issues. Listen for unusual noises, especially ticking sounds that become louder as engine RPMs increase. Watch for performance changes such as rough idling, hesitation during acceleration, or decreased power output. These symptoms often indicate developing lifter problems that require attention before they cause catastrophic damage to your engine’s valve train system.

Type of Lifters

Understanding your exact engine’s lifter design helps you carry out the appropriate maintenance strategies. Hydraulic lifters require clean oil with proper viscosity to maintain pressure and function correctly. Solid lifters need periodic adjustment of valve lash according to manufacturer specifications. Roller lifters benefit from high-quality lubricants that protect their moving components from premature wear. Each lifter type has unique maintenance requirements that affect their longevity and performance characteristics.

Addressing Issues Promptly

Quick response to early warning signs prevents minor lifter problems from developing into major engine damage. When you first notice ticking sounds or performance issues, consulting with a qualified mechanic can save thousands in repair costs. Postponing repairs after identifying symptoms typically leads to more extensive damage, including potential harm to the camshaft, valves, and catalytic converter. The difference between a $1,000 lifter replacement and a $5,000+ engine rebuild often comes down to addressing problems at their earliest stages.

Extending Lifter Lifespan

Proper lubrication forms the foundation of lifter longevity, with oil quality directly impacting how long these components last. Using synthetic oils can provide superior protection for lifters, especially in high-performance or high-mileage engines. Maintaining correct oil levels prevents momentary lubrication lapses that accelerate wear. Adding oil additives designed for hydraulic lifters can sometimes quiet noisy lifters and extend their functional life in older vehicles. Advanced diagnostic tools like oil analysis can detect metal particles that indicate developing lifter problems before they cause noticeable symptoms.

Conclusion

Driving with bad lifters isn’t something to ignore. While you might get away with a few hundred miles for minor issues the situation quickly deteriorates with more severe symptoms requiring attention within 100-200 miles at most.

The choice is clear: address lifter problems promptly or risk exponentially higher repair costs that can jump from $1,000-2,500 to over $5,000. Beyond financial concerns there’s also the safety risk of unpredictable engine behavior.

We’ve seen how preventative maintenance including regular oil changes and monitoring for unusual noises can help avoid these scenarios altogether. Remember that proper care of your engine’s lifters isn’t just about avoiding repairs – it’s about preserving your vehicle’s longevity and your peace of mind on the road.

Frequently Asked Questions

What are engine lifters and why are they important?

Engine lifters are crucial components in the valve train system of internal combustion engines. They transfer motion from the camshaft to the valves, controlling the timing of air and fuel intake and exhaust. Proper functioning lifters ensure smooth engine operation, optimal performance, and fuel efficiency. Without them, your engine wouldn’t be able to breathe properly, leading to power loss and potential damage.

What are the common signs of bad lifters?

The most noticeable sign is a persistent ticking noise, especially during cold starts. Other symptoms include engine misfires, rough idling, decreased performance, increased oil consumption, and an illuminated check engine light. You might also notice reduced power when accelerating and unusual vibrations. These symptoms typically worsen over time if not addressed promptly.

How long can I safely drive with bad lifters?

The safe driving distance with bad lifters depends on symptom severity. With minor ticking, you might manage a few hundred miles, but with louder noises or additional symptoms, limit driving to 100-200 miles. Factors affecting this timeline include engine condition, maintenance history, oil quality, and driving habits. The more severe the symptoms, the sooner you should seek repairs.

What risks am I taking by continuing to drive with bad lifters?

Continuing to drive with bad lifters can cause severe engine damage including camshaft wear, valve misalignment, and increased friction between components. This can lead to complete engine failure requiring a costly rebuild or replacement. Additionally, unpredictable engine behavior creates safety hazards, especially in critical driving situations where reliable power is essential for avoiding accidents.

How much does it cost to repair bad lifters?

Replacing faulty lifters typically costs between $1,000 and $2,500, depending on your vehicle make, model, and location. This includes parts and labor. While significant, this investment prevents more extensive damage. Delaying repairs can lead to additional engine damage, potentially escalating costs to $5,000-$10,000 for major engine work or full replacement.

What are the emergency symptoms that require immediate attention?

Seek immediate professional help if you experience loud knocking or banging noises, severe misfires, rough engine operation, illuminated check engine light with lifter-related codes, or distinctive knocking sounds indicating excessive valve lash. These symptoms signal advanced lifter failure that can quickly progress to catastrophic engine damage if ignored.

Can preventative maintenance help avoid lifter problems?

Absolutely. Follow your vehicle’s maintenance schedule, particularly for oil changes, as clean oil is critical for lifter function. Use high-quality oils appropriate for your engine type. Listen for unusual noises during operation, especially after cold starts. Understanding your specific lifter design helps implement appropriate maintenance strategies. Early intervention for minor issues prevents major, costly repairs later.

Do different types of lifters have different symptoms when failing?

Yes. Hydraulic lifters typically produce a distinct ticking noise when failing. Solid lifters may create more pronounced knocking sounds when adjustment is needed. Roller lifters often exhibit performance issues like rough idling before making noticeable sounds. The symptoms also vary in intensity depending on the lifter type, with hydraulic lifters generally showing symptoms earlier due to their reliance on oil pressure.

Can I replace lifters myself or is professional service required?

While technically possible for experienced DIYers, lifter replacement is generally best left to professionals. The job requires specialized tools, extensive disassembly of the engine’s top end, precise adjustments, and detailed knowledge of valve timing. Mistakes can cause significant engine damage. For most vehicle owners, professional service provides the expertise necessary for proper diagnosis and repair.

How do driving habits affect lifter longevity?

Aggressive driving, including frequent high RPM operation and rapid acceleration, increases stress on lifters. Short trips where the engine doesn’t reach optimal temperature prevent proper oil circulation to lifters. Regular highway driving at consistent speeds generally promotes better lifter health. Proper warm-up periods, especially in cold weather, ensure adequate lubrication reaches the lifters before putting them under load.