Curious about those mysterious ticking sounds coming from your engine? You’re not alone. Lifters play a crucial yet often overlooked role in your car’s engine performance. These small components make a big difference in how smoothly your vehicle runs and how long your engine lasts.

We’ve spent years diagnosing engine issues and can tell you that understanding lifters is essential for any car owner. Whether you’re hearing that dreaded tick-tick-tick or simply want to expand your automotive knowledge, you’re in the right place. In this guide, we’ll break down exactly what lifters are, how they function, and why they matter to your engine’s health.

What Are Lifters in a Car Engine: An Essential Component Explained

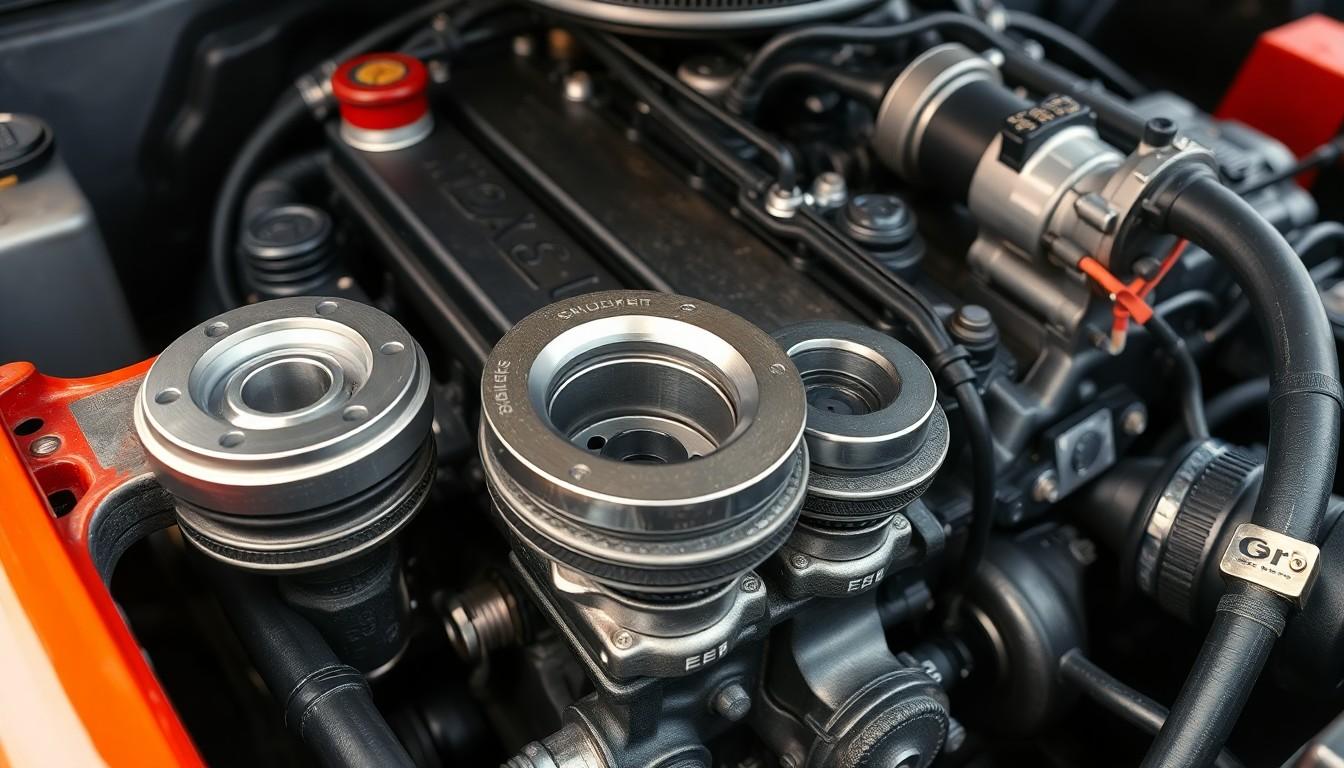

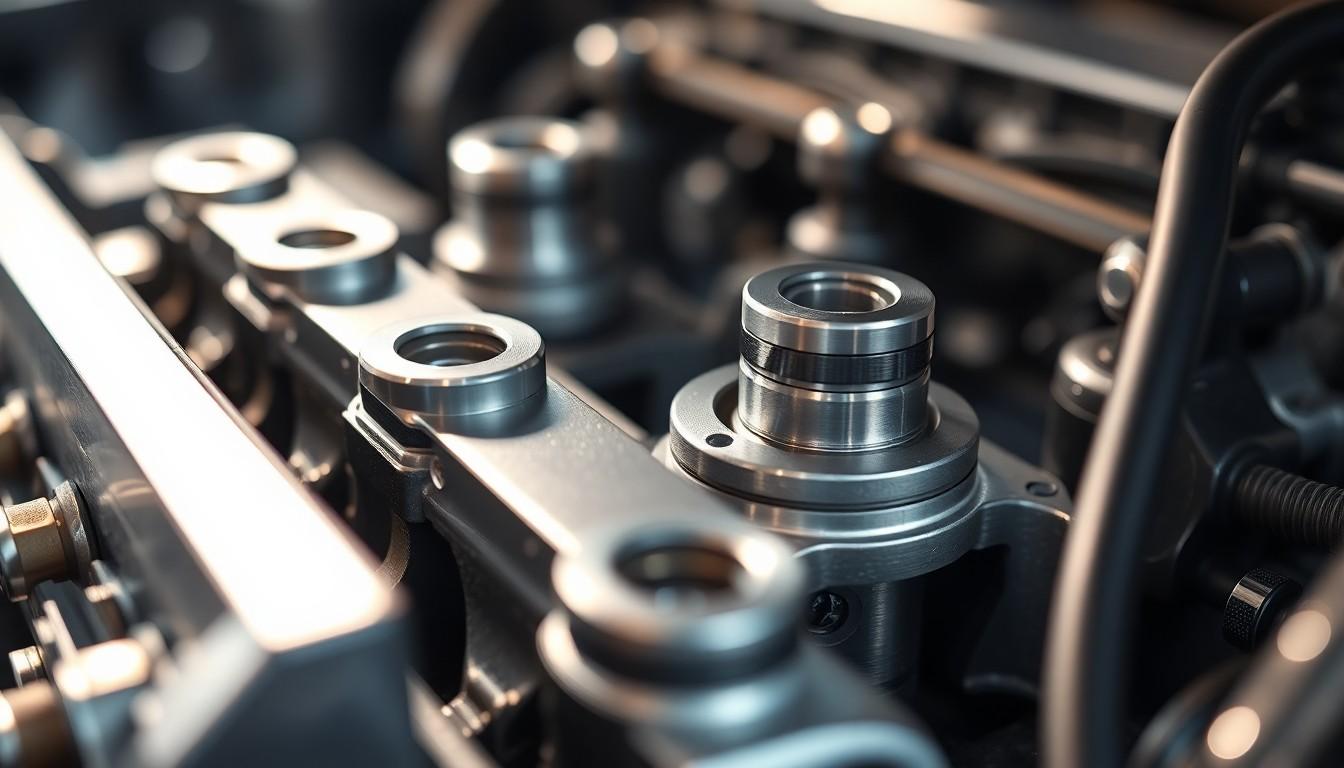

Lifters in a car engine are small cylindrical components that play a crucial role in the valve train system. These mechanical devices, also known as hydraulic valve lifters or tappets, sit between the camshaft and valve stems, transferring motion from the camshaft to open and close the engine’s valves at precisely timed intervals. Engine lifters come in several types, including hydraulic lifters, solid lifters, and roller lifters, each with exact applications and benefits.

Hydraulic lifters are the most common type found in modern passenger vehicles. They use engine oil pressure to automatically maintain zero valve clearance, eliminating the need for regular adjustments. This self-adjusting capability makes hydraulic lifters virtually maintenance-free and contributes to quieter engine operation.

Solid lifters, in contrast, don’t have internal hydraulic components. These simple mechanical devices require periodic manual adjustments to maintain proper valve clearance. Performance enthusiasts often prefer solid lifters for high-RPM applications because they don’t suffer from the “pump-up” issues that can affect hydraulic lifters at extreme engine speeds.

Roller lifters feature a small roller wheel at the point of contact with the camshaft. The roller design significantly reduces friction between the lifter and camshaft lobe, decreasing wear and improving fuel efficiency. Many modern engines use roller lifters to enhance durability and performance while meeting stringent emissions standards.

The primary function of lifters is to translate the rotational motion of the camshaft into linear motion needed to operate the valves. As the camshaft rotates, its lobes push against the lifters, which then push against the pushrods (in pushrod engines) or directly against the valves (in overhead cam engines). This precisely timed movement allows air and fuel to enter the combustion chamber and exhaust gases to exit at exactly the right moments.

The Function and Purpose of Valve Lifters

Valve lifters serve as critical intermediaries in the engine’s valve train system, transferring motion from the camshaft to the valves. These small but mighty components control the precise opening and closing of engine valves, directly impacting overall engine performance and efficiency.

How Lifters Maintain Proper Valve Timing

Lifters ensure proper valve timing by maintaining the correct clearance between the camshaft and valve train components. They follow the camshaft’s profile meticulously, converting its rotational movement into the linear motion needed for valve operation. Hydraulic lifters use engine oil pressure to self-adjust automatically, eliminating the need for manual adjustments while maintaining optimal valve clearances. This self-adjusting capability compensates for thermal expansion that occurs as engine temperatures fluctuate during operation. Proper valve timing is essential for efficient combustion, as it controls when air and fuel enter the combustion chamber and when exhaust gases exit.

The Role of Lifters in the Valve Train System

Lifters occupy a strategic position between the camshaft and pushrods in the valve train assembly. They absorb shock and vibrations from the camshaft’s movement, functioning effectively as shock absorbers for the entire valve train system. Following the camshaft’s profile, lifters push the pushrods upward, which then activate the rocker arms that eventually open and close the valves. This coordinated movement ensures that valves operate in perfect synchronization with the engine’s pistons. Lifters also compensate for wear in valve train components over time, maintaining necessary clearances even as parts experience normal degradation. Engine performance remains consistent thanks to the lifters’ ability to adapt to these changing conditions within the engine.

Types of Lifters Used in Modern Engines

Modern engines employ several types of lifters, each designed for exact applications and performance requirements. These engine components play a crucial role in valve operation and significantly impact engine efficiency, noise levels, and maintenance needs.

Hydraulic Lifters: Benefits and Operation

Hydraulic lifters feature an ingenious internal piston assembly that moves within the outer body, allowing for automatic adjustment. Pressurized engine oil enters the lifter body through a narrow channel, which closes when the cam applies pressure to the lifter piston. This self-adjusting mechanism maintains valve lash at approximately 0.006 inches, creating noticeably quieter and smoother engine operation. Hydraulic lifters automatically compensate for thermal expansion and component wear over time, maintaining zero lash in the valve train without requiring manual adjustments. Once set to the prescribed preload, these lifters typically function properly throughout the engine’s lifespan, making them ideal for everyday vehicles where low maintenance is a priority.

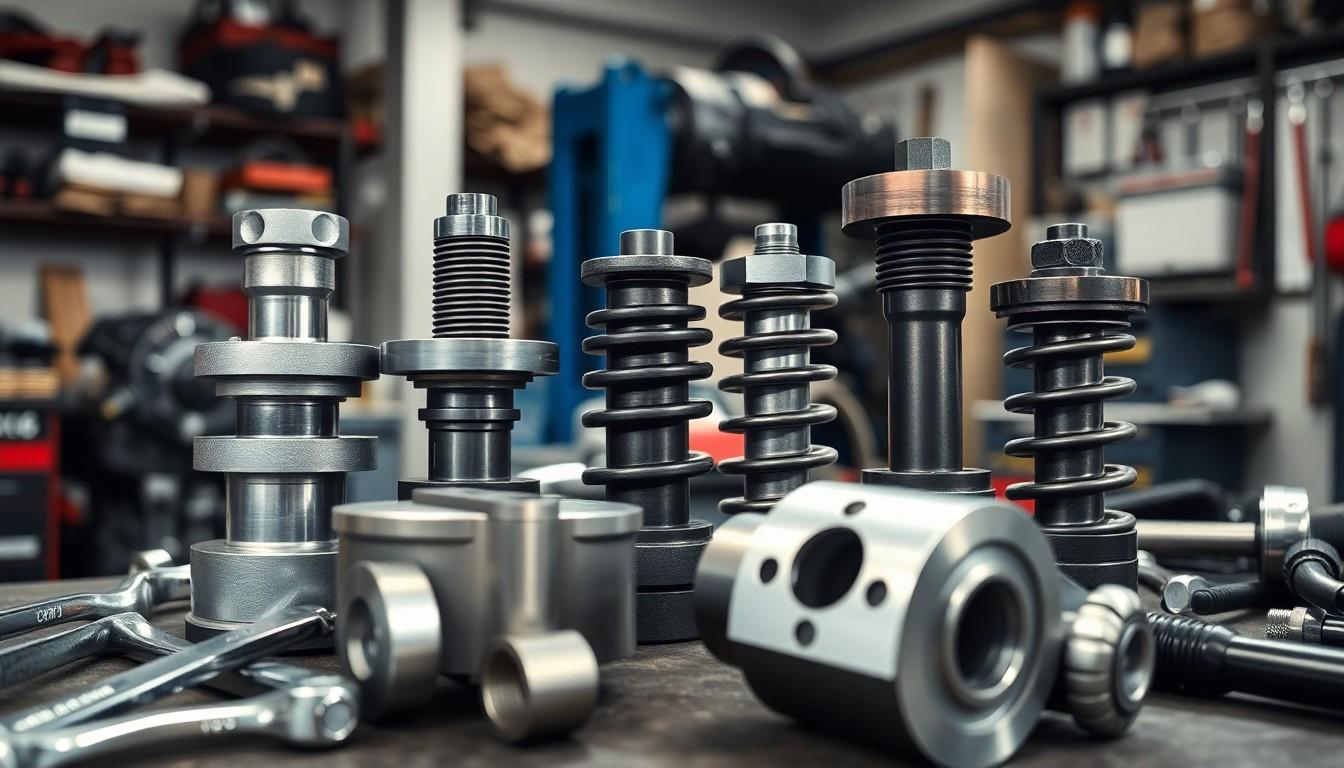

Solid Lifters: Applications and Maintenance

Solid lifters contain no internal moving parts and function as simple mechanical links between the camshaft and valves. These lifters require a exact initial valve lash setting to accommodate thermal expansion in the valve train during operation. Performance enthusiasts and racing teams often prefer solid lifters for their ability to maintain precise valve timing at high RPMs, which translates to enhanced engine performance in competitive applications. Regular maintenance forms an essential part of solid lifter ownership, as technicians must periodically adjust the valve lash to manufacturer specifications. This adjustment process demands technical expertise and can be time-consuming, representing a trade-off for the performance benefits these lifters provide.

Roller Lifters: Performance Advantages

Roller lifters transform the camshaft’s wiping force into a rolling motion through an integrated roller bearing at the contact point. This engineering approach dramatically reduces friction between the camshaft lobe and lifter, allowing for more aggressive cam profiles while minimizing wear on both components. Engines equipped with roller lifters typically demonstrate improved performance and enhanced reliability, particularly in high-stress applications where consistent valve operation is paramount. Manufacturers produce roller lifters in both hydraulic and mechanical variants, giving engineers flexibility to select the optimal configuration for exact engine designs. The reduced friction of roller lifters contributes to better fuel efficiency and power output, making them increasingly common in both performance and production engines where their benefits outweigh their additional cost.

Common Signs of Lifter Problems

Recognizing lifter problems early can save you from costly engine repairs down the road. Several telltale symptoms indicate when these crucial valve train components aren’t functioning properly.

Ticking or Tapping Noises From the Engine

Engine ticking or tapping noises rank as the most common indicator of lifter issues. These distinctive sounds typically present themselves when the engine is cold and often diminish as the engine reaches operating temperature. The noise occurs because the lifter fails to maintain proper pressure, creating excessive valve lash—the gap between valve train components. This increased clearance allows metal parts to contact each other with more force, producing the characteristic ticking sound that many drivers find concerning.

Performance Issues Related to Faulty Lifters

Faulty lifters create several performance problems that affect your vehicle’s overall operation. Reduced engine performance stems from compromised airflow into the cylinders when lifters fail to maintain precise tolerances for proper valve operation. This airflow restriction becomes particularly noticeable at higher RPMs, resulting in decreased power output and reduced efficiency in your engine’s operation.

Engine misfires often occur when malfunctioning lifters cause valves to open and close at incorrect intervals. These timing issues lead to rough idling, irregular engine operation, and a noticeably degraded driving experience. The combustion process becomes inconsistent when valves don’t operate as designed, affecting everything from acceleration to general drivability.

Increased fuel consumption happens as a direct consequence of valve operation inefficiency. When lifters don’t function correctly, your engine compensates by consuming additional fuel, leading to higher fuel costs and more frequent trips to the gas station. This reduced fuel economy serves as a hidden but financially important symptom of lifter problems that many car owners overlook until they notice their fuel gauge dropping faster than usual.

Lifter Maintenance and Replacement

Proper maintenance of engine lifters extends their lifespan and prevents costly repairs. Regular attention to these critical components helps maintain optimal engine performance and prevents the development of more serious issues.

Symptoms of Bad Lifters

Engine misfires, power loss, and hesitation are telltale signs of faulty lifters in your vehicle. A distinctive tapping or clattering noise, especially when starting the engine cold, often indicates lifter problems that require attention. These noises typically originate from the upper portion of the engine and may diminish as the engine warms up. Performance issues caused by bad lifters can progressively worsen, affecting fuel economy and overall drivability if left unaddressed.

Preventative Care for Engine Lifters

Regular oil changes form the foundation of effective lifter maintenance since hydraulic lifters depend on pressurized oil to function properly. Using the manufacturer-recommended oil type and viscosity ensures optimal lifter operation and prevents premature wear. Maintaining proper oil pressure through clean oil filters and adequate oil levels helps hydraulic lifters perform their self-adjusting function efficiently.

Oil additives marketed to quiet noisy lifters provide only temporary relief rather than fixing underlying issues. Driving with the engine at normal operating temperature before shutting it down allows oil to circulate fully through the lifter system. Following the vehicle’s maintenance schedule for tune-ups can identify potential lifter problems before they escalate into major repairs.

The Cost of Lifter Replacement

Lifter replacement ranges between $1,000 and $2,500 when performed by professional mechanics, depending on vehicle make, model, and year. Labor costs account for a important portion of this expense since accessing lifters requires substantial engine disassembly. European and luxury vehicles typically incur higher replacement costs due to specialized parts and more complex engine designs.

DIY replacement can save considerable money for those with mechanical expertise and proper tools. The procedure involves removing valve covers, pushrods, and potentially the intake manifold to access the lifters. Complete sets of replacement lifters often prove more economical than replacing individual units, ensuring consistent performance across all cylinders.

Consequences of Neglect

Continued driving with faulty lifters leads to severe engine damage, including camshaft wear and potential valve train failure. The catalytic converter can deteriorate when unburned fuel passes through due to improper valve operation caused by bad lifters. Internal engine components suffer accelerated wear from metal-on-metal contact when lifters fail to maintain proper valve clearances.

Early intervention when lifter symptoms first appear prevents cascading damage to related engine components. The relatively high cost of lifter replacement pales in comparison to the expense of rebuilding or replacing an engine damaged by neglected lifter issues.

How Lifters Impact Engine Performance and Longevity

Valve Lash Management

Lifters directly influence engine performance by controlling valve lash—the critical gap between the rocker arm and valve tip. Proper lifters maintain this clearance at approximately 0.006 inches, ensuring optimal valve timing and operation. This precise adjustment eliminates excessive play in the valve train, resulting in smoother engine operation and reduced mechanical noise. Engine efficiency improves when valves open and close exactly as designed, allowing for complete combustion cycles and proper exhaust flow.

Performance Implications

Engine RPM and oil pressure share a symbiotic relationship with lifter function. Lifters require adequate oil pressure to operate within their designed tolerances, particularly during high-RPM operation. When engine speeds exceed optimal ranges, oil may not repressurize the lifters quickly enough, creating a condition where valve operation becomes compromised. This inadequate pressurization leads to reduced airflow through the engine, power loss, and potential misfiring as the air-fuel mixture becomes inconsistent.

Warning Signs of Failing Lifters

Unusual engine noises often serve as the first indicator of lifter problems. These sounds typically manifest as rhythmic ticking or tapping that corresponds to engine speed. Misfiring or rough running conditions follow as valve timing becomes inconsistent, preventing proper combustion in affected cylinders. The check engine light frequently illuminates in response to these performance irregularities, with exact diagnostic trouble codes pointing to valve train issues. These symptoms typically arise from excessive valve lash caused by worn or damaged lifters.

Consequences of Neglected Lifter Problems

Driving with faulty lifters risks important collateral damage to critical engine components. The catalytic converter often suffers first as unburned fuel passes through due to improper valve function. Camshaft lobes experience accelerated wear when lifters fail to maintain proper contact points. Internal engine components, including pistons and valves, may eventually contact each other when timing becomes severely compromised, potentially resulting in catastrophic engine failure. Addressing lifter issues promptly typically costs between $1,000-$2,500, significantly less than the expense of rebuilding an engine damaged by prolonged lifter failure.

Lifter Design Considerations

Different lifter designs present varying reliability profiles in modern engines. Hydraulic lifters offer self-adjustment capability but require consistent oil quality and pressure to function properly. Solid lifters maintain more stable operation at high RPMs but demand regular maintenance adjustments. Certain engine designs, particularly General Motors V8 models featuring cylinder deactivation technology, experience higher rates of lifter failure due to the complex valve actuation systems. Understanding your exact engine’s lifter design helps in planning appropriate maintenance intervals to maximize engine longevity.

Conclusion

Lifters may be small components in your engine but they play an outsized role in its performance and longevity. These vital parts ensure proper valve timing while reducing friction and compensating for thermal expansion throughout your engine’s operation.

Whether your vehicle uses hydraulic solid or roller lifters understanding how they function can help you identify problems before they become expensive repairs. That distinctive ticking noise might be your engine’s way of alerting you to lifter issues that need attention.

Regular maintenance especially through proper oil changes is the most effective way to protect these critical components. By keeping your lifters in good working condition you’ll enjoy better fuel efficiency smoother operation and a longer-lasting engine that performs at its best.

Frequently Asked Questions

What are lifters in a car engine?

Lifters are small cylindrical components in the valve train system that transfer motion from the camshaft to the engine’s valves. They ensure valves open and close at precisely timed intervals, playing a crucial role in engine performance. These components help maintain proper valve timing and clearance, directly impacting your engine’s efficiency and longevity.

What are the different types of lifters?

There are three main types of lifters: hydraulic, solid, and roller. Hydraulic lifters use engine oil pressure for self-adjustment and are maintenance-free. Solid lifters require manual adjustments and are preferred for high-RPM applications. Roller lifters feature a roller wheel design that reduces friction and improves fuel efficiency. Each type serves specific applications and offers unique benefits.

What does a lifter do in an engine?

Lifters convert the camshaft’s rotational motion into linear motion needed to operate valves. They maintain proper valve timing by ensuring correct clearance between components, following the camshaft’s profile precisely. Lifters also act as shock absorbers within the valve train, absorbing vibrations and maintaining synchronization between valves and pistons, which is essential for efficient combustion.

What are common signs of lifter problems?

The most common sign is a ticking or tapping noise from the engine, especially when cold. Other symptoms include reduced engine power, misfires, increased fuel consumption, and rough idling. These issues occur because faulty lifters disrupt proper valve operation, leading to combustion inefficiency. If you notice these symptoms, it’s advisable to have your vehicle inspected promptly.

How much does it cost to replace lifters?

Lifter replacement typically costs between $1,000 and $2,500, depending on your vehicle make and model. The high cost reflects the labor-intensive nature of the job, as it often requires significant disassembly of the engine. DIY options exist for those with mechanical skills, but professional service is recommended due to the complexity and precision required.

How do I maintain my engine lifters?

Regular oil changes are crucial, especially for hydraulic lifters that depend on clean, pressurized oil. Use the manufacturer-recommended oil type and weight. Keep up with scheduled maintenance and address any unusual engine noises promptly. Proper warm-up is also important, particularly in cold weather, as it ensures adequate oil pressure reaches the lifters before high RPM operation.

Can I drive with bad lifters?

While you can technically drive with bad lifters for a short period, it’s not recommended. Continuing to drive with failing lifters can lead to severe engine damage, including bent pushrods, damaged camshafts, and broken valve springs. What starts as a minor ticking noise can escalate to catastrophic engine failure, potentially resulting in much more expensive repairs.

How do lifters affect engine performance?

Lifters directly impact engine performance by managing valve lash—the critical gap between the rocker arm and valve tip. Properly functioning lifters ensure optimal valve timing and operation, leading to improved power output, fuel efficiency, and emissions control. They also help maintain proper combustion chamber sealing, which is essential for engine compression and overall performance.