Ever wondered what magical component keeps your wheels firmly attached to your vehicle? The answer lies in a critical part that often goes unnoticed yet plays a fundamental role in every journey you take.

We’re talking about the wheel hub assembly—the unsung hero that connects the wheel to the axle. This crucial connection point doesn’t just hold things together; it’s engineered to allow smooth rotation while bearing the entire weight of your vehicle. Without this vital component, our cars, bikes, and even wheelbarrows would simply fall apart at the first sign of movement.

Understanding Wheel and Axle Connections

Wheel and axle connections form the backbone of vehicle mobility, creating a critical junction where rotational forces transfer from the drivetrain to the wheels. These connections vary significantly across different vehicle types, with each design serving exact performance requirements and operational conditions. Modern vehicles typically employ several distinct connection methods, each with unique characteristics and applications.

Types of Wheel-to-Axle Connections

Wheel-to-axle connections come in various configurations depending on the vehicle’s design and purpose. Fixed connections permanently attach the wheel to the axle, allowing them to rotate as a single unit – commonly found in many toy vehicles and some industrial equipment. Bearing-supported connections use wheel bearings to create a smooth interface between the stationary axle and the rotating wheel, reducing friction and enabling independent wheel movement. Hub-centric connections align the wheel precisely with the hub using a center bore that matches the hub diameter, ensuring proper weight distribution and minimizing vibration during operation.

The Role of Wheel Bearings

Wheel bearings serve as critical intermediaries between wheels and axles, enabling smooth rotation while supporting substantial loads. These precision-engineered components contain hardened steel balls or rollers that reduce friction between moving parts, allowing wheels to spin freely with minimal resistance. Ball bearings distribute load across many small spheres and excel in high-speed applications where efficiency is paramount. Roller bearings use cylindrical rollers instead of balls, providing greater load-bearing capacity for heavier vehicles and equipment. Tapered roller bearings combine radial and thrust load capabilities, making them ideal for automotive wheel applications where forces come from multiple directions.

Hub Assemblies and Their Components

Hub assemblies integrate multiple components into a single unit that connects wheels to axles while enabling controlled rotation. The hub center forms the core structure, featuring mounting points for the wheel and connection interfaces for the axle. Bearing races provide precisely machined surfaces where bearings roll, ensuring smooth operation and proper load distribution. Mounting flanges offer secure attachment points where wheel studs or bolts connect the wheel to the hub assembly. Seals and dust caps protect the internal components from contaminants, moisture, and debris that could compromise bearing performance or cause premature failure.

CV Joints and Axle Connections

CV (Constant Velocity) joints enable smooth power transmission through varying angles between the transmission and wheels. These specialized joints transfer torque at consistent speeds regardless of suspension movement or steering angles. Inner CV joints connect the transmission to the axle shaft, accommodating minor angular changes during vehicle operation. Outer CV joints link the axle shaft to the wheel hub, handling both angular movement and in-out sliding motion during steering. The axle shaft connects these joints, creating a complete power transfer path from the vehicle’s drivetrain to its wheels while maintaining flexibility for suspension movement and steering functions.

Types of Wheel-to-Axle Connections

Wheel-to-axle connections vary significantly across different vehicle designs and purposes. These connections determine how power transfers from the drivetrain to the wheels and how the vehicle handles during operation.

Live Axles

Live axles represent one of the most common wheel-to-axle connection types in many vehicles. They feature half-shafts connected to wheels within a metal tube (axle housing) that maintains their coaxial alignment regardless of suspension movement. This rigid design provides exceptional durability for heavy-duty applications like trucks and off-road vehicles. The axle housing protects the internal components from environmental damage while ensuring proper wheel alignment under varying load conditions.

Independent Suspension

Independent suspension systems allow each wheel to move vertically without affecting the opposite wheel. In these configurations, half-shafts connect to wheel knuckles through CV joints rather than through a solid axle housing. The wheels attach to these knuckles, creating a connection that accommodates varied terrain while maintaining optimal tire contact with the road surface. Modern passenger cars predominantly use independent suspension for improved ride comfort and handling characteristics.

Trailer Axles

Trailer axles feature specialized connection designs based on their intended load capacity and application. These connections use different axle beam types—straight, bent, torsion, or drop axles—to achieve proper wheel spacing and load distribution. Straight axles provide simplicity and strength for standard applications, while drop axles lower the trailer’s center of gravity. Torsion axles incorporate rubber cords within the axle beam to absorb road shocks without traditional suspension components.

Hub Assemblies

Hub assemblies function as crucial interface components between wheels and axles. The central hole of the hub fits precisely onto the axle, while its outer portion connects to the wheel using lug nuts and studs. Modern hub assemblies often integrate multiple components including bearings, seals, and ABS sensors into a single unit. These pre-assembled units simplify installation and maintenance while ensuring proper wheel alignment and rotation.

Wheel Bearings

Wheel bearings play an essential role in wheel-to-axle connections by enabling smooth rotation while supporting vehicle weight. These precision components sit inside the hub assembly, reducing friction between the stationary and rotating parts. Tapered roller bearings handle both radial and axial loads in most automotive applications, while ball bearings offer lower friction for lighter-duty vehicles. Proper bearing selection and maintenance directly impact wheel performance, vehicle handling, and safety.

Spindles and Studs

Spindles form vital connection points in front axle assemblies where wheels rotate. These components extend from stub axles that connect to the front axle assembly through kingpins, providing the mounting surface for the wheel hub. Studs project outward from the hub assembly, creating secure attachment points for wheels. The threaded design of these studs allows lug nuts to be tightened with precise torque specifications, ensuring wheels remain firmly attached during operation. Both components must maintain exact specifications to prevent vibration, uneven tire wear, and potential safety hazards.

The Critical Role of Wheel Hubs

Wheel hubs serve as the critical connection point between your vehicle’s wheels and axles. These essential components not only secure the wheels to the axle but also support the entire weight of the vehicle while allowing wheels to rotate smoothly during operation.

How Wheel Hubs Function

Wheel hubs function through multiple integrated mechanisms that work together to enable vehicle mobility. They provide a solid mounting surface for the wheel, ensuring it’s securely attached to the axle with proper alignment. Inside the hub, bearings reduce friction between stationary and moving parts, facilitating smooth rotation around the axle. The hub assembly also plays a crucial role in distributing the vehicle’s weight evenly across the wheels, maintaining stability during both straight-line driving and cornering maneuvers.

Different Hub Types for Various Vehicles

Standard hubs equip most passenger vehicles and contain ball or roller bearings designed for everyday driving conditions. Trailer hubs feature a heavier-duty construction specifically engineered to handle the additional weight and stress associated with towing applications. CV hubs integrate with constant velocity joints in front-wheel drive vehicles, allowing for smooth power transmission at various steering angles. These specialized hub designs accommodate the unique requirements of different vehicle types, ensuring optimal performance regardless of application. Each hub type incorporates exact bearing configurations and mounting systems customized to its intended use case, from lightweight passenger cars to heavy-duty commercial vehicles.

Wheel Bearings: The Unsung Heroes

Wheel bearings serve as the crucial connection point between the wheel and the axle, enabling smooth rotation while reducing friction. These small but mighty components consist of rolling elements positioned between inner and outer metal races, creating a secure yet ever-changing interface that supports the vehicle’s weight during motion.

Roller Bearings vs. Ball Bearings

Roller bearings excel at carrying heavier loads thanks to their larger contact surface with the races. They come in several configurations including cylindrical, spherical, tapered, and needle styles, each designed for exact applications. These bearings typically appear on non-driven wheels where load capacity takes priority over rotational speed.

Ball bearings, in contrast, feature spherical rolling elements that create minimal contact points with the races. This design results in reduced rolling resistance and makes them ideal for applications where speed matters more than maximum load capacity. Most driven wheels use ball bearings since they offer superior performance at higher rotational speeds with less friction, improving overall drivetrain efficiency.

Signs of Failing Wheel Bearings

Unusual noises often signal the first warning of bearing failure, manifesting as grinding, growling, or whining sounds that become more pronounced during turns or as speed increases. Vibrations through the steering wheel or entire vehicle body indicate deteriorating bearings that no longer provide smooth rotation.

Excessive play in the wheel becomes noticeable when a failing bearing allows unusual movement when the wheel is lifted and manually rocked. Heat generation represents another telltale sign, with the hub area becoming uncommonly hot to touch after driving, sometimes accompanied by a distinctive burning odor.

ABS warning lights may illuminate unexpectedly when bearing failure affects wheel speed sensors mounted within the hub assembly. These sensors rely on proper bearing operation to accurately measure rotation, so bearing problems can trigger false readings and activate dashboard warnings. Early detection of these symptoms helps prevent more serious mechanical failures and maintains vehicle safety standards.

Fastening Systems: Lug Nuts and Bolts

Fastening systems are the critical components that secure wheels to axles, ensuring safe vehicle operation. These systems rely on precisely engineered parts that work together to create a secure connection capable of withstanding the tremendous forces experienced during driving.

Wheel Bolts

Wheel bolts serve as primary connectors between the wheel hub and axle. They feature specialized tapered heads designed for exact alignment, creating a robust connection that maintains stability even under substantial loads. The tapered design ensures proper seating against the wheel, preventing loosening during operation and distributing pressure evenly across the mounting surface. These bolts must be correctly matched to both the wheel and hub specifications to maintain proper fitment and safety.

Studs

Studs provide enhanced security in wheel-to-axle connections compared to standard bolts in many applications. These double-threaded components screw directly into the hub on one end while the other end extends outward to accept lug nuts. This dual-connection design creates a more stable mounting point and simplifies wheel installation, as the studs remain fixed to the hub when the wheel is removed. Studs are manufactured from high-strength steel to withstand the important rotational and lateral forces experienced during braking and cornering.

Lug Nuts

Lug nuts complete the wheel attachment system by threading onto studs and securing the wheel firmly against the hub. They come in various configurations including conical seat, ball seat, and flat seat designs, each engineered for exact wheel and hub combinations. The seat type must match the wheel’s lug holes to ensure proper contact and pressure distribution. Premium lug nuts often incorporate anti-theft features or specialized materials like chromoly steel for applications requiring maximum strength and durability.

Torque Specifications and Their Importance

Torque specifications represent precise tightening requirements for wheel fasteners that are critical for safety and performance. Under-torqued fasteners can work loose during operation, while over-torqued components may stretch studs or damage wheels. Manufacturers establish exact torque values based on extensive testing to determine the optimal clamping force needed for each vehicle application. Following these specifications prevents common issues like warped rotors, damaged studs, and catastrophic wheel separation.

Proper torque application ensures optimal distribution of clamping forces and maintains the integrity of the wheel-to-axle connection. Advanced assembly facilities use specialized tools for precise torque application, including calibrated torque wrenches and automated screwdriving systems that monitor torque values during installation. These tools apply consistent force according to manufacturer specifications, ensuring reliable connections across a range of applications from passenger vehicles to heavy-duty trailers.

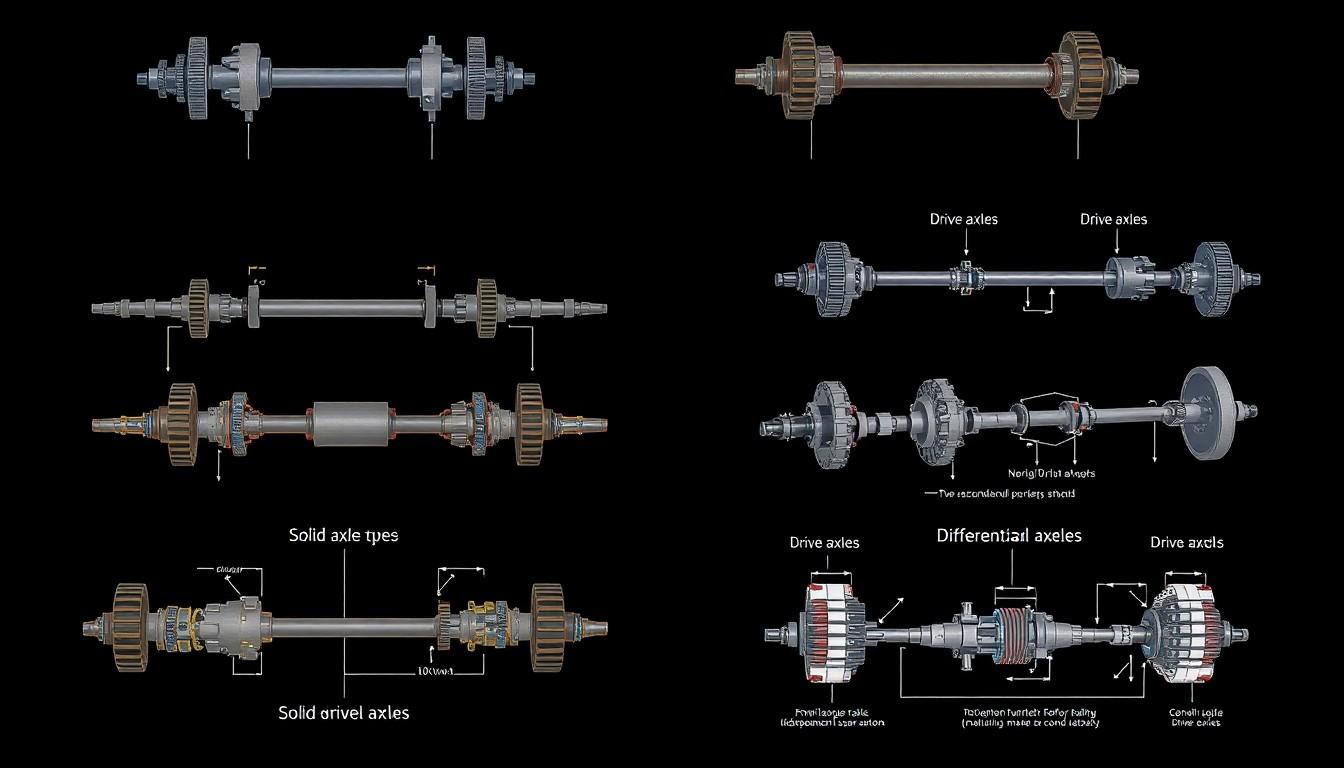

Axle Types and Their Connection Methods

Axle types play a decisive role in how wheels connect to a vehicle’s drivetrain system. Different axle configurations employ distinct connection methods that affect vehicle performance, handling, and load capacity.

Solid Axles vs. Independent Suspension

Solid axles create a rigid connection between opposing wheels through half-shafts housed within a metal tube called the axle housing. These half-shafts remain coaxial regardless of suspension movement, maintaining consistent alignment between wheels. The differential delivers torque from the power source to these half-shafts, which then transfer power to the wheels themselves. Pickup trucks and truck-based SUVs commonly use solid axles due to their durability and load-bearing capabilities.

Independent suspension systems use a fundamentally different connection approach. The half-shafts in these systems can move freely as the wheels travel through their suspension range. No housing constrains the half-shafts; instead, the suspension connects directly to the knuckles that attach to the wheels. This configuration allows each wheel to respond individually to road conditions, providing improved comfort and handling characteristics in modern cars and certain SUVs.

Drive Axles vs. Non-Drive Axles

Drive axles incorporate the mechanical components necessary to power the wheels they support. Each wheel connects to a half-shaft that links to the differential, creating a power delivery path from the engine to the wheels. These axles actively participate in vehicle propulsion by transmitting torque from the drivetrain to the road surface.

Non-drive axles, also called dead axles, lack power transmission capabilities. The wheels move with the axle tube, but these axles contain no shafts, half-shafts, or differential components inside their housing. Trailers commonly use non-drive axles since they don’t require powered wheels. Many vehicles also employ non-drive axles for wheels that don’t contribute to propulsion, focusing solely on supporting vehicle weight and maintaining directional stability.

In specialized configurations like Elliot and Reverse Elliot stub axles, the connection methods vary further. Elliot stub axles fit inside the yoke of the main axle, secured by a kingpin and cotter. Reverse Elliot designs feature the stub axle with the yoke fitting around the main axle. Lamoine stub axles use L-shaped spindles connected to the axle with kingpins and cotters that simultaneously lock the axle in position.

Maintenance Tips for Wheel-Axle Connections

Regular maintenance of wheel-axle connections ensures vehicle safety and prevents costly repairs. These connections require periodic inspection and proper care to maintain optimal performance.

Inspecting the Hub and Bearings

Hub and bearing inspections should occur at regular service intervals to catch potential issues early. Look for signs of wear such as excessive heat, unusual noises, or vibrations during operation. Proper lubrication of the hub is essential for preventing premature bearing wear and extending component life. During inspections, check that the hub remains properly seated against the axle without any visible gaps or misalignment.

Tightening the Hub

Secure fastening of the hub to the axle prevents uneven wear patterns and potential component failure. Follow manufacturer-exact guidelines when tightening hub bolts or nuts to achieve the proper connection. Loose hub connections often lead to wobbling wheels, accelerated bearing wear, and unsafe driving conditions. Check hub tightness periodically, especially after wheel service or traveling on rough terrain.

Checking the Wheel

Wheels must sit properly on the hub with evenly tightened lug nuts to maintain alignment. Use a star pattern when tightening lug nuts to distribute pressure evenly across the wheel surface. Inspect wheels regularly for signs of damage or corrosion at contact points with the hub. Proper wheel seating on the hub creates a uniform connection that prevents vibration and maintains balanced rotation.

When to Replace Wheel Bearings

Wheel bearings require replacement when unusual noises like grinding or humming emerge from the wheel area. Noticeable vibrations felt through the steering wheel or chassis often indicate bearing failure that needs immediate attention. Excessive play or looseness in the wheel represents a critical sign that bearings have worn beyond safe limits. Heat generation around the wheel hub signals bearing damage, as properly functioning bearings maintain normal operating temperatures. Vehicles pulling to one side during straight-line driving might indicate bearing failure affecting wheel alignment. ABS warning lights sometimes illuminate when wheel bearing sensors detect abnormal operation.

Proper Torquing Techniques

Torque application for wheel components follows exact procedures to ensure safety and performance. When torquing lug nuts, use a calibrated torque wrench set to the manufacturer’s specified value rather than relying on estimation. Apply torque in a star or cross pattern, tightening opposite sides sequentially to create even pressure distribution across the wheel. Hub bolts and nuts require similar precision, adhering strictly to recommended torque specifications to prevent bearing damage. Over-tightened components can distort bearing races or hubs, while under-tightened connections create unsafe operating conditions. Recheck torque settings after the first 50-100 miles following any wheel service to account for initial settling.

Conclusion

The wheel-to-axle connection represents the foundation of vehicular mobility through sophisticated engineering that balances strength durability and performance. From wheel hubs and bearings to fastening systems and specialized axle configurations each component plays a vital role in the safe operation of our vehicles.

Understanding these connections isn’t just technical knowledge—it’s essential for maintaining vehicle safety and preventing costly repairs. Whether you drive a passenger car use a trailer or operate a heavy-duty truck the principles remain consistent.

By caring for these critical connections through proper maintenance regular inspections and adherence to torque specifications we can ensure our vehicles deliver reliable performance for years to come. The humble wheel-axle connection may be hidden from view but it’s truly what keeps us moving forward.

Frequently Asked Questions

What is a wheel hub assembly and why is it important?

A wheel hub assembly is the critical component that connects your vehicle’s wheel to the axle. It ensures smooth wheel rotation while supporting the vehicle’s weight. This often-overlooked part is essential for proper vehicle function, as it integrates bearings and mounting points into a single unit. Without a functioning hub assembly, your wheels couldn’t rotate properly, making your vehicle inoperable.

How do I know if my wheel bearings are failing?

Look for five key warning signs: unusual noises (grinding or humming), steering wheel vibrations, excessive play in the wheel, abnormal heat around the wheel area, and illuminated ABS warning lights. Most bearing failures start with a subtle noise that gets louder over time. If you notice any of these symptoms, have your vehicle inspected promptly to prevent more extensive damage.

What’s the difference between roller bearings and ball bearings?

Roller bearings use cylindrical rollers between inner and outer races, making them excellent for carrying heavy loads but with slightly more friction. Ball bearings use spherical balls that provide less contact surface, creating less friction and allowing higher speeds but with lower load capacity. Your vehicle’s specific application determines which type is used in different locations.

Why is proper torque so important when tightening lug nuts?

Proper torque ensures wheels stay securely attached while preventing damage to components. Under-torquing can lead to wheel separation—a dangerous situation where wheels actually come off while driving. Over-torquing can stretch fasteners, warp rotors, and damage wheel hubs. Always use a calibrated torque wrench and follow manufacturer specifications for your specific vehicle.

What’s the difference between solid axles and independent suspension?

Solid axles provide a rigid connection where both wheels are attached to the same axle beam, offering superior durability and load-carrying capacity ideal for trucks and off-road vehicles. Independent suspension allows each wheel to move separately, providing better ride comfort, handling, and road contact on uneven surfaces, making it preferred for passenger vehicles and performance applications.

How often should wheel bearings be replaced?

Most wheel bearings last between 85,000-100,000 miles under normal driving conditions, though this varies by vehicle type and driving habits. Replace bearings immediately if you notice unusual noises, vibrations, or looseness in the wheel. Some sealed hub assemblies require complete replacement when bearings fail, while serviceable bearings can be replaced individually during regular maintenance.

What causes a wheel hub assembly to fail prematurely?

Premature hub assembly failure typically results from water or contaminant intrusion, inadequate lubrication, improper installation, impact damage from accidents or potholes, or manufacturing defects. Regular exposure to harsh conditions like salt, water crossings, or extreme temperatures accelerates wear. Proper installation with correct torque specifications and avoiding deep water when components are hot can extend hub assembly life.

Can I drive with a bad wheel bearing?

No, driving with a bad wheel bearing is dangerous and not recommended. A failing bearing can seize completely without warning, potentially causing you to lose control of your vehicle. The longer you drive with a bad bearing, the greater the risk of damaging other expensive components like CV joints, transmission parts, or causing wheel separation. Have failing bearings replaced immediately.