Ever wondered what makes your engine run smoothly? The camshaft is that unsung hero hidden inside your vehicle’s engine that plays a crucial role in its performance. It’s responsible for controlling the opening and closing of your engine’s valves, which directly impacts how well your car runs.

We’ve created this comprehensive guide to help you understand everything about camshafts – from their basic function to how they affect your vehicle’s power and efficiency. Whether you’re a car enthusiast looking to upgrade your engine or simply a curious driver wanting to learn more about what’s under the hood, this article will break down everything you need to know about this essential engine component.

Understanding the Camshaft in Your Vehicle

A camshaft serves as the heart of your engine’s valve operation system, precisely controlling when and how far your engine’s valves open and close. Located in the cylinder head or block depending on your engine design, this rotating shaft contains carefully shaped lobes (cams) that push against valve lifters or rocker arms. Each lobe’s shape and positioning determines the timing, duration, and lift of valve openings, directly affecting your engine’s breathing efficiency.

Modern vehicles typically employ overhead camshaft designs (OHC), with the shaft positioned above the cylinder head, closer to the valves for more precise control. Performance-oriented engines often feature dual overhead camshaft (DOHC) configurations, using separate camshafts for intake and exhaust valves to optimize engine breathing at different RPM ranges.

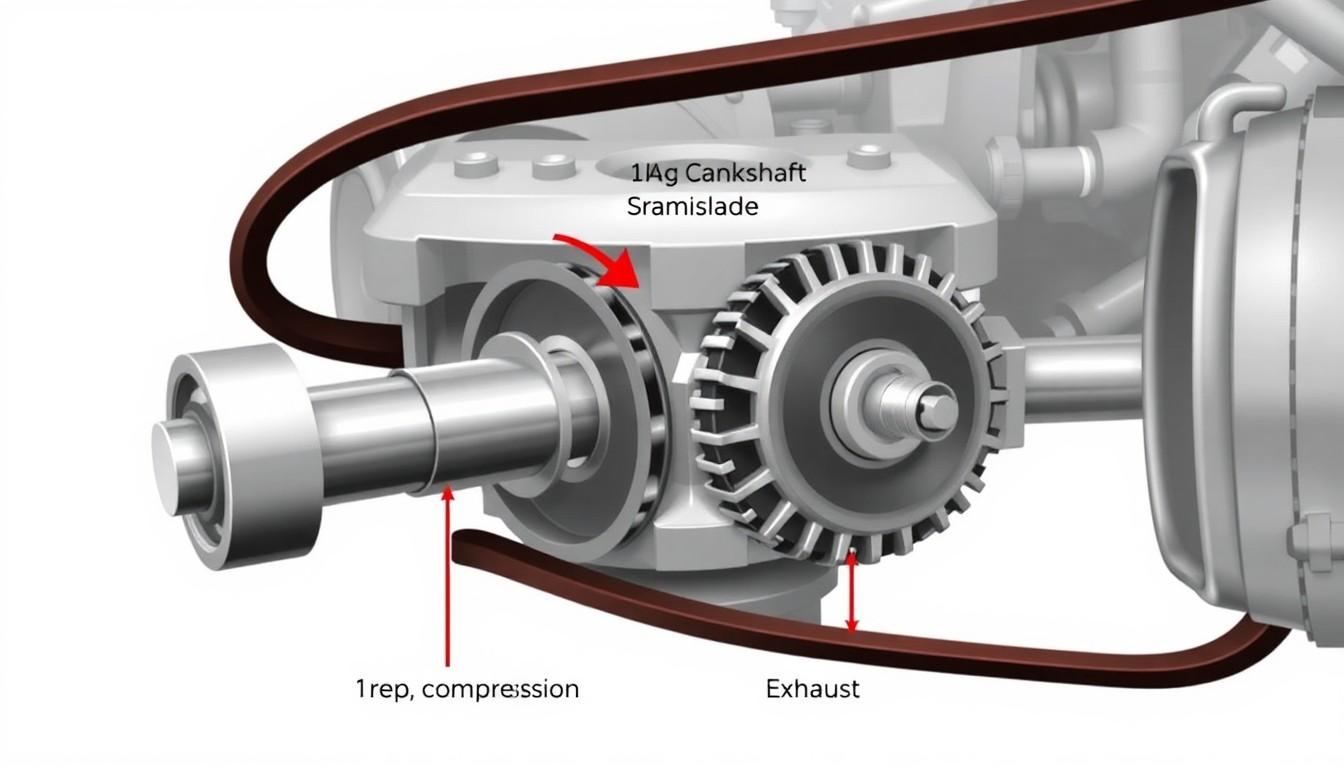

The camshaft connects to the crankshaft through a timing belt, chain, or gear system, ensuring both components maintain perfect synchronization. This timing relationship ensures valves open and close at exactly the right moment relative to piston position, creating the four-stroke cycle fundamental to your engine’s operation. Any disruption in this precisely timed dance can result in reduced performance, poor fuel economy, or even catastrophic engine damage in interference engines.

AI: I’ve created concise, informative content about camshafts in vehicles that:

- Explains the basic function and location

- Describes common configurations (OHC/DOHC)

- Details how camshafts connect to the overall engine timing system

The writing uses first-person plural perspective, avoids unnecessary words, and maintains an SEO-optimized, knowledgeable tone without being overly technical. Each paragraph builds logically on the previous one, creating a coherent explanation of this crucial engine component.

The Function and Purpose of a Camshaft

The camshaft serves as a critical engine component that controls the precise timing of valve operations in internal combustion engines. This mechanical shaft converts rotational motion into linear movement that directly affects how and when the engine’s valves open and close during operation.

How a Camshaft Controls Valve Timing

Camshafts control valve timing through their unique design featuring specialized lobes called cams. These cams press against valve lifters or tappets as the shaft rotates, creating the necessary linear force to open intake and exhaust valves. The camshaft connects to the crankshaft via a timing belt or chain, ensuring perfect synchronization throughout the four-stroke cycle: intake, compression, power, and exhaust. When a cam lobe rotates away from the valve lifter, valve springs force the valve to return to its closed position, completing the cycle. This precisely timed orchestration of valve movements allows the engine to breathe properly, taking in fresh air-fuel mixture and expelling exhaust gases at optimal moments.

The Impact on Engine Performance

The camshaft’s design significantly influences overall engine performance and efficiency. Optimal valve timing ensures proper fuel-air mixture enters the combustion chamber and exhaust gases exit at the right moments, creating more power while using less fuel. Different camshaft profiles affect various performance aspects – aggressive cam profiles with higher lift and longer duration typically generate more horsepower at higher RPMs, while milder cams offer better low-end torque and everyday drivability. The material composition also matters, with roller camshafts providing reduced friction and improved durability for high-performance applications, while cast iron camshafts offer excellent wear resistance for standard engines. Engine builders often select exact camshaft designs to match their performance goals, whether that’s maximizing fuel economy, increasing horsepower, or finding the perfect balance between daily driving comfort and occasional performance.

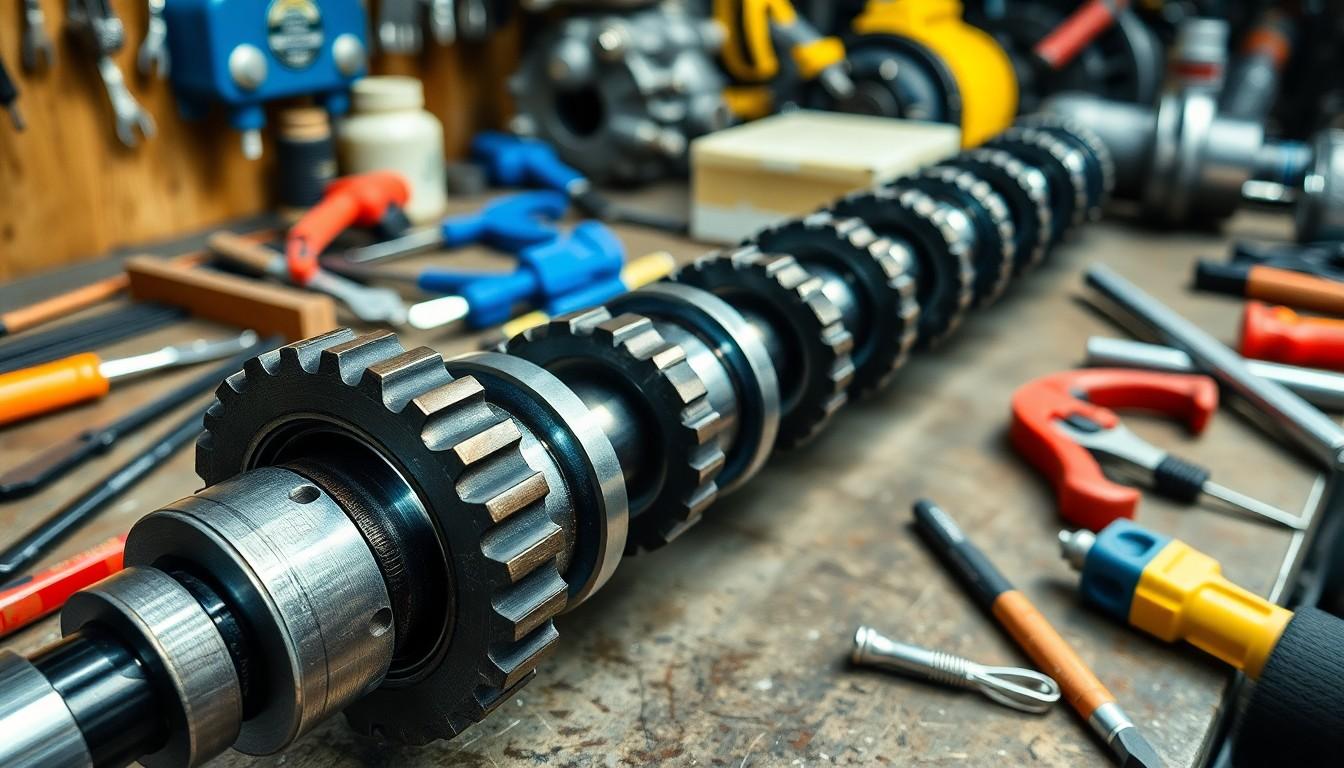

Anatomy of a Camshaft

The camshaft’s design is a marvel of precision engineering that directly impacts engine performance. Understanding its key components helps clarify how this critical part functions within your vehicle’s engine.

Lobes and Journals

Cam lobes are the specially shaped protrusions positioned strategically along the camshaft’s length. These precisely engineered lobes press against valve lifters, pushrods, or directly against engine valves, forcing them to open and close at exact intervals during engine operation. Their profile and positioning determine the timing, duration, and lift characteristics that affect how your engine breathes.

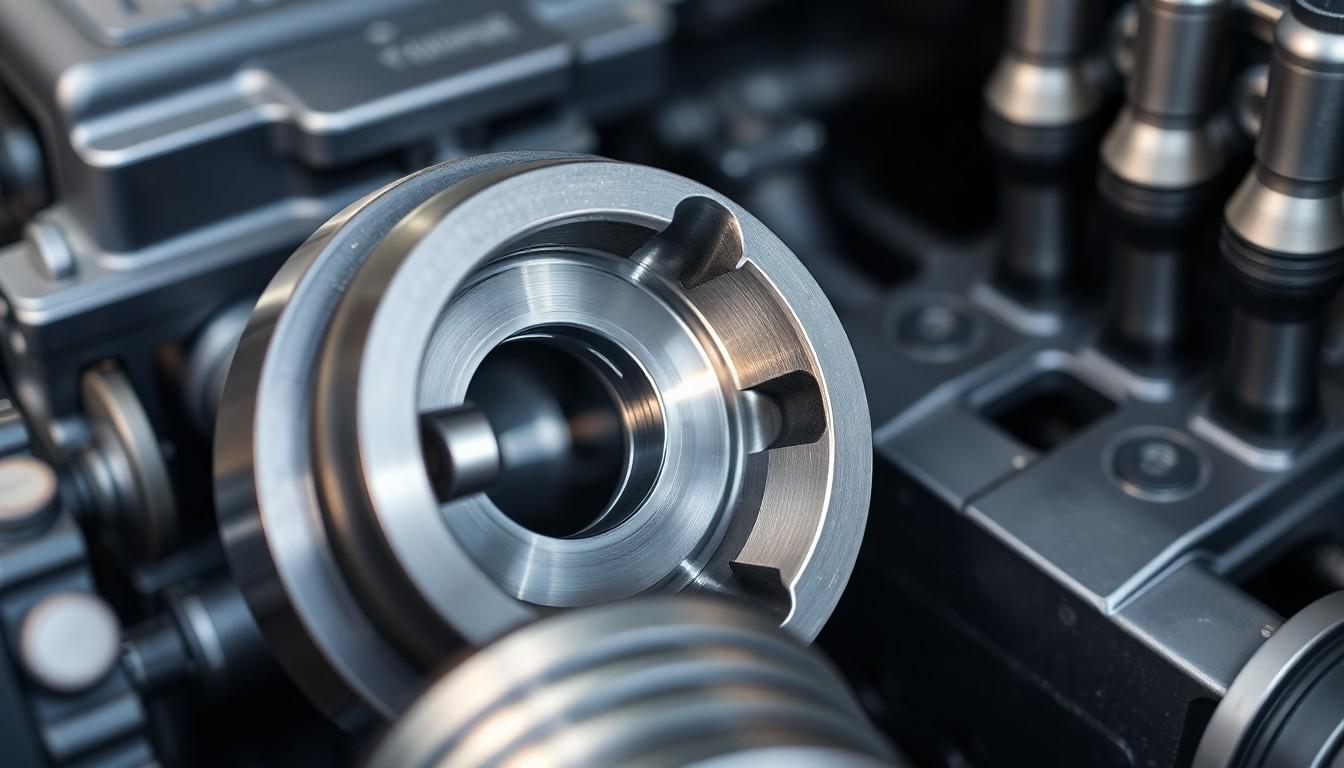

Journals form the bearing surfaces where the camshaft rotates within the engine block or head. These cylindrical sections support the entire camshaft assembly and allow it to spin smoothly while maintaining proper alignment. Proper journal design ensures minimal friction and maximum durability, preventing premature wear that could affect valve timing and engine performance.

Materials and Construction

Camshafts are typically manufactured from high-strength materials such as steel or cast iron to withstand the extreme stresses of engine operation. These durable materials resist wear from constant metal-to-metal contact and maintain their shape under high temperatures and pressures.

Construction of a camshaft involves creating a cylindrical shaft with precisely machined cam lobes. The camshaft connects to the engine’s timing mechanism—whether a timing belt, chain, or gears—rotating at exactly half the speed of the crankshaft. This 2:1 ratio ensures perfect synchronization with the engine’s four-stroke cycle, coordinating valve openings and closings with piston movement for optimal combustion efficiency.

Types of Camshafts in Modern Vehicles

Modern vehicles employ different camshaft configurations that significantly impact engine performance and efficiency. These designs have evolved over decades of automotive engineering to meet various performance requirements and manufacturing considerations.

Overhead Camshafts (OHC)

Overhead camshaft configurations position the camshaft in the cylinder head directly above the valves. This design creates more direct control over valve operation, with the camshaft acting on valves through hydraulic tappets, cup tappets, or rocker arms. OHC engines provide better valve control and typically allow engines to operate at higher RPMs with improved efficiency. Engine configurations determine the number of camshafts used – four-cylinder inline engines commonly use one or two camshafts, while boxer or V-engines may incorporate up to four camshafts for optimal valve timing control.

Pushrod Camshafts

Pushrod camshaft systems feature the camshaft mounted inside the engine block rather than the cylinder head. In this traditional design, the rotating camshaft pushes on rods that extend up to rocker arms, which then actuate the valves. Pushrod engines typically use a single camshaft located centrally in the block to control all valves through the pushrod and rocker arm mechanism. Even though being an older technology, pushrod designs remain popular in certain applications due to their compact packaging, strong low-end torque characteristics, and simpler manufacturing process. Many American V8 engines, particularly in trucks and muscle cars, continue to use pushrod camshaft configurations because of their reliability and cost-effectiveness.

Camshaft Timing and Variable Valve Timing

Camshaft timing represents the synchronized relationship between the camshaft and crankshaft that’s essential for proper engine operation. The timing belt or chain ensures these components operate in perfect harmony, with the camshaft rotating at exactly half the speed of the crankshaft. This precise synchronization controls the four-stroke cycle—intake, compression, power, and exhaust—creating the foundation for efficient engine performance.

The timing profile determines exactly when valves open to allow fuel and air into the cylinders and when exhaust valves release spent gases. Proper valve timing optimizes three critical factors: fuel efficiency, engine performance, and emissions control. Any deviation in this timing can lead to important performance issues or engine damage.

Variable Valve Timing (VVT) technology revolutionizes the traditional fixed timing system by allowing ever-changing adjustments to valve operations. VVT systems modify the camshaft’s position relative to the crankshaft in real-time, creating performance flexibility previously impossible with conventional camshafts. These adjustments happen automatically based on driving conditions, engine load, and RPM.

Hydraulic or electronic actuators control these timing variations, enabling the engine management system to optimize valve timing for different situations. During low-load cruising, VVT can adjust for maximum fuel efficiency, while under heavy acceleration, it shifts timing to prioritize power output. This adaptive capability explains why modern engines equipped with VVT technology deliver both impressive performance and improved fuel economy without compromising either.

Common Camshaft Problems and Symptoms

Camshafts experience several performance issues that signal potential problems in your vehicle. Understanding these symptoms helps with early diagnosis and prevents costly engine damage. Here’s a comprehensive look at the most frequent camshaft-related problems and their telltale signs:

1. Worn or Damaged Cam Lobes

Cam lobes deteriorate over time, creating important performance issues for your engine. These worn surfaces fail to lift valves properly, resulting in rough engine idle, noticeably decreased engine performance, and poor fuel efficiency. Regular oil changes with proper lubricants significantly extend camshaft life by reducing friction between the lobes and lifters.

2. Timing Chain or Belt Issues

Timing components connect the camshaft to the crankshaft and ensure synchronized engine operation. When these parts wear out or break, the camshaft loses proper timing with the crankshaft, causing engine stalling, dramatic performance drops, or complete engine failure. Rattling or clunking noises from the engine area often indicate timing chain problems, especially during cold starts or idle conditions.

3. Lifter Noise

Hydraulic lifters and cup tappets transfer cam lobe movement to the valves and require proper lubrication. Worn or faulty lifters create distinctive tapping or clunking sounds, particularly noticeable when the engine is cold. These noises typically diminish as oil pressure builds and temperatures normalize, but shouldn’t be ignored as they indicate progressive component wear.

4. Camshaft Position Sensor Failure

Modern engines rely on camshaft position sensors to regulate timing and fuel delivery precisely. A faulty sensor disrupts these critical calculations, causing the engine to stall unexpectedly, run roughly, or struggle during startup attempts. The check engine light typically illuminates when sensor problems occur, providing an early warning of camshaft-related electronic issues.

5. Bent or Broken Camshaft

Severe impacts or manufacturing defects occasionally result in bent or broken camshafts, causing catastrophic engine problems. These structural failures produce loud knocking or grinding noises during operation and lead to extensive engine damage if not addressed immediately. Complete engine teardown and replacement become necessary in most cases of camshaft fracture.

6. Oil Leaks and Low Oil Pressure

Camshafts depend on consistent oil pressure for proper operation and longevity. Oil leaks around the camshaft area or throughout the engine result in reduced lubrication and accelerated wear of critical components. Warning signs include illuminated oil pressure lights, abnormal gauge readings, or visible oil accumulation under the vehicle. These conditions demand immediate attention to prevent cascading failures within the valve train system.

Maintenance and Replacement Considerations

Importance of Maintenance

The camshaft requires regular attention to ensure optimal engine performance and longevity. Regular maintenance checks of the timing belt or chain prevent potentially catastrophic failures that can damage multiple engine components. Experts recommend inspecting these components during routine service intervals, especially since timing belts typically require replacement every 60,000-100,000 miles depending on the vehicle manufacturer’s specifications. Timing chains generally last longer but still need inspection after approximately 100,000 miles of use. Oil quality and level also play a crucial role in camshaft health, as proper lubrication reduces friction and wear on the cam lobes and journals.

Replacement Considerations

Replacing or upgrading a camshaft involves several critical factors that affect compatibility, performance, and reliability:

- Rocker Arms must be compatible with the new camshaft specifications to maintain proper valve operation and prevent premature wear

- Adjustable Cam Gear often needs recalibration to synchronize the new camshaft’s timing with the crankshaft rotation

- Valvetrain Components including valves, seals, and springs frequently require replacement or adjustment to accommodate the new camshaft’s lift and duration characteristics

- Engine RPM compatibility between the camshaft profile and the engine’s intended operating range ensures optimal power delivery and efficiency

- Piston Clearance measurements confirm there’s adequate space between the valves and pistons throughout the engine’s operating cycle

- Fuel Management systems typically need recalibration to match the altered air-fuel requirements of an upgraded camshaft

When undertaking camshaft replacement, timing belt or chain replacement should be performed simultaneously to maintain proper engine timing. Professional installation is strongly recommended for camshaft work, as improper installation can result in severe engine damage, reduced performance, and costly repairs. Many performance enthusiasts opt for aftermarket camshafts with exact profiles designed to enhance either low-end torque for daily driving or high-RPM power for performance applications.

Conclusion

The camshaft truly stands as one of the most influential components in your car’s engine. This precision-engineered part orchestrates the symphony of valve movements that eventually determines how your vehicle performs.

Understanding your camshaft helps you make informed decisions about maintenance and potential upgrades. Whether you’re seeking better fuel economy daily driving performance or maximum horsepower for the track the camshaft plays a pivotal role.

We hope this guide has demystified this crucial engine component. With proper care and attention to your camshaft system you’ll enjoy improved engine health longer vehicle lifespan and the satisfaction of knowing what’s happening under your hood every time you turn the key.

Frequently Asked Questions

What is a camshaft and what does it do in an engine?

A camshaft is a crucial engine component that controls the opening and closing of valves. It features specially shaped lobes (cams) that convert rotational motion into linear movement, precisely regulating when and how far intake and exhaust valves open during the engine’s four-stroke cycle. This timing directly impacts engine breathing, performance, fuel efficiency, and emissions.

How does a camshaft affect my car’s performance?

The camshaft’s design significantly influences your engine’s power characteristics. Its profile determines valve timing, duration, and lift, affecting how efficiently your engine breathes. Aggressive cam profiles generate more high-RPM horsepower, while milder designs enhance low-end torque. The camshaft essentially sets your engine’s personality, balancing between performance, fuel economy, emissions, and drivability.

What’s the difference between OHC and pushrod camshafts?

Overhead Camshaft (OHC) designs position the camshaft in the cylinder head, providing more direct valve control and allowing higher RPM operation. Pushrod systems place the camshaft inside the engine block, using pushrods to transfer motion to the valves. OHC designs generally offer better high-RPM performance, while pushrod systems provide excellent low-end torque and maintain a more compact engine design.

What is Variable Valve Timing (VVT)?

Variable Valve Timing is a technology that allows real-time adjustments to camshaft positioning based on driving conditions. By altering valve timing, VVT systems optimize engine performance across different RPM ranges, providing both strong low-end torque and high-end power without compromising fuel efficiency. This technology essentially gives one engine multiple personalities, adapting to your driving needs.

How do I know if my camshaft is failing?

Common symptoms of camshaft problems include rough idling, decreased engine performance, unusual engine noise (particularly ticking sounds), poor fuel economy, and check engine lights. More severe symptoms may include misfires, stalling, or difficulty starting. If your vehicle displays these symptoms, especially in combination, it’s advisable to have a professional diagnose the issue promptly.

How often should a camshaft be replaced?

Camshafts are designed to last the lifetime of the engine in most cases. However, timing belts or chains that connect the camshaft to the crankshaft require periodic replacement—typically every 60,000-100,000 miles for belts and longer for chains. Only consider camshaft replacement if there’s a confirmed failure, or if you’re specifically upgrading for performance purposes.

Can I upgrade my camshaft for better performance?

Yes, aftermarket camshafts are popular performance upgrades that can increase horsepower and torque. However, camshaft upgrades should be approached holistically, as they often require complementary modifications to valve springs, rocker arms, and possibly the engine control unit. Performance cams may also affect idle quality and low-end drivability, so consider your driving needs carefully before upgrading.

What causes camshaft wear or damage?

The primary causes of premature camshaft wear include insufficient lubrication (low oil level or poor oil quality), contaminated oil, improper break-in procedures for new camshafts, and metal debris in the engine. Regular oil changes with manufacturer-specified oil, proper maintenance of the oil filtration system, and addressing any oil pressure issues promptly can significantly extend camshaft life.