When it comes to engine performance, the camshaft is the beating heart that dictates how your engine breathes. Among the various camshaft designs, the flat tappet cam stands as a traditional yet effective option that’s been powering vehicles for decades. We’ll break down what makes this component unique and why it might be the right choice for your engine build.

Flat tappet cams feature a design where the lifter (or tappet) has a flat surface that contacts the cam lobe. This seemingly simple configuration actually plays a crucial role in your engine’s valve timing and lift characteristics, eventually affecting everything from idle quality to top-end power. Whether you’re restoring a classic muscle car or simply trying to understand your engine better, knowing about flat tappet cams is essential for any automotive enthusiast.

What Is a Flat Tappet Cam?

A flat tappet cam is a camshaft design where the lifter (or tappet) has a flat face that contacts the cam lobe. This traditional design has been a staple in internal combustion engines for over a century. The flat-faced lifter rides directly on the cam lobe’s surface, translating the rotational motion of the camshaft into linear motion that operates the valves.

Unlike roller cams, flat tappet designs rely on a sliding contact interface between the lifter and cam lobe. This sliding action creates exact wear patterns and requires proper lubrication to function correctly. Flat tappet cams come in two primary configurations: solid (mechanical) and hydraulic, each offering different performance characteristics and maintenance requirements.

The profile of a flat tappet cam lobe is carefully engineered with a slight taper or crown. This design feature ensures that the lifter rotates during operation, distributing wear evenly across the surface and extending the component’s lifespan. Engine builders appreciate flat tappet cams for their simplicity, cost-effectiveness, and proven reliability in many applications from classic muscle cars to vintage trucks.

Manufacturing processes for flat tappet cams typically involve precision grinding of the lobes on a cast iron or steel camshaft blank. The lobe profile determines key performance factors such as valve lift, duration, and timing events that directly influence an engine’s power curve and operating characteristics. Many performance enthusiasts choose flat tappet cams when building period-correct engines or seeking authentic sound and power delivery in restoration projects.

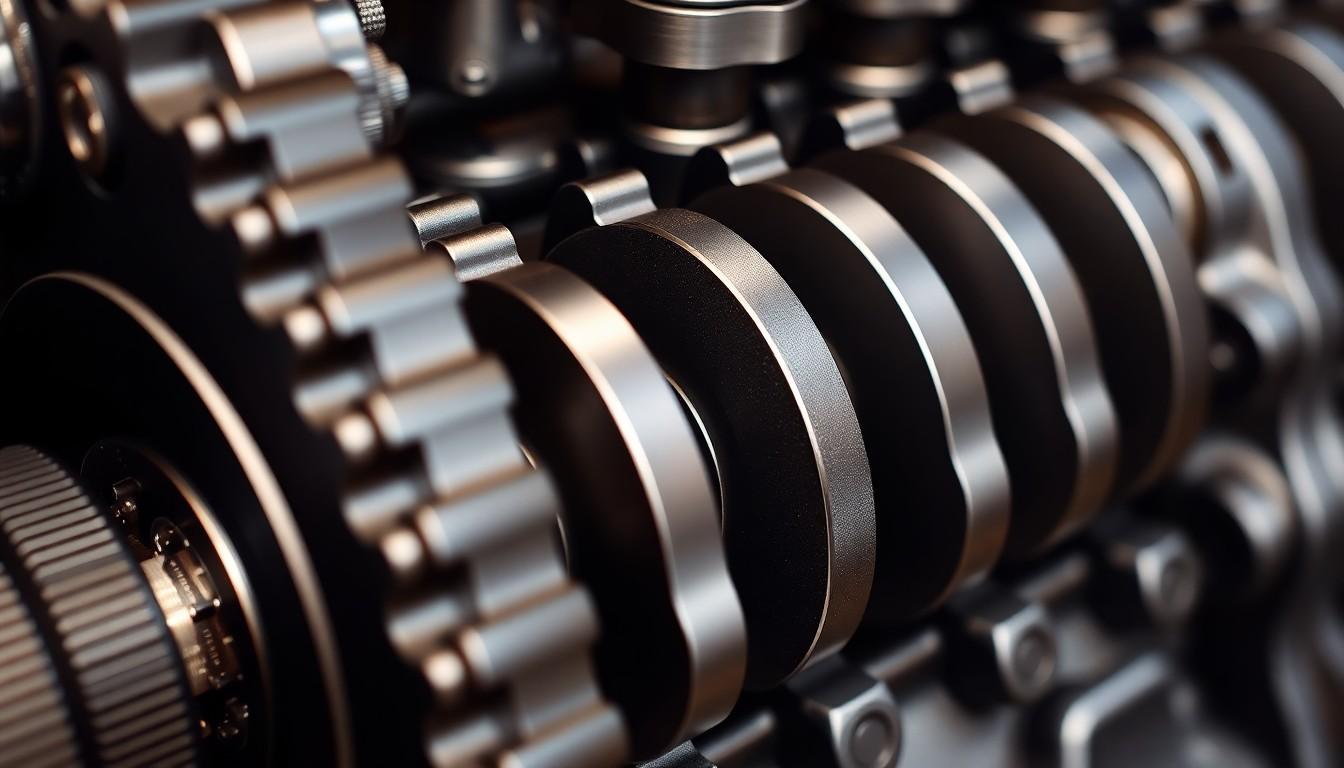

The Anatomy of a Flat Tappet Camshaft

The flat tappet camshaft’s distinctive design plays a crucial role in how an engine performs. Understanding its components and how they function together provides insight into why this type of camshaft remains popular in many engine applications.

Lifters and Tappets

Flat tappet lifters, even though their name, aren’t completely flat on their contact surface. They feature a slightly crowned face that works along with the camshaft lobe’s design. This crown creates a exact contact point that moves across the lobe as the camshaft rotates. The interaction between the lifter’s crown and the cam lobe’s taper generates a spinning motion in the lifter, distributing wear evenly across both surfaces rather than concentrating it in one spot.

Lobes and Their Design

Cam lobes on flat tappet camshafts incorporate a carefully engineered taper that’s essential for proper operation. This taper causes the lifter to rotate slightly with each cycle, preventing uneven wear patterns that could lead to premature failure. The lobe’s profile determines valve lift height, duration, and timing—all critical factors that affect engine performance characteristics. Each lobe’s precise shape controls exactly when valves open and close relative to piston position, making the design of these components a sophisticated balance of engineering considerations.

Material Composition

Flat tappet lifters are typically manufactured from hardened or chilled iron, making them more cost-effective than their roller counterpart alternatives. This material selection offers a good balance between durability and manufacturing simplicity. The camshaft itself is usually constructed from cast iron or steel alloys that provide the necessary hardness to withstand the constant friction from the lifters. These material choices contribute to the flat tappet cam’s reputation as an affordable option for many engine builders while still delivering reliable performance when properly lubricated and maintained.

How Flat Tappet Cams Work in an Engine

Flat tappet cams convert rotary motion into the reciprocating action needed to operate an engine’s valves. This mechanical relationship is fundamental to internal combustion engines and has been reliably employed for generations of automotive applications.

The Valve Train Operation

The valve train system relies on flat tappet cams to transform the camshaft’s rotational movement into linear motion that controls valve timing. As the camshaft rotates, each lobe pushes against its corresponding flat tappet, forcing it upward in a precise sequence. This vertical movement transfers through pushrods (in pushrod engines) or directly (in overhead cam designs) to the rocker arms, which then open the intake and exhaust valves. The tappet’s flat surface slides across the cam lobe’s profile during operation, creating a exact lift pattern that determines how long valves remain open and how far they open—critical factors affecting engine breathing and performance characteristics.

Lifter Movement and Dynamics

Flat tappet lifters function as cylindrical steel components that ride vertically on the camshaft lobes, translating cam profiles into valve movement. Each lifter’s slightly crowned face creates a spinning motion when contacting the cam lobe, distributing wear evenly across both surfaces and extending component life. Friction between the flat tappet and cam lobe is higher than in roller cam designs, making proper lubrication with zinc-rich oils essential for longevity. Flat tappet cams offer unlimited acceleration potential but have velocity limitations that influence valve opening rates. The direct sliding contact between components creates a distinctive break-in pattern and wear signature that engine builders recognize as normal for these systems. Performance characteristics of flat tappet cams include predictable valve control and reliable operation, though they typically can’t match the aggressive valve opening rates possible with roller tappet designs.

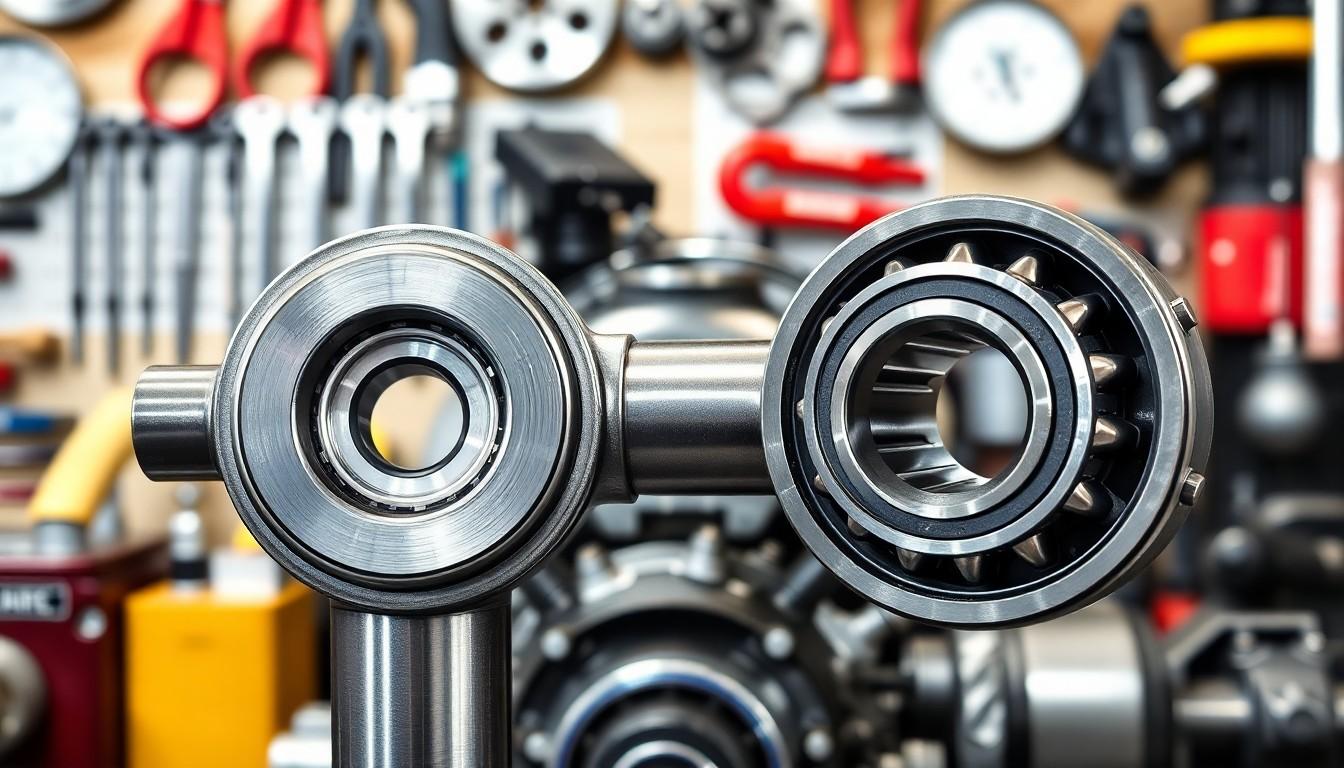

Flat Tappet vs. Roller Camshafts

Flat tappet and roller camshafts represent two distinct approaches to valve actuation in internal combustion engines. Each design offers exact advantages and limitations that impact engine performance, maintenance requirements, and overall cost considerations.

Performance Differences

Flat tappet cams perform admirably in many applications but don’t match the performance potential of roller designs. The primary limitation comes from their design constraints—flat tappet cams can’t use aggressive lobe profiles because the flat surface contact restricts how steeply the lobe can rise. Roller camshafts, in contrast, feature a wheel supported by needle bearings that significantly reduces friction and allows for much steeper cam lobes. This mechanical advantage translates to faster valve opening and longer duration of valve lift, eventually producing greater airflow and increased power output. High-performance applications benefit from roller cams’ ability to handle more aggressive profiles, making them the preferred choice for builders seeking maximum performance.

Durability Considerations

Flat tappet lifters experience more wear than roller designs due to their sliding contact with cam lobes. This scraping action creates friction that’s exacerbated by modern motor oils with reduced zinc content—an essential anti-wear additive for flat tappet systems. Engine builders typically replace flat tappet lifters when changing cams to ensure proper break-in and prevent premature failure. Roller lifters offer superior durability thanks to their rolling action that minimizes friction between components. This reduced wear extends the lifespan of both the lifters and cam lobes, often allowing roller lifters to be reused during camshaft changes. Even though their higher initial cost, roller camshafts frequently prove more cost-effective long-term due to their durability and reduced maintenance requirements.

Common Applications for Flat Tappet Cams

Flat tappet cams serve exact roles in the automotive industry, appearing predominantly in certain types of engines and build styles. Their design characteristics make them particularly suited for applications where tradition, cost-effectiveness, and exact performance attributes are valued.

Vintage and Classic Engines

Flat tappet camshafts dominated the engine industry in vehicles manufactured before the 1990s. These components were the standard in classic American muscle cars, vintage European sports cars, and nearly all production vehicles from earlier eras. Their widespread use stemmed from simpler manufacturing processes and lower production costs compared to roller cam alternatives. Many restoration projects maintain period correctness by using flat tappet cams that match the original specifications. Enthusiasts restoring classic vehicles often prefer these cams to preserve the authentic character and performance feel of vintage engines.

Budget Performance Builds

Cost-conscious engine builders frequently choose flat tappet cams when upgrading performance on a limited budget. These cams typically cost significantly less than their roller counterparts while still offering substantial performance gains. Even though their affordability, flat tappet cams can deliver comparable lifespans to roller designs when paired with proper maintenance and appropriate oil formulations containing zinc additives. Performance characteristics of flat tappet designs include excellent acceleration capabilities off the base circle, making them responsive in moderate performance applications. Custom grinds for flat tappet cams let builders achieve exact power curves customized to their driving needs without the premium price of roller technology.

Maintenance and Break-In Procedures

Proper maintenance and break-in procedures are essential for maximizing the lifespan and performance of flat tappet camshafts. These processes establish the foundation for long-term reliability and help prevent premature wear that can lead to engine failure.

Proper Oil Selection

Oil selection remains one of the most critical factors for flat tappet cam survival. Modern motor oils have reduced levels of zinc and phosphorus (ZDDP) additives that flat tappet cams rely on for proper lubrication at the cam-lifter interface. Engine oils specifically formulated for flat tappet applications contain higher concentrations of these anti-wear compounds. Performance oil manufacturers offer specialty oils with ZDDP levels exceeding 1,200 ppm, providing optimal protection during both break-in and regular operation.

Adding ZDDP supplements to conventional oils offers an alternative solution for engines with flat tappet cams. These additives restore the protective properties that modern low-ZDDP oils lack. Oil viscosity also plays a important role—most engine builders recommend 10W-30 or 15W-40 for break-in periods, transitioning to manufacturer-recommended viscosities for normal operation.

Regular oil changes at 3,000-mile intervals extend cam and lifter life by removing metal particles and contaminants that accelerate wear. This maintenance schedule proves especially important in performance applications where higher RPMs create additional stress on the valve train components.

Break-In Techniques

Break-in procedures create a crucial wear pattern between the cam lobes and lifters that determines overall camshaft longevity. The initial 20-30 minutes of operation establish this pattern through controlled metal transfer between components. Engines with flat tappet cams require exact break-in procedures that differ significantly from roller cam applications.

The correct break-in sequence starts with priming the oil system before initial startup, ensuring all components receive lubrication before the first rotation. Using a dedicated break-in oil with high ZDDP content provides essential protection during this critical phase. Engine speed variation between 1,500-2,500 RPM for the first 30 minutes prevents glazing and promotes proper mating of the cam and lifter surfaces.

Avoiding extended idle periods during break-in prevents inadequate lubrication at the cam-lifter interface. Varying engine speeds creates a ever-changing environment that encourages proper wear patterns while preventing localized heat buildup. After completing the initial break-in period, changing the oil and filter removes any metal particles generated during the process.

Many performance camshaft manufacturers include exact break-in instructions customized to their products, with variations depending on compression ratio, engine displacement, and valve spring pressure. Following these manufacturer-exact guidelines maximizes the potential for successful installation and long service life of your flat tappet camshaft system.

Conclusion

Flat tappet cams have stood the test of time as reliable components in engine design. While they may not offer the performance extremes of roller cams they deliver dependable operation and authentic character for vintage applications.

We’ve seen how their unique design creates that distinctive valve train operation enthusiasts appreciate in classic engines. With proper maintenance including zinc-rich oils and careful break-in procedures these workhorses continue to power countless vehicles.

Whether you’re restoring a classic car building a budget-friendly performance engine or simply expanding your automotive knowledge understanding flat tappet cams gives you valuable insight into fundamental engine operation. Their enduring presence in the automotive industry is a testament to their practical engineering and continued relevance.

Frequently Asked Questions

What is a flat tappet camshaft?

A flat tappet camshaft is a traditional engine component where the lifter (or tappet) has a flat face that contacts the cam lobe. This design has been used in internal combustion engines for over a century. Unlike roller cams, flat tappet designs rely on a sliding contact interface that requires proper lubrication and creates specific wear patterns. They come in two configurations: solid (mechanical) and hydraulic, each offering different performance characteristics.

How does a flat tappet camshaft work?

A flat tappet camshaft converts rotary motion into reciprocating action to operate engine valves. As the camshaft rotates, the shaped lobes push against the flat-faced lifters, which then transfer this motion to pushrods and rocker arms, ultimately opening and closing the valves. The slightly crowned face of the lifter interacts with the cam lobe’s taper to create a spinning motion that distributes wear evenly across the lifter surface.

What’s the difference between flat tappet and roller camshafts?

Flat tappet camshafts use a sliding contact between the lifter and cam lobe, while roller camshafts feature a wheel supported by needle bearings. Roller cams reduce friction, allow for steeper lobe profiles, and enable faster valve opening for increased power. Though flat tappet designs perform well, they have design constraints that limit aggressive profiles. Roller camshafts offer superior durability but come at a higher initial cost.

Why would someone choose a flat tappet cam over a roller cam?

People choose flat tappet cams for several reasons: they’re more budget-friendly, making them ideal for cost-conscious engine builds; they maintain period correctness in vintage and classic engines (pre-1990s); and they offer simplicity in design and installation. Despite their affordability, flat tappet cams can deliver substantial performance gains when properly maintained and are particularly popular in classic muscle cars and vintage trucks.

What oil should I use with a flat tappet camshaft?

Use oils with high levels of zinc and phosphorus (ZDDP) additives, which are essential for flat tappet cam lubrication. Since modern motor oils often lack sufficient ZDDP, choose specialty oils formulated for classic or high-performance engines. Alternatively, add ZDDP supplements to conventional oils. This proper lubrication is critical because flat tappet designs experience more friction than roller cams and require these anti-wear additives.

How do I break in a new flat tappet camshaft?

Break in a flat tappet camshaft by first priming the oil system and using dedicated break-in oil with high ZDDP content. Upon initial startup, vary the engine speed between 1,500-2,500 RPM for 20-30 minutes to promote proper mating between cam lobes and lifters. Avoid idling or high RPMs during this period. Follow manufacturer-specific instructions, as the break-in process establishes crucial wear patterns that determine longevity.

Can flat tappet cams be used in modern engines?

While flat tappet cams can technically be installed in many modern engines, they’re less common in newer designs that came factory-equipped with roller camshafts. Converting a modern engine to a flat tappet design is generally impractical and offers no performance advantage. However, flat tappet cams remain viable options for older engine platforms, especially in restoration projects or budget-conscious builds focusing on moderate performance gains.

How long do flat tappet camshafts typically last?

With proper maintenance, flat tappet camshafts can last 50,000-100,000 miles in street applications. Their lifespan depends greatly on adequate lubrication, correct break-in procedures, and regular oil changes with appropriate ZDDP additives. While they experience more wear than roller camshafts due to their sliding contact design, a well-maintained flat tappet cam in a street-driven vehicle can provide reliable service for many years.