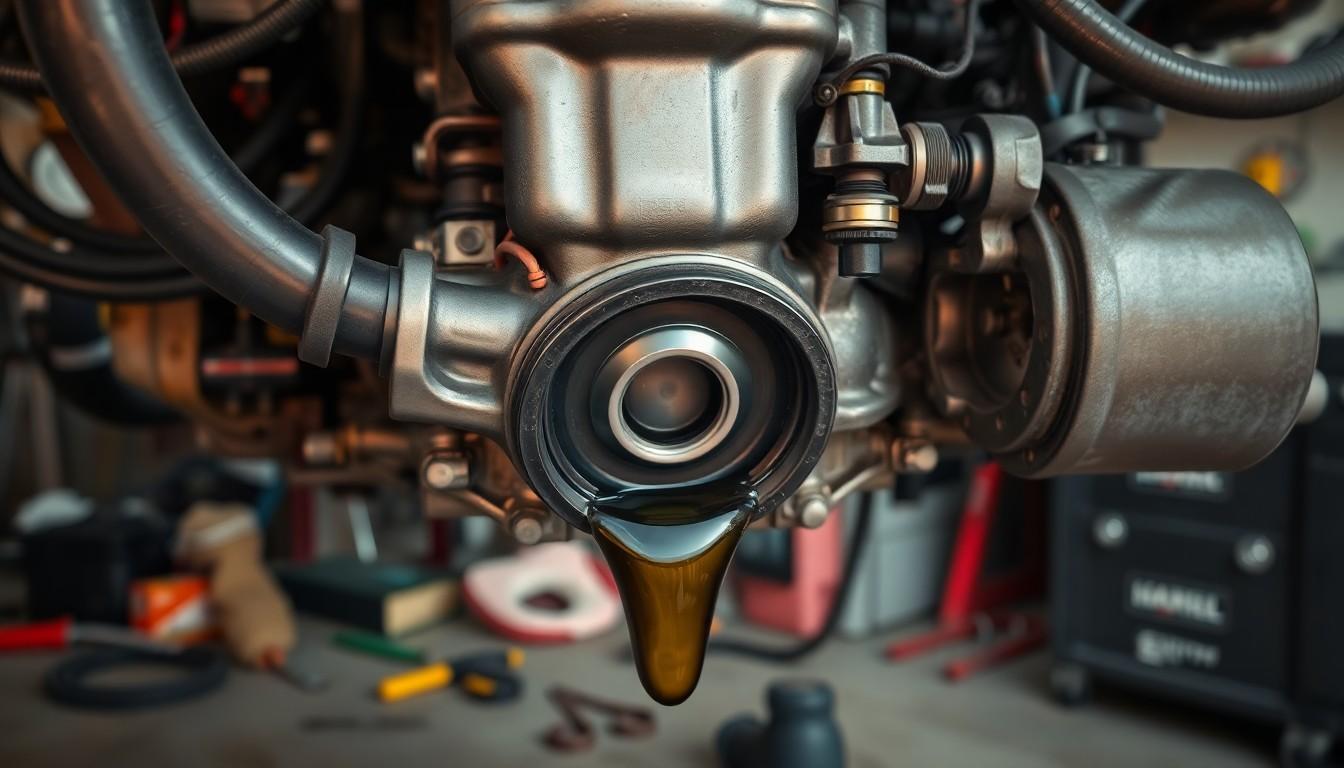

Ever noticed a mysterious puddle of oil beneath your parked vehicle? That telltale sign might point to a failing rear main seal. This critical component sits between your engine and transmission, preventing oil from leaking where these two major systems meet.

We’ve seen countless drivers puzzled by persistent oil leaks even though replacing gaskets and other seals. That’s because the rear main seal plays a unique role in your engine’s operation, and when it fails, the consequences can be both messy and expensive. Understanding this often-overlooked part can save you from unexpected repairs and keep your vehicle running smoothly for years to come.

What Is a Rear Main Seal?

A rear main seal is a critical engine component that prevents oil from leaking out where the crankshaft exits the back of the engine to connect with the transmission. Located at the junction between the engine block and transmission housing, this seal creates a crucial barrier against oil seepage. Most rear main seals are made of synthetic rubber or silicone compounds designed to withstand extreme temperatures and constant friction.

The seal fits snugly around the crankshaft’s rear main bearing, forming a tight connection that keeps engine oil contained within the crankcase. Modern vehicles typically use one-piece molded seals, while older engines often feature two-piece designs split at the crankshaft’s main bearing cap. Due to its location deep within the powertrain, accessing the rear main seal requires important disassembly, including removing the transmission and sometimes the engine itself.

When functioning properly, this seal allows the crankshaft to rotate freely while maintaining an oil-tight environment. The constant exposure to heat cycles, pressure changes, and friction eventually causes the seal material to harden and lose elasticity, leading to the common problem of rear main seal leaks seen in higher-mileage vehicles.

Location and Function of the Rear Main Seal

The rear main seal sits at the rear side of the engine where the crankshaft connects to the transmission. This strategic positioning creates a critical barrier between the crankshaft and the engine block or transmission bellhousing.

How It Seals Engine Oil

Rear main seals are typically constructed from rubber or silicone materials specifically designed to create a tight seal around the rotating crankshaft. These seals maintain constant pressure against the crankshaft surface, preventing engine oil from escaping through the gap between the crankshaft and engine block. By forming an effective barrier, the seal ensures oil remains contained within the engine’s lubrication system. Engine pressure and heat constantly challenge the seal’s integrity, making its durability crucial for maintaining proper engine operation. The seal’s flexible properties allow it to maintain contact with the crankshaft even though engine vibrations and temperature fluctuations.

Importance in the Drivetrain System

Rear main seals play a fundamental role in maintaining drivetrain integrity through several critical functions. First, they ensure proper oil retention within the engine, which directly affects the lubrication of the crankshaft, main bearings, and other moving components. Effective oil containment prevents premature wear on these expensive drivetrain components, extending engine life significantly. The seal also protects the transmission from potential oil contamination that could damage clutch plates in manual transmissions or torque converters in automatic transmissions. Even though their small size, rear main seals prevent catastrophic damage that oil starvation could cause to bearings and other precision-machined surfaces. Replacing this component often requires substantial labor, including transmission removal, making preventative maintenance particularly valuable for avoiding unexpected drivetrain failures.

Common Materials Used in Rear Main Seals

Rear main seals are manufactured from several exact materials, each offering unique properties that affect performance and longevity. The material selection directly impacts how well the seal prevents oil leakage and how long it lasts under harsh engine conditions.

Rubber Seals

Molded synthetic rubber ranks as the most prevalent material for modern rear main seals. It provides excellent sealing capabilities while resisting heat degradation, making installation relatively straightforward for mechanics. Nitrile rubber appears primarily in older vehicle applications, earning recognition for its impressive durability and resistance to both oil and fuel contamination. These rubber-based options deliver consistent performance across various engine types and operating conditions.

Silicone Seals

Silicone materials excel in high-temperature environments where standard rubber might fail. Even though their superior heat resistance, silicone seals tend to be more fragile compared to their rubber counterparts. Engine builders select silicone specifically for applications where extreme heat resistance takes priority over long-term durability, such as in certain high-performance engines that operate at elevated temperatures.

Other Materials

Polyacrylate seals offer a balanced combination of heat resistance and abrasion protection, making them suitable for moderate to heavy-duty applications. Viton® provides exceptional heat and abrasion resistance properties, establishing it as an ideal choice for demanding engine conditions or performance applications. PTFE (Polytetrafluoroethylene) rubber represents one of the most advanced materials currently available, though it requires dry installation to create a proper seal—any moisture or oil during installation compromises its effectiveness.

Rubber vs. Silicone Seals

Rubber seals demonstrate greater durability against the constant rotational forces generated by the crankshaft. Synthetic rubber variants install easily and resist heat effectively, making them the standard choice for most vehicle applications. Their primary limitation appears when engines operate at extremely high temperatures for extended periods.

Silicone seals shine in high-temperature resistance scenarios, benefiting high-performance or extremely hot-running engine environments. But, their increased fragility and reduced durability compared to rubber seals often leads to shorter lifespans and higher failure rates. This tradeoff between heat resistance and durability requires careful consideration when selecting replacement seals based on exact engine requirements and operating conditions.

Signs of a Failing Rear Main Seal

Detecting issues with your rear main seal early can save you from costly repairs and potential engine damage. Several telltale symptoms indicate when this critical component is beginning to fail.

Oil Leaks and Their Patterns

Oil leaks from a failing rear main seal appear in exact locations that distinguish them from other engine leaks. These leaks typically manifest at the rear side of the engine where it connects to the transmission. You’ll often notice oil puddles collecting directly under this junction point on your driveway or garage floor. The oil may also drip down or accumulate on the oil pan, creating a distinctive staining pattern that extends from the rear of the engine. Unlike valve cover leaks that appear higher on the engine, rear main seal leaks are concentrated at the transmission-engine connection point. Checking for oil residue in this exact area provides a strong indication of rear main seal failure.

Performance Issues Related to Seal Failure

A deteriorating rear main seal creates several performance problems beyond just oil leakage. Engine damage occurs when continuous oil loss leads to reduced oil pressure, compromising lubrication to critical components. Transmission issues frequently develop, especially in manual transmission vehicles where oil can contaminate the clutch system, causing it to slip or grab unexpectedly during operation. Your vehicle’s oil light may illuminate more frequently as oil levels drop faster than normal, requiring constant oil top-offs. The overall engine performance gradually degrades as proper lubrication becomes compromised, resulting in rougher operation and potential overheating. Decreased oil pressure from seal leakage puts bearings and other precision components at risk of premature wear. These performance issues compound over time, making prompt diagnosis and repair essential for maintaining your vehicle’s reliability and preventing more extensive damage to the drivetrain.

Rear Main Seal Replacement Process

Replacing a rear main seal involves extensive disassembly of the engine and transmission components. This process requires careful attention to detail and exact mechanical expertise to ensure proper installation and prevent future leaks.

DIY Replacement

The DIY approach to rear main seal replacement demands important mechanical knowledge and specialized tools. First, you’ll need to drain the engine oil completely before disconnecting and removing the transmission. After removing the flywheel or flexplate, you can access the old seal which must be carefully extracted without damaging the surrounding surfaces. Installation of the new seal requires precise alignment to prevent future leaks. Many DIYers underestimate the complexity of this job, as improper installation can lead to immediate leaks or premature seal failure. Reassembly follows the reverse order, requiring careful attention to torque specifications for all components.

Professional Repair

Professional mechanics bring expertise and specialized equipment to rear main seal replacements. They’re equipped with the proper tools to efficiently disassemble and reassemble the drivetrain components. Professional technicians follow manufacturer-exact procedures that ensure proper seal installation and prevent damage to surrounding components. Most repair shops offer warranties on their work, providing peace of mind that isn’t available with DIY repairs. Though more expensive than doing it yourself, professional installation often proves more cost-effective long-term by avoiding repeated repairs due to improper installation.

DIY vs. Professional Repair Considerations

DIY Advantages:

- Cost savings on labor (potentially $500-$2,000)

- Personal satisfaction from completing a challenging repair

- No need to schedule service appointments or arrange alternative transportation

DIY Disadvantages:

- High risk of improper installation leading to continued leaks

- Requires specialized tools that may be expensive to purchase

- Time-consuming process (often 8-15 hours for inexperienced mechanics)

- No warranty protection if errors occur

Professional Advantages:

- Expertise ensures proper installation the first time

- Access to specialized tools and equipment

- Warranty protection on parts and labor

- Faster completion time

- Potential to identify related issues during repair

Professional Disadvantages:

- Significantly higher total cost due to labor charges

- Vehicle downtime while waiting for service appointment

- Reliance on the shop’s schedule for repairs

Typical Replacement Costs

The financial investment for rear main seal replacement varies significantly depending on vehicle make, model, and repair location.

| Cost Factor | DIY Range | Professional Range |

|---|---|---|

| Parts Cost | $20-$100 | $20-$100 |

| Labor Cost | $0 | $500-$2,000+ |

| Tools | $50-$300+ | Included |

| Total Cost | $70-$400+ | $520-$2,100+ |

European and luxury vehicles typically fall at the higher end of the cost spectrum, while domestic and Asian vehicles often cost less to repair. Four-wheel drive vehicles and those with complex drivetrain configurations generally require more labor time, increasing overall costs. Some specialized engines may require additional parts replacement during the process, further affecting the final price. Location also impacts repair costs, with urban areas and dealerships typically charging premium rates compared to independent shops in rural areas.

Preventing Rear Main Seal Damage

Extending the life of your rear main seal requires proactive maintenance. Implementing several preventive measures can help you avoid the costly and labor-intensive process of rear main seal replacement.

Regular Oil Changes

Regular oil changes significantly reduce wear on the rear main seal and other engine components. Fresh oil maintains proper lubrication properties, preventing the oil from breaking down and becoming abrasive to seal materials. Adhering to your vehicle manufacturer’s recommended oil change intervals keeps contaminants from accumulating and causing premature seal deterioration.

Using the Right Oil

The viscosity of your engine oil directly impacts rear main seal performance. Switching to a heavier oil, such as 10W30 instead of 5W20, can provide better sealing capabilities in older engines with worn seals. Using manufacturer-recommended oil types ensures optimal performance and helps maintain the seal’s elasticity and sealing properties over time.

Avoiding Extreme Conditions

Environmental factors play a crucial role in seal longevity. Road salt, extreme temperatures, and corrosive substances accelerate the deterioration of rubber and silicone seals. Parking your vehicle in covered areas when possible protects the engine components from harsh weather conditions. Regular undercarriage cleaning, especially in winter months, removes corrosive substances that could damage the seal.

Monitoring for Leaks

Early detection of minor leaks can prevent catastrophic failures. Checking the area where the engine meets the transmission for oil spots or stains should become part of your regular vehicle inspection routine. Small leaks often indicate the beginning stages of seal deterioration, allowing you to address the issue before it requires complete transmission removal and major repair work.

Using Oil Additives

Oil additives designed specifically for seal restoration can temporarily resolve minor leaks. These products work by slightly expanding and softening hardened seals to improve their sealing capability. While not a permanent solution for severely damaged seals, additives can extend the service life of a seal that’s beginning to show signs of wear, potentially postponing an expensive replacement procedure.

Conclusion

The rear main seal may be small but its impact on your engine’s health is enormous. By recognizing early warning signs and taking preventive measures you’ll save thousands in potential repairs. Whether you choose DIY replacement or professional service understanding this critical component helps you make informed decisions about your vehicle’s maintenance.

Regular inspections and proper oil maintenance will extend your seal’s lifespan significantly. When problems do arise don’t delay addressing them – what starts as a small leak can quickly escalate to major engine damage. We’ve seen how this humble seal plays a crucial role in keeping your engine running smoothly for years to come.

Frequently Asked Questions

What is a rear main seal and why is it important?

A rear main seal is a critical engine component located at the junction between the engine block and transmission housing. It creates a barrier against oil seepage by fitting snugly around the crankshaft’s rear main bearing. This seal is vital because it prevents oil leaks, ensures proper engine lubrication, and protects the drivetrain from oil contamination, ultimately preventing expensive damage.

What are the signs of a failing rear main seal?

Signs include oil puddles or stains on the ground beneath the rear of the engine, oil on the bottom of the bell housing, reduced oil pressure, compromised engine performance, and potential transmission issues (especially in manual vehicles). Early detection is crucial as these problems worsen over time and can lead to extensive drivetrain damage if left unaddressed.

What materials are rear main seals made from?

Rear main seals are typically made from synthetic rubber, nitrile rubber, silicone, polyacrylate, Viton®, or PTFE. Rubber seals offer excellent sealing capabilities and durability against rotational forces. Silicone seals perform better in high-temperature environments but may have shorter lifespans. The material choice affects performance and longevity under specific engine conditions.

How much does it cost to replace a rear main seal?

Replacement costs vary significantly based on vehicle make, model, and repair location. Labor typically ranges from $500-$1,800 because the process requires extensive disassembly. European and luxury vehicles cost more to repair than domestic and Asian models. The part itself is relatively inexpensive ($20-$100), but labor makes up the bulk of the expense.

Can I replace a rear main seal myself?

While DIY replacement is possible, it requires extensive mechanical knowledge and specialized tools. The process involves removing the transmission or engine, which is labor-intensive and risky for inexperienced mechanics. Improper installation can cause immediate leaks and engine damage. For most drivers, professional replacement is recommended despite the higher cost.

How can I extend the life of my rear main seal?

Perform regular oil changes with the manufacturer-recommended oil viscosity to reduce wear. Avoid extended periods of high RPM driving and extreme temperature conditions. Monitor for early signs of leaks during routine maintenance. Consider using oil additives designed for seal restoration to address minor leaks temporarily. Proper maintenance helps avoid the costly replacement process.

How long does a rear main seal typically last?

A rear main seal can last between 80,000 to 100,000 miles under normal driving conditions. However, this varies based on driving habits, maintenance practices, and environmental factors. Some seals may fail earlier due to heat exposure, pressure changes, or oil quality issues, while others can last the lifetime of the vehicle with proper care.

Will a leaking rear main seal cause engine damage?

Yes, a leaking rear main seal can eventually cause significant engine damage. Continuous oil loss leads to decreased oil pressure, inadequate lubrication, increased friction between moving parts, and potential overheating. If severe enough, it can result in bearing failure, crankshaft damage, and catastrophic engine failure that requires complete rebuilding or replacement.