Wondering what makes your car’s engine run so smoothly? The camshaft is one of those unsung heroes working tirelessly under your hood. This critical component controls the timing of your engine’s valves, orchestrating the precise dance of air and fuel that powers your vehicle forward.

We’ll demystify this essential engine part and explain why it matters to every driver. Whether you’re troubleshooting engine issues or simply expanding your automotive knowledge, understanding the camshaft’s role can help you make better maintenance decisions and appreciate the engineering marvel that propels you down the road.

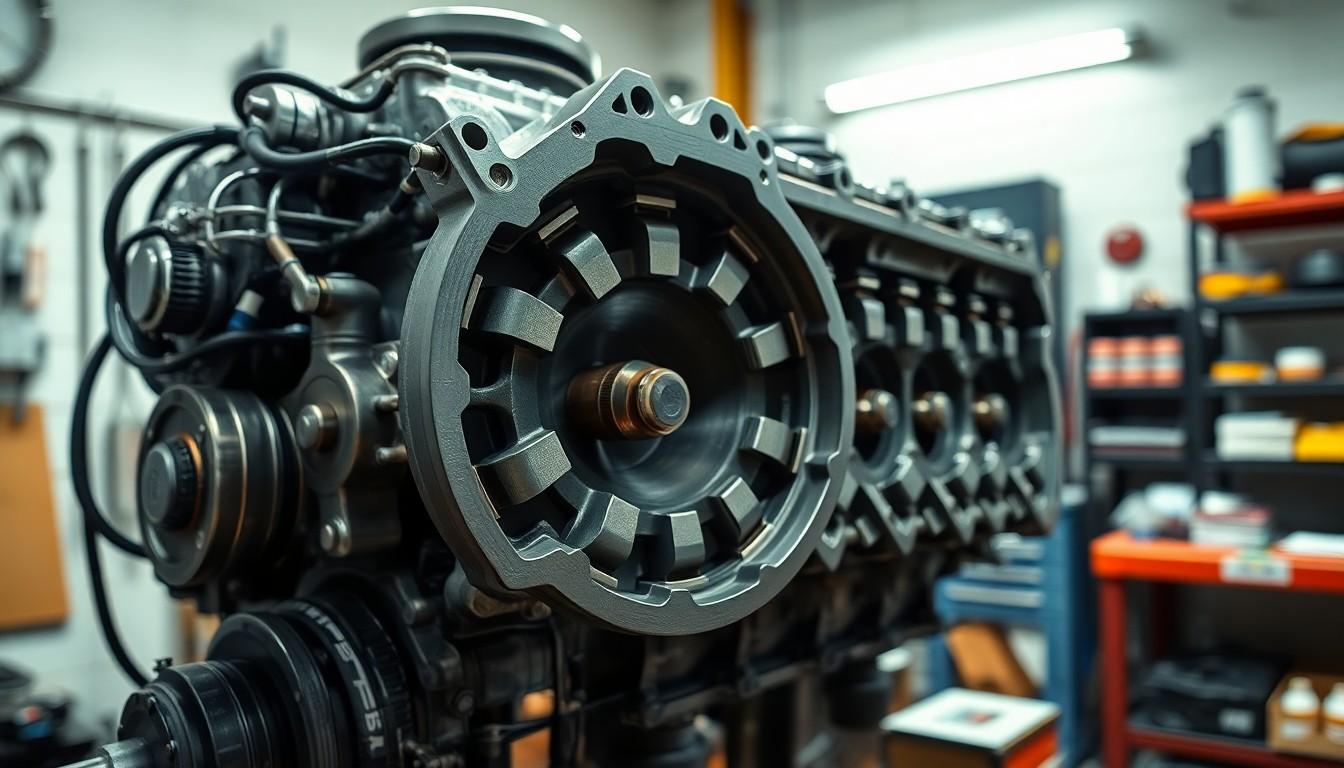

What Is a Camshaft in an Engine?

A camshaft is a rotating cylindrical shaft in an internal combustion engine that converts rotational motion into reciprocating motion to operate the intake and exhaust valves. Located either in the cylinder head (overhead camshaft) or in the engine block (cam-in-block design), this critical component features egg-shaped lobes called cams that push against valve lifters as the shaft rotates. Each cam’s precise shape determines when valves open and close during the combustion cycle, directly affecting engine performance, power output, and efficiency.

Camshafts work by rotating in synchronization with the crankshaft, typically at half the crankshaft speed in four-stroke engines. The lobes on the camshaft press against followers, pushrods, or directly on valve stems, transforming the shaft’s rotational movement into the up-and-down motion needed to open and close valves at precisely timed intervals. This timing controls when fresh air-fuel mixture enters the combustion chamber and when exhaust gases exit, making the camshaft essential to the engine’s breathing process.

Different engines employ various camshaft configurations to achieve exact performance objectives. Modern vehicles commonly use single overhead camshaft (SOHC) designs that operate both intake and exhaust valves, or dual overhead camshaft (DOHC) systems with separate shafts for intake and exhaust valves. Performance engines often feature aggressive cam profiles with higher lift and longer duration to enhance power at higher RPMs, while economy-focused engines use milder profiles that prioritize low-end torque and fuel efficiency.

The Function and Purpose of a Camshaft

A camshaft serves as the critical timing component in an internal combustion engine, orchestrating the precise opening and closing of intake and exhaust valves. This cylindrical rod with egg-shaped lobes (cams) regulates when fuel and air enter the combustion chamber and when exhaust gases exit, directly impacting engine performance and efficiency.

How a Camshaft Controls Valve Timing

The camshaft converts rotational motion into linear motion through its unique design. As it rotates, each cam pushes against valve lifters or directly on valve stems, creating the up-and-down movement needed to open and close the valves at exactly the right moments in the combustion cycle. The exact shape and positioning of each lobe determines exactly when a valve opens, how long it stays open, and when it closes—all critical factors in the engine’s breathing process. Timing accuracy within milliseconds ensures that the air-fuel mixture enters the cylinder during the intake stroke and exhaust gases exit during the exhaust stroke, maintaining the engine’s optimal operation sequence.

The Relationship Between Camshafts and Engine Performance

Camshaft design significantly influences a vehicle’s overall performance characteristics, affecting horsepower, torque, fuel efficiency, and emissions. Engines with aggressive cam profiles typically deliver more power at higher RPMs by keeping valves open longer, allowing more air and fuel into the combustion chambers. Economy-focused engines use milder cam profiles that prioritize low-end torque and fuel efficiency over maximum power output. Modern vehicles often use variable valve timing (VVT) systems that can adjust camshaft positions on the fly, optimizing performance across different driving conditions. Dual overhead camshaft (DOHC) configurations provide more precise valve control than single overhead camshaft designs, enabling better breathing at higher engine speeds and contributing to improved performance in high-output engines.

Types of Camshafts in Modern Engines

Modern engines use different camshaft configurations, each designed to achieve exact performance characteristics and efficiency goals. These configurations primarily include overhead camshafts and dual overhead camshafts, which have become standard in contemporary vehicle designs.

Overhead Camshafts (OHC)

Overhead Camshaft (OHC) systems position the camshaft directly in the cylinder head above the valves. This strategic placement simplifies the valve train mechanism and reduces the distance between cam lobes and valves, creating a more efficient valve actuation process. OHC engines typically feature one camshaft per bank of cylinders in V-type engines or a single camshaft for inline engines. The reduced weight and complexity of this design contribute to better fuel economy and performance compared to older cam-in-block designs. Many manufacturers prefer OHC configurations because they allow for more compact engine designs while maintaining reliable valve control.

Dual Overhead Camshafts (DOHC)

Dual Overhead Camshafts (DOHC) represent an advanced configuration featuring two separate camshafts per cylinder bank. One camshaft exclusively controls the intake valves while the other manages the exhaust valves, enabling precise and independent control over valve timing and lift. DOHC systems are particularly common in high-performance and modern four-cylinder inline engines, boxer engines, and V-type engines. The dedicated control offered by this setup allows engines to breathe more efficiently, especially at higher RPMs, resulting in improved power output and throttle response. Each bank of cylinders in V-configuration engines typically has its own pair of camshafts, optimizing valve operation throughout the entire power band.

Camshaft Construction and Materials

Camshafts are typically designed as cylindrical rods with multiple protruding cam lobes positioned strategically along their length. Each cam lobe corresponds to a exact valve that it operates within the engine. The precise design and placement of these lobes directly influence the valve timing and lift, affecting overall engine performance.

Design Features

Camshafts connect to the engine’s crankshaft through timing belts or chains that ensure synchronized operation. Modern engines predominantly use timing chains due to their durability and maintenance-free characteristics. These timing components maintain the crucial relationship between the crankshaft and camshaft rotation, preserving the exact valve timing necessary for proper combustion.

Materials Used

Cast iron serves as the primary material for most production camshafts due to its cost-effectiveness and suitable wear characteristics. Manufacturers enhance the durability of cast iron camshafts through a chilling process that creates a harder surface layer, improving resistance to the continuous friction encountered during operation.

Billet steel camshafts appear more frequently in high-performance applications or limited production engines. These premium camshafts offer superior strength and precision but come with significantly higher production costs. Performance enthusiasts often select billet steel camshafts when seeking maximum durability under extreme operating conditions.

Manufacturing Methods

Several manufacturing techniques produce camshafts with varying characteristics:

- Forging creates exceptionally strong camshafts by compressing heated metal under tremendous pressure

- Machining offers precise dimensional control by cutting away material from solid metal stock

- Casting provides cost-effective production by pouring molten metal into shaped molds

- Hydroforming utilizes high-pressure fluid to shape metal, creating complex profiles with consistent quality

Each manufacturing method presents different advantages about strength, precision, and production efficiency. The selected technique typically depends on the intended application and production volume requirements.

Common Camshaft Problems and Symptoms

Camshaft issues can significantly impact engine performance and longevity. Several common problems affect camshafts, each with distinct symptoms that indicate potential trouble. Let’s explore these issues to help you identify and address them before they cause serious engine damage.

Wear and Tear on Cam Lobes

Cam lobes gradually wear down over time, affecting the precise valve timing necessary for optimal engine function. This wear manifests through reduced engine performance, noticeably decreased power output, and poor fuel efficiency. As the lobes flatten or become misshapen, they can’t properly actuate the valves, leading to combustion inefficiencies and diminished overall engine responsiveness.

Bent or Damaged Camshaft

A bent or damaged camshaft disrupts the critical timing of valve operations, creating serious performance issues. The primary symptoms include engine misfires, rough idling, and decreased engine performance. These problems occur because the damaged camshaft can’t precisely control valve opening and closing sequences, resulting in improper air-fuel mixture and combustion timing.

Incorrect Installation or Alignment

Proper camshaft installation and alignment are crucial for engine functionality. When incorrectly installed or misaligned, camshafts cause poor engine performance, frequent misfires, and potential engine damage. The misalignment prevents proper synchronization with the crankshaft, throwing off the entire combustion cycle timing and potentially causing valves to contact pistons in some engines.

Worn or Faulty Lifters

Lifters serve as the interface between the camshaft and valves, making their condition critical to proper valve operation. Worn or faulty lifters typically produce noisy engine operation (often a distinctive tapping sound), reduced power output, and poor fuel efficiency. These components fail to follow the camshaft’s profile correctly, creating improper valve lift and duration that diminish engine performance.

Timing Belt or Chain Issues

The connection between the camshaft and crankshaft relies on a timing belt or chain. Problems with these components lead to engine misfires, poor performance, and potentially catastrophic engine failure. A broken or worn timing mechanism causes the camshaft to lose synchronization with the crankshaft, which can result in valves striking pistons and causing extensive internal engine damage in interference engines.

Camshaft Maintenance and Replacement

Importance of Maintenance

Proper maintenance of the camshaft ensures optimal engine performance, fuel efficiency, and overall engine health. Regular inspection prevents potential issues that could lead to decreased performance or engine failure. Wear on cam lobes directly impacts valve operation, reducing power output and efficiency over time. Engine longevity depends significantly on maintaining this critical component in good working condition.

Considerations for Replacement

When replacing or upgrading a camshaft, several critical factors must be addressed:

- Compatibility with existing engine components ensures proper function and prevents damage

- Rocker arms and valvetrain components must match the specifications of the new camshaft

- Adjustable cam gear often requires recalibration to maintain precise valve timing

- Engine RPM range should align with the camshaft profile for optimal performance

- Piston clearance must be verified to prevent mechanical interference

- Fuel management systems need to complement the camshaft’s profile for efficient operation

Each of these considerations plays a vital role in successful camshaft replacement. The interrelationship between these components creates a complex system that requires careful planning before any replacement occurs.

Steps for Replacement

Seeking expert guidance is essential when replacing or upgrading a camshaft. Professional mechanics understand the intricate relationships between engine components and can ensure proper installation. The timing belt requires thorough inspection and possible replacement to maintain synchronization between the crankshaft and camshaft.

All related components deserve careful attention during replacement:

- Valves should be inspected for wear patterns

- Valve seals might need replacement to prevent oil consumption

- Valve springs must match the camshaft’s specifications

- Lifters or followers often require replacement alongside the camshaft

This comprehensive approach to camshaft replacement prevents cascading failures in the engine’s valvetrain. Proper installation guarantees that the camshaft performs its critical function efficiently, maintaining the engine’s power output and longevity.

Conclusion

The camshaft stands as a marvel of automotive engineering that’s fundamental to your engine’s operation. By precisely controlling valve timing it orchestrates the complex dance of combustion that powers your vehicle.

Whether you drive a car with a traditional OHC system or a high-performance DOHC configuration the camshaft’s design directly impacts your driving experience through power delivery fuel efficiency and engine longevity.

Regular maintenance and proper attention to camshaft health aren’t just good practices—they’re essential for preventing costly repairs and ensuring optimal performance. We’ve seen how even small issues with this critical component can cascade into important engine problems.

Understanding your camshaft empowers you to make informed decisions about your vehicle’s care and appreciate the incredible engineering beneath your hood.

Frequently Asked Questions

What is a camshaft in a car engine?

A camshaft is a rotating cylindrical shaft in an internal combustion engine that converts rotational motion into reciprocating motion. It controls the opening and closing of intake and exhaust valves, regulating the air-fuel mixture that powers your vehicle. The camshaft features egg-shaped lobes (cams) that push against valve lifters to create the necessary valve movement during the combustion cycle.

Where is the camshaft located in the engine?

The camshaft can be located in one of two places: in the cylinder head (overhead camshaft design) or in the engine block (cam-in-block design). Modern vehicles typically use overhead camshaft configurations for better efficiency. The location affects how the camshaft interacts with the valves and influences the overall design and performance characteristics of the engine.

What’s the difference between SOHC and DOHC?

SOHC (Single Overhead Camshaft) uses one camshaft to operate both intake and exhaust valves, offering a simpler, more compact design. DOHC (Dual Overhead Camshaft) uses two separate camshafts—one for intake valves and one for exhaust valves. DOHC systems provide better valve control, improved airflow, and typically higher performance at higher RPMs, which is why they’re common in performance-oriented engines.

How does the camshaft affect engine performance?

The camshaft directly impacts engine performance through its lobe profile design. Aggressive cam profiles with higher lift and longer duration enhance power at higher RPMs but may sacrifice low-end torque. Milder profiles focus on fuel efficiency and low-end responsiveness. The timing of valve openings and closings determined by the camshaft affects combustion efficiency, power output, fuel economy, and emissions performance.

What are common symptoms of a bad camshaft?

Common symptoms include engine misfires, poor idle quality, reduced power output, decreased fuel efficiency, and unusual ticking or knocking noises from the engine. You might also experience rough running, stalling, illuminated check engine light, or failed emissions tests. In severe cases, a damaged camshaft can cause the engine to not start at all or result in catastrophic engine failure.

How long do camshafts typically last?

With proper maintenance, camshafts can last the lifetime of the engine—often 150,000 to 200,000 miles or more. However, their longevity depends on several factors including engine design, maintenance practices, oil quality and change frequency, driving habits, and manufacturing quality. Premature failure can occur due to inadequate lubrication, contaminated oil, or issues with related components like lifters.

Can I replace a camshaft myself?

Replacing a camshaft is a complex job requiring specialized tools, technical knowledge, and considerable mechanical experience. The process involves disassembling much of the engine, ensuring precise timing during reinstallation, and potentially recalibrating adjustable cam gears. Most experts recommend leaving this job to professional mechanics or experienced engine builders to avoid potentially catastrophic engine damage.

What materials are camshafts made from?

Most production camshafts are made from cast iron, which is enhanced through a chilling process for durability. High-performance applications often use billet steel camshafts for superior strength and precision. Manufacturing methods include forging, machining, casting, and hydroforming, each offering different advantages in terms of strength, precision, and production efficiency depending on the intended application.

How does Variable Valve Timing (VVT) relate to camshafts?

Variable Valve Timing systems work with camshafts to optimize valve timing across different engine speeds and loads. VVT can advance or retard camshaft timing relative to the crankshaft position, improving power delivery, fuel efficiency, and emissions throughout the RPM range. This technology allows engines to perform well at both low and high speeds, essentially providing the benefits of different camshaft profiles in one engine.

How often should I inspect my camshaft?

Direct camshaft inspection isn’t part of routine maintenance as it requires significant engine disassembly. However, you should monitor for symptoms of camshaft issues and maintain regular oil changes with the manufacturer-recommended oil type. If your vehicle has a timing belt, follow the replacement interval (typically 60,000-100,000 miles) as this service provides an opportunity to inspect related components.