Ever wondered what keeps your car’s engine running smoothly? Engine valves are the unsung heroes working tirelessly beneath your hood. These small but mighty components control the flow of air and fuel into your engine’s combustion chambers and allow exhaust gases to escape at precisely the right moments.

We’ll jump into the intriguing area of engine valves and explain why they’re critical to your vehicle’s performance. From intake valves that welcome the perfect air-fuel mixture to exhaust valves that expel spent gases, these precision-engineered parts operate in perfect harmony thousands of times per minute. Without properly functioning valves, your engine would quickly overheat, lose power, or fail completely.

What Is an Engine Valve: The Heart of Your Engine’s Breathing System

Engine valves are precision-engineered components that control the flow of gases in and out of the combustion chamber. These mechanical marvels open and close thousands of times per minute, allowing fresh air-fuel mixture to enter while permitting burned exhaust gases to exit. Located in the cylinder head, valves create a tight seal against the valve seats when closed, maintaining proper compression and preventing leakage during the combustion process.

The design of engine valves varies based on exact engine requirements, but most feature a disk-shaped head connected to a long stem. Valve stems extend through valve guides that maintain proper alignment during operation, ensuring consistent contact with the valve seat. Most modern passenger vehicles use four valves per cylinder (two intake, two exhaust) to optimize airflow and enhance engine efficiency.

Materials used in valve construction include high-grade steel alloys, titanium, and inconel—each selected to withstand extreme operating temperatures and pressure conditions. Intake valves typically use nickel-chromium alloys since they operate at lower temperatures (around 800°F/427°C), while exhaust valves often contain higher percentages of nickel and chromium to withstand temperatures exceeding 1,400°F/760°C.

Engine valves don’t work alone—they’re part of a complex valvetrain system including valve springs, retainers, keepers, and various actuation mechanisms. Valve timing and lift are controlled by camshafts, which push directly on the valves or activate them through pushrods, rocker arms, or hydraulic lifters depending on the engine design. Advanced engines incorporate variable valve timing systems that adjust valve operation based on engine speed and load for optimized performance.

Types of Engine Valves and Their Functions

Engine valves play distinct roles in the combustion process, with each type designed for exact functions within the engine’s operation. Modern engines typically contain multiple valves working in precise coordination to maximize efficiency and performance.

Intake Valves

Intake valves control the flow of the air-fuel mixture into the combustion chambers. During the intake stroke, these valves open as the piston moves downward, creating a vacuum that draws the air-fuel mixture into the cylinder. Once the intake stroke completes, the valve closes tightly against its seat, allowing the mixture to be compressed and later ignited. Intake valves generally operate at lower temperatures than their exhaust counterparts since they’re continuously cooled by the incoming air-fuel mixture. Most contemporary engines feature two intake valves per cylinder to enhance airflow capacity and improve volumetric efficiency.

Exhaust Valves

Exhaust valves help the removal of burned gases from the combustion chambers after ignition. These valves open during the exhaust stroke as the piston moves upward, forcing the combustion gases out of the cylinder and into the exhaust system. Exhaust valves endure significantly higher temperatures than intake valves, often exceeding 1,400°F (760°C) during operation. This extreme heat exposure necessitates construction from highly heat-resistant materials like austenitic steel or special alloys. Many performance engines use hollow sodium-filled exhaust valves where liquid sodium inside the valve transfers heat from the valve head to the cooler stem, improving durability and preventing valve failure under demanding conditions.

How Engine Valves Work in the Combustion Process

Engine valves operate in perfect synchronization with multiple engine components to help the combustion process efficiently. The precise timing of valve opening and closing ensures optimal engine performance throughout all operating conditions.

Synchronization with Camshaft

The camshaft serves as the primary timing controller for engine valves, dictating exactly when they open and close. Pear-shaped lobes on the camshaft push the valves open at exact intervals and allow them to close when needed. This intricate timing mechanism ensures the engine operates efficiently regardless of speed variations. The camshaft’s rotation creates the rhythmic pattern of valve movement essential for proper combustion.

Operation Sequence

Engine valves follow a exact sequence during the four-stroke combustion cycle:

- Intake Stroke: Intake valves open as the piston moves downward, creating vacuum pressure that draws the air-fuel mixture into the cylinder

- Compression Stroke: Both intake and exhaust valves remain closed while the piston moves upward to compress the air-fuel mixture

- Power Stroke: Valves stay closed as the spark plug ignites the compressed mixture, forcing the piston downward and generating power

- Exhaust Stroke: Exhaust valves open while the piston moves upward again, expelling spent gases from the combustion chamber

This continuous cycle repeats thousands of times per minute in a running engine, with valves opening and closing with millisecond precision.

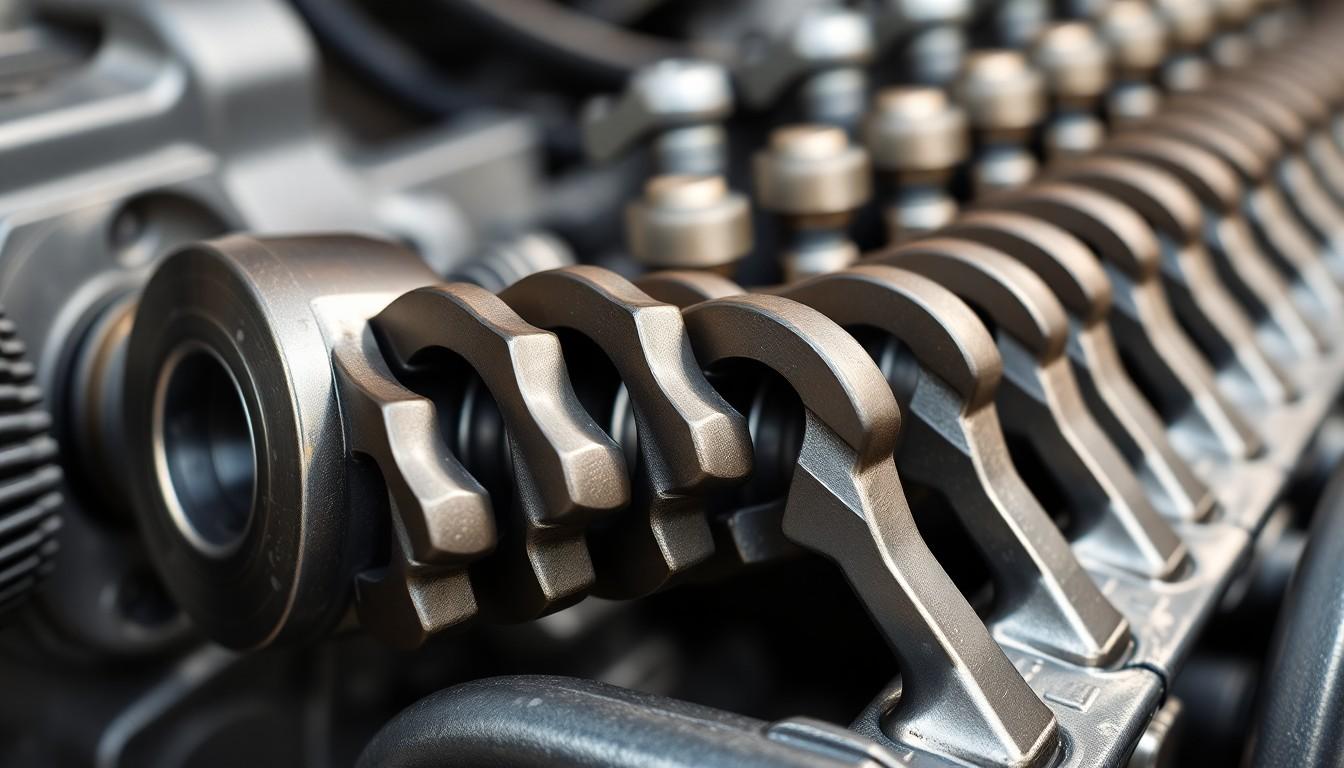

Interaction with Other Components

Engine valves work collaboratively with several other engine components to maintain proper operation. Rocker arms transfer motion from the camshaft to the valves, controlling their movement. Valve lifters (also called tappets) maintain the correct gap between the camshaft and valves, ensuring proper contact. Valve springs provide the return force necessary to close valves after they’ve been opened by the camshaft. This integrated system of components working together enables the precise valve timing required for efficient combustion.

Anatomy of an Engine Valve

Engine valves consist of several precisely engineered components that work together to control the flow of air, fuel, and exhaust gases. Each part serves a exact function in maintaining engine efficiency and performance.

Valve Head

The valve head forms the wide portion of the valve that creates a tight seal against combustion pressure. Its design includes a carefully engineered fillet that transitions into a seat face, machined at a exact angle to match the valve seat. This precise angle ensures a complete seal when the valve is closed, preventing compression loss or exhaust leakage. The valve head must withstand extreme temperatures and pressures while maintaining dimensional stability throughout thousands of cycles.

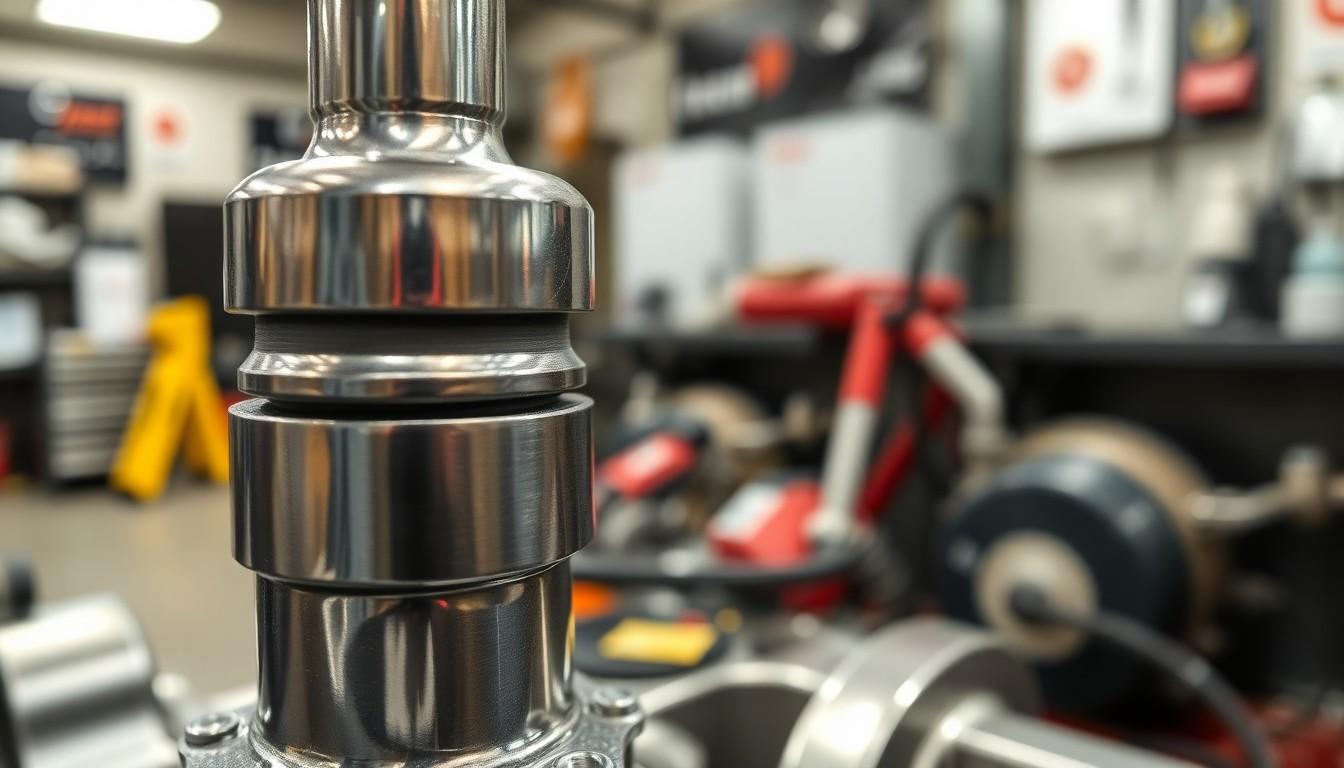

Valve Stem

Valve stems connect the valve head to the mechanical components that control its movement, such as rocker arms and camshafts. They transmit the force needed to lift the valve against spring pressure, allowing gases to flow through the engine as required. Stems are manufactured to precise tolerances to prevent binding in the valve guide while minimizing clearance that could lead to oil consumption. The length and diameter of valve stems vary depending on engine specifications and performance requirements.

Valve Seat

Valve seats provide the mating surface against which valve heads seal. These surfaces are machined into the cylinder head with exact angles to match the valve face, creating an airtight seal when closed. Premium valve seats often contain copper alloys or other heat-dissipating materials to draw thermal energy away from the valve head. Proper maintenance of valve seats is critical, as worn seats can cause compression loss, reduced power, and potential engine damage. The interface between the valve and seat must remain intact even though thousands of impact events per minute during normal engine operation.

Common Valve Materials and Construction

Engine valves require exceptional materials and construction techniques to withstand the extreme conditions inside combustion engines. The materials selected must provide optimal heat resistance, strength, and durability to ensure reliable engine performance.

Materials

Engine valves are manufactured from several high-performance materials:

- Stainless Steel delivers outstanding heat resistance and strength, making it a popular choice for many standard engine applications

- Titanium provides an exceptional strength-to-weight ratio combined with excellent heat resistance, often used in high-performance and racing engines

- Inconel Alloy offers superior heat resistance and corrosion protection, ideal for the most demanding operating environments

Construction

Engine valves are built using specialized construction methods to maximize performance and longevity:

- Monometallic Engine Valves feature a single material forming both the valve stem and head. These valves deliver high heat resistance and excellent anti-friction properties, perfectly suited for standard engine applications.

- Bimetallic Engine Valves combine two different metals—typically austenitic steel for the valve head and martensitic steel for the valve stem—joined through friction welding. This combination enhances durability and performance, particularly beneficial in high-performance or heavy-duty engines.

- Hollow Engine Valves represent specialized bimetallic valves containing a hollow cavity filled with sodium. The sodium liquefies at operating temperatures and circulates to transfer heat away from the valve head, significantly improving heat dissipation in modern high-performance engines experiencing elevated exhaust gas temperatures.

Precision machining and specialized surface treatments further enhance valve sealing capabilities and longevity in challenging operating conditions. Each valve’s design and construction are carefully customized to meet exact performance, efficiency, and durability requirements across various internal combustion engine applications.

Valve Train Components: The Supporting Cast

The valve train system consists of several crucial components that work together to ensure proper valve operation in internal combustion engines. These supporting parts maintain timing precision and protect against premature wear while enabling the valves to perform their critical functions.

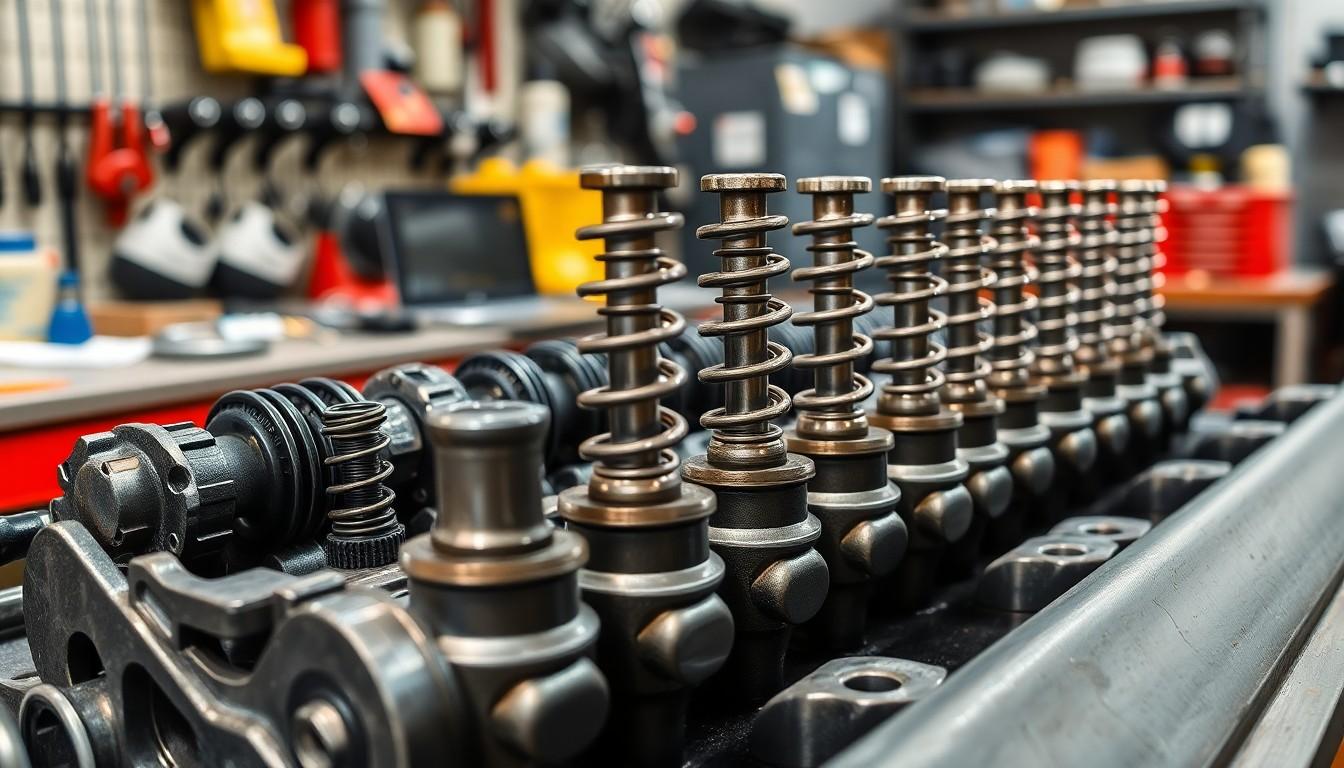

Valve Springs

Valve springs provide the essential force needed to close engine valves after the camshaft opens them. These helical components maintain proper valve timing by ensuring valves return to their seated position promptly after opening. Without functioning valve springs, engines experience valve float—a condition where valves don’t close completely at high RPMs, leading to power loss and potential engine damage. Valve springs create the necessary tension to keep valves properly sealed against their seats during compression and power strokes, maintaining critical combustion chamber pressure.

Valve Guides and Seals

Valve guides serve as precision-machined channels that direct valve stems during their up-and-down movement within the cylinder head. These cylindrical components maintain proper valve alignment, preventing lateral movement that could cause uneven wear or improper sealing. Valve guides effectively transfer heat away from valve stems, contributing to temperature regulation in these critical areas.

Valve seals, also known as valve stem seals, prevent oil from entering the combustion chamber through the small gap between the valve stem and guide. These rubber or synthetic components control oil consumption by limiting the amount of lubricant that reaches valve stems. Properly functioning valve seals reduce emissions, prevent blue exhaust smoke, and maintain optimal oil levels. Modern valve seals use specialized materials designed to withstand high temperatures and retain elasticity throughout thousands of operating hours.

Signs of Failing Valves and Maintenance Tips

Warning Signs of Valve Problems

Engine valves display several telltale symptoms when they begin to fail. Ticking or tapping noises from the engine often indicate valve clearance issues or damaged components. Performance degradation manifests as noticeable power loss during acceleration or when climbing hills. Starting problems might occur as faulty valves prevent proper compression or disrupt the air-fuel mixture. Fuel efficiency drops significantly when valves don’t seal correctly, allowing pressure to escape during combustion. Excessive smoke from the exhaust pipe, particularly blue or white smoke, signals that valves aren’t sealing properly against their seats.

Essential Valve Maintenance

Regular valve inspections form the cornerstone of proper engine maintenance. Checking valve seal integrity ensures clean combustion and prevents performance issues before they become serious. Valve adjustments require precise measurements of clearances between valve components, typically performed during major tune-ups. Timing synchronization matters immensely, as valves must open and close at exact moments controlled by the camshaft for optimal engine operation. Professional mechanics use specialized tools to verify these complex timing relationships during service intervals.

Professional Service Recommendations

Valve maintenance involves complex procedures best handled by qualified technicians. Professional inspection services typically include compression testing to identify leaking valves and visual examinations using borescopes to assess valve condition. Valve adjustment services involve setting proper clearances according to manufacturer specifications for your exact engine model. Complete valve replacements become necessary when valves show signs of burning, warping, or excessive wear that affects engine performance. Many mechanics recommend valve inspections every 60,000-90,000 miles, depending on driving conditions and the vehicle’s maintenance history.

How Valve Technology Has Evolved

Materials and Construction

Engine valve materials have transformed dramatically from the basic steel and cast iron of early engines. Modern valves incorporate advanced materials customized for extreme operating conditions. Stainless steel valves offer superior corrosion resistance and durability in standard applications. Titanium valves provide exceptional strength-to-weight ratios, making them ideal for high-performance and racing engines. Chromium and nickel alloys enhance heat resistance and longevity in valves exposed to the most demanding conditions.

Design Improvements

Valve design has progressed significantly to meet increasing performance demands. Hollow stem valves reduce overall weight while improving heat dissipation, allowing engines to operate more efficiently at higher RPMs. Advanced coatings and surface treatments minimize friction between valve stems and guides, extending service life and reducing wear. These design enhancements have enabled smaller, more efficient engines to produce greater power output while maintaining reliability.

Performance Enhancements

Variable Valve Timing (VVT) represents one of the most important advancements in valve technology. This innovation allows engines to adjust valve opening and closing timing based on engine speed and load conditions. Lift and duration adjustments optimize airflow characteristics across different operating scenarios, improving both low-end torque and high-end power. These sophisticated control systems have revolutionized engine performance, enabling manufacturers to balance power, efficiency, and emissions in ways previously impossible with fixed valve timing.

Emission Control

Valve technology evolution parallels the development of stricter emission standards worldwide. Modern valve systems work seamlessly with exhaust gas recirculation (EGR) systems to reduce nitrogen oxide emissions. Precise valve control facilitates more complete combustion, minimizing hydrocarbon emissions and improving fuel economy. Valve design refinements support air injection systems that further reduce harmful exhaust components. These developments have been crucial in meeting increasingly stringent environmental regulations while maintaining or improving engine performance and efficiency.

Conclusion

Engine valves serve as the heart of your vehicle’s respiratory system controlling the critical flow of air fuel and exhaust gases. Without properly functioning valves your engine simply can’t perform efficiently or reliably.

Understanding these precision components helps us appreciate the engineering marvel that powers our vehicles. From their specialized materials to their synchronized operation valves represent automotive engineering at its finest.

Regular maintenance and timely attention to valve-related symptoms can prevent costly repairs and extend your engine’s life. Whether you drive a daily commuter or a high-performance vehicle the humble engine valve deserves recognition for its crucial role in keeping us moving forward.

Frequently Asked Questions

What are engine valves and why are they important?

Engine valves are precision-engineered components located in the cylinder head that control the flow of air and fuel into the combustion chambers and the expulsion of exhaust gases. They’re crucial because they maintain proper compression, prevent leakage during combustion, and directly impact engine performance. Without properly functioning valves, an engine can experience overheating, power loss, or complete failure.

How many valves does a typical modern engine have?

Most modern engines utilize four valves per cylinder – two intake and two exhaust valves. This design optimizes airflow and enhances efficiency compared to older two-valve designs. The multiple valve configuration allows for better breathing, improved combustion, and ultimately more power and efficiency from the engine.

What materials are used to make engine valves?

Engine valves are typically made from high-grade steel alloys, titanium, or Inconel. Intake valves often use stainless steel, while exhaust valves require more heat-resistant materials like nickel-chromium alloys or titanium. Performance engines may use hollow sodium-filled valves for better heat dissipation. These materials are chosen for their ability to withstand extreme temperatures and pressures inside the combustion chamber.

How do intake and exhaust valves differ?

Intake valves control the air-fuel mixture flow into combustion chambers, operating at lower temperatures and optimized for airflow capacity. Exhaust valves remove burned gases after combustion, enduring much higher temperatures (up to 1,500°F) and requiring more heat-resistant materials. They’re often smaller than intake valves and may feature special cooling designs like sodium filling in high-performance applications.

What is the four-stroke combustion cycle?

The four-stroke combustion cycle consists of intake, compression, power, and exhaust strokes. During intake, intake valves open to allow the air-fuel mixture in. During compression, all valves close as the piston compresses the mixture. After ignition and the power stroke, exhaust valves open during the exhaust stroke to release spent gases. This cycle repeats thousands of times per minute with precisely timed valve operations.

What is Variable Valve Timing (VVT)?

Variable Valve Timing is an advanced technology that adjusts valve operation based on engine speed and load. It can alter when valves open and close and how far they open, optimizing performance across different driving conditions. VVT improves low-end torque, high-end power, fuel efficiency, and emissions control by providing the ideal valve timing for each specific operating condition.

What are signs of failing engine valves?

Signs of failing valves include unusual ticking or tapping noises, decreased engine performance, rough idle, difficulty starting, excessive exhaust smoke, and decreased fuel efficiency. You might also notice misfiring, compression loss, or increased oil consumption. These symptoms occur when valves no longer seal properly against their seats, allowing compression to leak or combustion gases to escape.

How often should valve maintenance be performed?

Valve maintenance should typically be performed every 60,000-90,000 miles, depending on the vehicle and driving conditions. Regular maintenance includes checking valve clearances, inspecting for wear, and ensuring proper sealing. Some modern engines have hydraulic lifters that automatically adjust clearances, requiring less frequent maintenance. Always follow your vehicle manufacturer’s recommended maintenance schedule.

Can I replace engine valves myself?

Valve replacement is a complex job requiring specialized tools, technical knowledge, and precision. It involves disassembling the cylinder head, removing valve train components, and ensuring exact specifications when reassembling. For most vehicle owners, this is best left to qualified mechanics. Improper valve installation can cause serious engine damage, making professional service the recommended approach for valve-related issues.

How do engine valves affect emissions?

Engine valves directly impact emissions by controlling the air-fuel mixture and exhaust flow. Modern valve systems work with exhaust gas recirculation (EGR) systems to reduce nitrogen oxide emissions by recirculating portion of exhaust gases back into combustion chambers. Proper valve timing and sealing ensure complete combustion, reducing unburned hydrocarbons and carbon monoxide in exhaust gases, helping vehicles meet stringent environmental regulations.