Is your car making strange noises or struggling to perform like it used to? The culprit might be a failing serpentine belt. This crucial component powers multiple systems in your vehicle, from the alternator to the power steering, and when it starts to fail, your entire car’s performance can suffer.

We’ve seen countless drivers ignore the early warning signs of serpentine belt issues, only to find themselves stranded on the roadside. By learning to recognize these symptoms early, you’ll save yourself from costly repairs and inconvenient breakdowns. In this guide, we’ll walk you through the telltale signs that your serpentine belt needs attention before small problems become major headaches.

What Is a Serpentine Belt and Why Is It Important

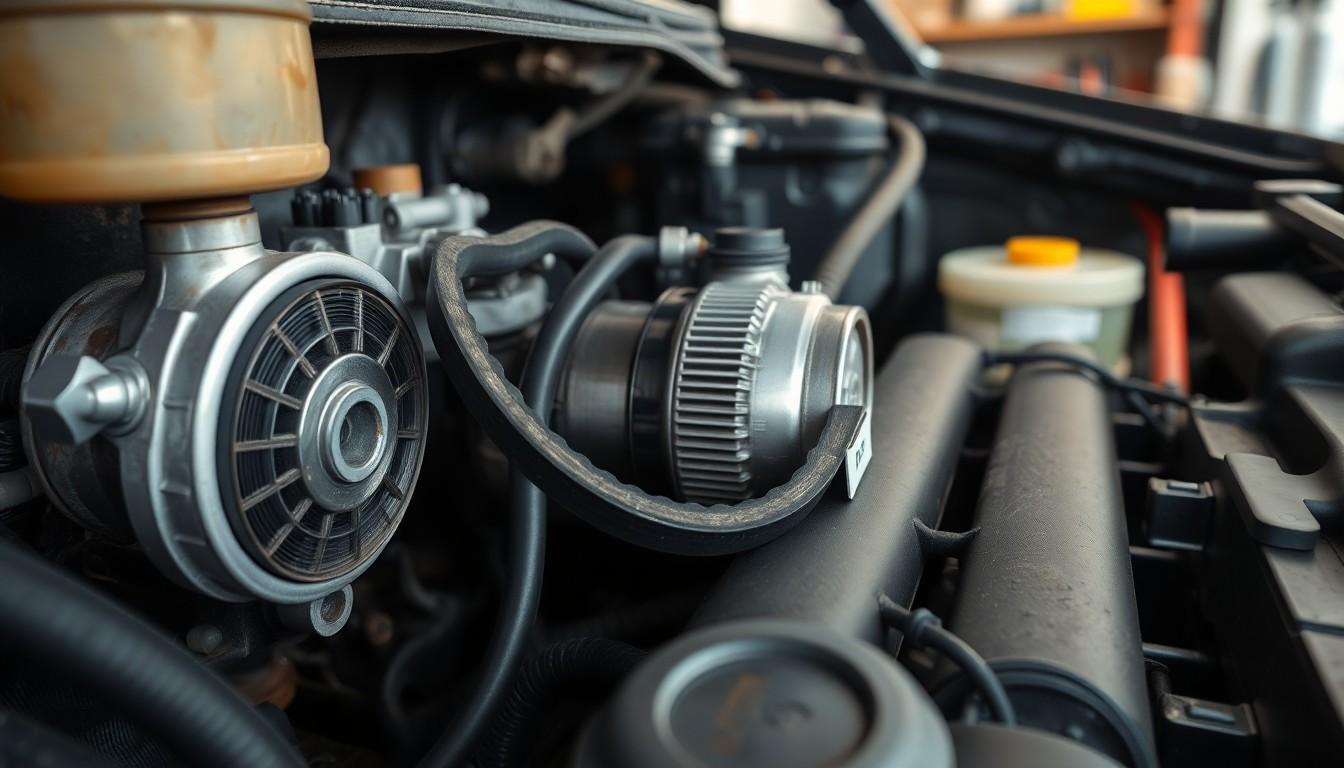

A serpentine belt serves as the primary power transmission component in modern vehicles, transferring energy from the engine’s crankshaft to multiple accessory systems. Located at the front of the engine, this single, continuous belt winds around various pulleys connected to essential components like the alternator, power steering pump, air conditioning compressor, and water pump.

Unlike older vehicles that used multiple V-belts, today’s engines employ a single serpentine belt with a flat, ribbed design that provides superior grip and efficiency. Most modern serpentine belts are constructed from EPDM (Ethylene Propylene Diene Monomer) rubber, which offers exceptional resistance to heat, cold, and common automotive fluids.

The Critical Functions of Your Serpentine Belt

The serpentine belt performs several vital functions that directly impact your vehicle’s performance and reliability:

- Powers the alternator that charges your battery and supplies electricity to all electrical components

- Drives the power steering pump that provides hydraulic pressure for smooth steering control

- Operates the air conditioning compressor to cool your vehicle’s cabin during hot weather

- Runs the water pump in many vehicles, circulating coolant through the engine to prevent overheating

Without a functioning serpentine belt, these critical systems immediately cease operation. The alternator stops charging the battery, power steering assistance fails, air conditioning shuts down, and in some vehicles, coolant circulation halts completely. This makes the serpentine belt one of the most essential components for your vehicle’s operation.

Typical Lifespan of a Serpentine Belt

Modern EPDM serpentine belts typically last between 60,000 and 100,000 miles under normal driving conditions. Environmental factors such as extreme temperatures, exposure to road debris, oil leaks, and driving habits can significantly affect this lifespan. Older vehicles with neoprene belts required replacement around 50,000 miles, but newer EPDM technology has extended this considerably.

Regular inspection of your serpentine belt during routine maintenance helps identify early signs of wear before complete failure occurs. Most manufacturers recommend checking the belt’s condition every 15,000 miles or during scheduled oil changes to ensure optimal vehicle performance and prevent unexpected breakdowns.

Common Symptoms of a Failing Serpentine Belt

Recognizing serpentine belt problems early can save you from expensive repairs and unexpected breakdowns. These symptoms typically appear gradually as the belt deteriorates over time.

Squealing or Chirping Noises

High-pitched squealing or chirping sounds from under the hood serve as an early warning sign of serpentine belt issues. These distinctive noises often become more noticeable during engine startup, acceleration, or when using accessories like air conditioning. The sounds indicate that the belt is slipping on the pulleys due to wear, improper tension, or contamination from fluids such as oil or coolant.

Visible Cracks and Wear

Physical damage to the serpentine belt appears as cracks, frayed edges, or a glazed surface (shiny, smooth appearance). A visual inspection reveals these warning signs that indicate excessive wear and deterioration. Damaged belts can’t grip the pulleys properly, reducing system efficiency and significantly increasing the risk of complete belt failure during operation.

Power Steering Problems

Stiff or unresponsive steering might indicate serpentine belt issues since the belt powers the power steering pump. Driving becomes noticeably more difficult as the belt slips or fails to properly engage the power steering components. This symptom is particularly apparent during low-speed maneuvers such as parking or handling tight turns.

Engine Overheating

Rapid engine temperature increases can occur when a failing serpentine belt impacts water pump operation. In many vehicles, the water pump relies on the serpentine belt to circulate coolant through the engine. When the belt fails, coolant circulation stops, leading to quick temperature spikes that can cause important engine damage if not addressed promptly. Additional signs include flickering lights from alternator issues, non-functioning air conditioning systems, rapid battery drain, and illuminated warning lights on your dashboard.

How Battery and Electrical Issues Signal Belt Problems

Your vehicle’s electrical system depends heavily on a functioning serpentine belt to keep the alternator powered. When the belt starts to fail, electrical components often show the first signs of trouble before mechanical problems become apparent.

Dimming Headlights and Dashboard Lights

Dimming headlights and dashboard lights are primary indicators of serpentine belt issues affecting your car’s electrical system. As your belt deteriorates, the alternator can’t efficiently charge the battery, resulting in noticeable light dimming during acceleration or when multiple electrical accessories are in use. These lighting fluctuations typically occur gradually at first, becoming more pronounced as the belt condition worsens. Drivers might notice this symptom particularly at night or in low-light conditions when headlight brightness changes are more obvious. The dashboard illumination may also fade or flicker inconsistently during normal driving, especially when electrical demands increase.

Alternator Failure Warning Signs

Alternator problems caused by a failing serpentine belt manifest through several distinct warning signs. Your dashboard battery light illuminating during driving is the most direct indicator that the alternator isn’t properly charging the system. Modern vehicles often display exact alternator warning messages on digital displays when voltage output falls below acceptable levels. Electronic systems in your car may behave erratically – power windows move slower than normal, infotainment systems restart unexpectedly, or power seats function intermittently. A battery that rapidly discharges even though being relatively new strongly suggests an alternator charging issue stemming from belt problems. Many drivers experience these symptoms progressively – starting with occasional electrical glitches that eventually lead to complete system failure when the belt breaks entirely.

Air Conditioning and Heating Malfunctions

A faulty serpentine belt directly impacts your vehicle’s air conditioning performance. When the serpentine belt deteriorates or breaks, it can no longer effectively power the A/C compressor, resulting in warm air blowing through your vents instead of cool air. This happens because the compressor requires the belt’s mechanical energy to circulate refrigerant through the A/C system.

Many drivers first notice serpentine belt problems during hot weather when their air conditioning suddenly stops working. The compressor pulley remains stationary when the belt fails, preventing the compression of refrigerant that’s essential for cooling. Even a slipping belt can cause intermittent A/C performance issues before complete failure occurs.

Heat management problems extend beyond just the air conditioning system. The serpentine belt often drives the water pump in many vehicles, which circulates coolant throughout the engine. Failure of this component leads to inadequate coolant circulation and subsequent engine overheating. Temperature gauge readings climbing into the red zone while driving may indicate a serpentine belt issue affecting your vehicle’s cooling system.

Signs that the serpentine belt is causing A/C problems include:

- No cold air coming from the vents

- Intermittent cooling performance

- Complete loss of air conditioning function

- Strange noises from the A/C compressor area

- Engine overheating occurring simultaneously

Regular inspection of your serpentine belt helps prevent unexpected air conditioning failures, especially before summer months when A/C systems face their greatest demands. Catching wear signs early protects both your comfort and your engine’s health.

How to Inspect Your Serpentine Belt

When to Inspect

Regular serpentine belt inspections prevent unexpected breakdowns and expensive repairs. Examine your belt once your vehicle reaches the 60,000-mile mark, even if it appears to be functioning normally. Most automotive experts recommend replacing the belt at approximately 90,000 miles regardless of its visible condition. Scheduling inspections during routine maintenance visits ensures you don’t overlook this critical component.

Visual Inspection

Performing a visual inspection requires your engine to be completely turned off and cool. Look carefully for cracks, splits, or fraying along the entire length of the belt. Examine the sides for glazing, which appears as a shiny, smooth surface indicating heat damage. Check for separating layers or missing chunks of grooves by gently twisting the belt. These visual indicators often appear long before performance issues develop.

Additional Checks

Testing the belt tension helps identify potential problems early. A properly tensioned belt should deflect about half an inch when pressed firmly in the middle of its longest run. Inspect for frayed edges, which indicate misalignment or contact with other engine components. Listen for unusual noises when the engine runs, as squealing often precedes visible damage. Checking the serpentine belt routing diagram (usually found under the hood) ensures the belt follows the correct path around all pulleys.

When to Replace Your Serpentine Belt

Mileage Recommendations

Most vehicle manufacturers recommend replacing the serpentine belt between 50,000 to 100,000 miles as part of regular preventative maintenance. Inspections typically begin around the 60,000-mile mark, when early signs of wear might start appearing. Even if your belt appears to be in good condition, experts suggest replacement at approximately 90,000 miles to prevent unexpected failures.

Immediate Replacement

Replace your serpentine belt immediately if you notice any of these warning signs: squealing or chirping noises from under the hood, visible cracks or fraying on the belt surface, illuminated dashboard warning lights, power steering difficulties, or air conditioning failures. Addressing these symptoms promptly prevents further damage to your vehicle’s essential systems and helps you avoid more costly repairs later.

Regular Maintenance

Regular visual inspections serve as the best defense against serpentine belt failures. Checking your belt during routine maintenance appointments allows you to identify potential issues before they escalate into major problems. These proactive inspections help detect signs of wear including cracks, glazing, or missing chunks of material that indicate the belt is deteriorating. Catching these problems early not only ensures your vehicle’s reliability but also prevents the safety risks and additional repair expenses associated with a complete belt failure.

Conclusion

Staying vigilant about your vehicle’s serpentine belt can save you from unexpected breakdowns and costly repairs. We’ve covered the critical warning signs that indicate it’s time for replacement including squealing noises performance issues and visible wear.

Remember that this small component plays an outsized role in your vehicle’s operation. By conducting regular inspections especially after 60000 miles and scheduling timely replacements you’ll protect essential systems from failure.

Don’t wait until you’re stranded with a completely failed belt. Addressing these symptoms early is one of the smartest preventative maintenance decisions you can make. Your vehicle will thank you with reliable performance and fewer emergency repair bills.

Frequently Asked Questions

What is a serpentine belt and why is it important?

A serpentine belt is a crucial power transmission component that transfers energy from the engine’s crankshaft to various accessory systems including the alternator, power steering pump, air conditioning compressor, and water pump. Without this single, continuous belt, essential vehicle systems would fail, leaving you without battery charging, power steering, air conditioning, and proper engine cooling.

How long does a serpentine belt typically last?

The typical lifespan of a serpentine belt ranges from 60,000 to 100,000 miles, depending on driving conditions and environmental factors. Most manufacturers recommend inspections starting around 60,000 miles and replacement between 50,000 to 100,000 miles, regardless of visible condition. Regular checks every 15,000 miles or during oil changes help prevent unexpected failures.

What are the common symptoms of a failing serpentine belt?

Common symptoms include high-pitched squealing or chirping noises, visible cracks and wear on the belt, power steering problems, engine overheating, flickering lights, non-functioning air conditioning, rapid battery drain, and dashboard warning lights. These warning signs should not be ignored as they can lead to complete system failure if left unaddressed.

How does a failing serpentine belt affect my vehicle’s electrical system?

A failing serpentine belt can cause dimming headlights and dashboard lights because the alternator struggles to charge the battery efficiently. Symptoms often worsen during acceleration or when multiple electrical accessories are in use. You may notice the battery warning light illuminating and erratic behavior of electronic systems, which can escalate to complete electrical failure.

Will a bad serpentine belt affect my air conditioning?

Yes, a faulty serpentine belt directly impacts air conditioning performance. When the belt deteriorates or breaks, it can no longer effectively power the A/C compressor, resulting in warm air from the vents. Signs include no cold air, intermittent cooling, complete loss of A/C function, strange noises from the compressor area, and engine overheating.

How can I inspect my vehicle’s serpentine belt?

To inspect your serpentine belt, look for cracks, splits, and glazing on the belt surface. Check for fraying edges and missing chunks of rubber. Test belt tension (it shouldn’t deflect more than ½ inch) and listen for unusual noises during operation. Use a flashlight to examine all sides of the belt and consult your vehicle’s serpentine belt routing diagram to ensure proper installation.

When should I replace my serpentine belt?

Replace your serpentine belt between 50,000 to 100,000 miles, with proactive replacement around 90,000 miles even if it looks fine. Replace immediately if you notice squealing noises, visible damage, dashboard warning lights, or any performance issues like power steering problems or overheating. Regular inspections during maintenance appointments are your best defense against unexpected failures.

Can I drive with a damaged serpentine belt?

No, driving with a damaged serpentine belt is extremely risky. If the belt breaks completely, you’ll lose power steering, alternator function, and engine cooling simultaneously, which can lead to dangerous driving conditions, stranded situations, and extensive engine damage due to overheating. Always address serpentine belt issues promptly to avoid safety hazards.