Ever wondered what keeps your engine running smoothly? The cylinder head is one of the most crucial components in your vehicle’s engine, yet many drivers don’t understand its importance. This powerhouse part serves as the “lid” for your engine cylinders and houses essential components like valves, springs, and fuel injectors.

We’ve seen countless engine problems that trace back to cylinder head issues. When functioning properly, this component manages airflow, fuel delivery, and exhaust—essentially controlling your engine’s breathing process. Without a well-maintained cylinder head, you’ll face decreased performance, poor fuel economy, or even complete engine failure.

What Is a Cylinder Head: An Essential Engine Component

A cylinder head forms the upper section of an internal combustion engine, sealing the top of the cylinders and creating a space for combustion to occur. Positioned above the engine block, this critical component houses several vital engine parts including valves, valve springs, camshafts, and spark plugs. Its primary function involves controlling the flow of air and fuel into the cylinders while directing exhaust gases away from the combustion chamber.

Modern cylinder heads are typically made from aluminum alloy or cast iron, with aluminum being preferred in most contemporary vehicles due to its lighter weight and superior heat dissipation properties. Cast iron heads, though heavier, offer exceptional durability and heat resistance, making them suitable for certain high-performance applications.

The design of a cylinder head significantly impacts an engine’s performance characteristics, efficiency, and emissions output. Manufacturers engineer cylinder heads with exact port shapes, combustion chamber designs, and valve arrangements to optimize airflow and combustion efficiency for their intended application. Performance enthusiasts often modify cylinder heads to increase power output by improving these flow characteristics and allowing engines to breathe more effectively.

The Function and Purpose of Cylinder Heads

The cylinder head serves as a critical engine component with multiple essential functions beyond just sealing the combustion chamber. It’s designed to handle intense pressure and temperatures while ensuring proper air and fuel flow through the engine system.

How Cylinder Heads Seal the Combustion Chamber

Cylinder heads create an airtight seal at the top of the combustion chamber through several key mechanisms. They form a physical barrier that contains the explosive force of combustion within the cylinder. A head gasket sits between the cylinder head and engine block, preventing leaks of water, oil, and combustion gases that could compromise engine performance. This gasket plays a crucial role in maintaining the proper compression ratios needed for efficient engine operation. Proper torquing of cylinder head bolts ensures even pressure distribution across the sealing surface, maintaining the integrity of this critical seal under varying engine temperatures and pressures.

Managing Airflow and Exhaust

Cylinder heads control the precise flow of air, fuel, and exhaust gases that determine engine efficiency and power. They house intake ports that direct the air-fuel mixture into the combustion chamber at exact angles and velocities for optimal combustion. The exhaust ports channel hot gases away from the cylinders after combustion has occurred. Valves embedded in the cylinder head open and close with precise timing to regulate these flows, with intake valves allowing the air-fuel mixture in and exhaust valves releasing spent gases. Many performance enthusiasts modify these port shapes and sizes to increase airflow capacity and improve engine breathing. The cylinder head’s internal passages also circulate coolant to dissipate heat, preventing component damage from the extreme temperatures generated during combustion.

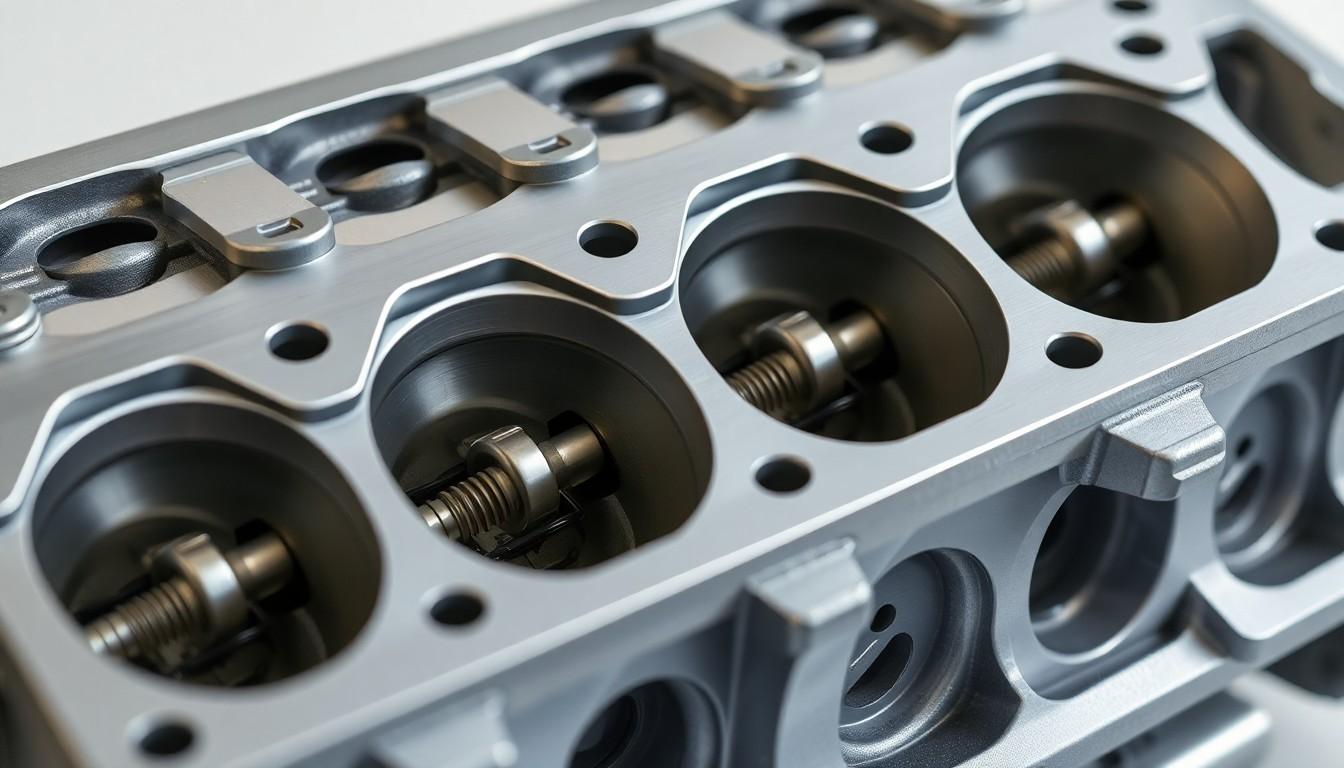

Anatomy of a Cylinder Head

The cylinder head features a complex internal structure that’s critical to engine operation. This intricate casting, typically made from aluminum alloy or cast iron, contains multiple precision-engineered components working together to control combustion and engine efficiency.

Valves, Ports, and Passages

Valves serve as the gatekeepers for air, fuel, and exhaust flow within the cylinder head. Intake valves open to allow the air-fuel mixture into the combustion chamber, while exhaust valves release spent gases after combustion occurs. These components are precisely machined to open and close at exact moments during the engine’s operating cycle, coordinating with piston movement. The ports connect to these valves, forming channels through which gases travel—intake ports direct the air-fuel mixture toward the combustion chamber, and exhaust ports guide waste gases away from the engine. Smooth, properly shaped passages enhance engine efficiency by minimizing resistance to airflow, with performance engines often featuring polished or ported passages to maximize horsepower.

Combustion Chambers

Combustion chambers form the critical space where the controlled explosion of fuel occurs within an engine. The cylinder head creates the upper boundary of this chamber, with its design significantly influencing compression ratios, flame propagation, and overall engine efficiency. Different chamber shapes—hemispheric, pentroof, wedge—each provide distinct performance characteristics and combustion properties. Modern combustion chamber designs focus on optimizing fuel burn patterns to increase power output while reducing emissions. The chamber’s volume directly affects the engine’s compression ratio, with higher compression generally yielding more power but requiring higher octane fuel to prevent detonation.

Valve Train Components

Valve train components housed within the cylinder head control the precise timing of valve operations. These include valve springs that provide tension to close valves, valve guides that maintain proper valve alignment, and valve seats that create sealing surfaces when valves close. Many engines incorporate camshafts directly in the cylinder head for overhead cam designs, allowing more direct actuation of valves. Rocker arms or followers translate camshaft motion into valve movement, with different designs offering varying degrees of mechanical advantage and control precision. The valve train must maintain tight tolerances and proper lubrication to function reliably at thousands of cycles per minute, with high-performance engines often using specialized materials like titanium valves or ceramic valve seats to withstand extreme operating conditions.

Types of Cylinder Heads

Cylinder heads come in various configurations based on engine design and applications. These different types significantly impact engine performance, efficiency, and maintenance requirements.

Cast Iron vs. Aluminum Heads

Cast iron and aluminum represent the two primary materials used in cylinder head manufacturing, each offering distinct advantages. Cast iron heads were traditionally preferred for their exceptional durability, strength, and heat resistance capabilities, making them ideal for high-compression engines. Aluminum heads have become the standard in modern vehicles due to their superior weight reduction properties, typically weighing 50% less than comparable cast iron versions. The improved thermal conductivity of aluminum heads allows engines to cool more efficiently, reducing the risk of overheating and warping during extended operation. Cost considerations also influence material selection, with cast iron generally being less expensive to manufacture but potentially increasing overall vehicle operating costs due to added weight and reduced fuel efficiency.

OHV vs. OHC Designs

Overhead Valve (OHV) and Overhead Camshaft (OHC) designs represent fundamentally different approaches to valve actuation in engines. OHV engines position the camshaft within the engine block, operating valves through a system of lifters, pushrods, and rocker arms to transfer motion from the camshaft to the valves. This compact design creates a lower overall engine height and simpler maintenance for basic adjustments. OHC engines locate the camshaft directly above the valves within the cylinder head itself, eliminating pushrods and allowing for more precise valve control. Single Overhead Camshaft (SOHC) systems use one camshaft to operate both intake and exhaust valves, offering a balance between performance and complexity. Dual Overhead Camshaft (DOHC) configurations employ separate camshafts for intake and exhaust valves, enabling optimized valve timing and lift profiles for each function. High-performance applications typically favor DOHC designs for their ability to achieve higher RPM limits and better breathing efficiency at elevated engine speeds.

Common Cylinder Head Problems

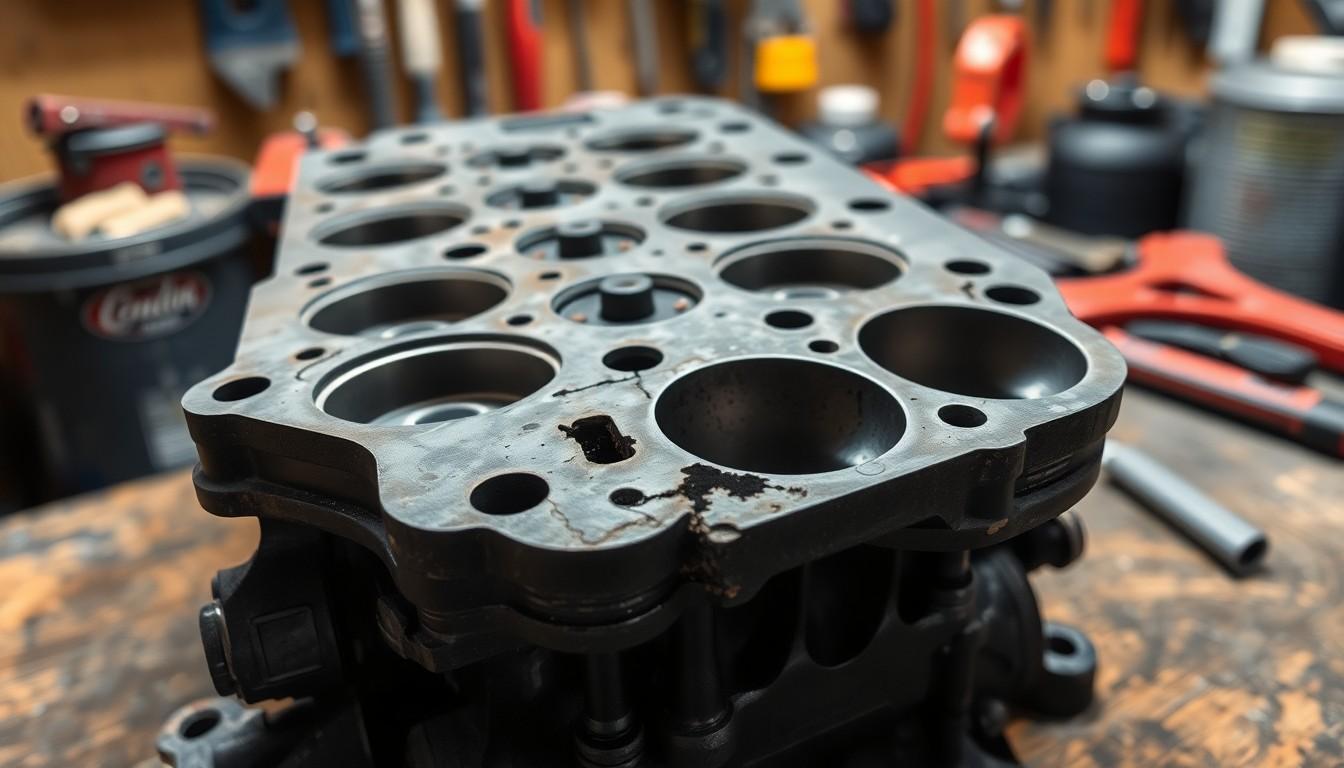

Cylinder head problems can significantly impact engine performance and longevity. These issues often develop gradually but can lead to catastrophic engine failure if left unaddressed.

Warping and Cracking Issues

Cylinder heads frequently suffer from warping or cracking due to excessive heat exposure. Overheating causes the metal to expand and contract unevenly, compromising the head’s ability to properly seal the combustion chamber. This uneven expansion creates structural weaknesses that manifest as visible cracks or subtle warping that’s difficult to detect without precision measurement tools. Mechanical stress, manufacturing defects, and improper installation techniques also contribute to crack formation in cylinder heads. Addressing these issues typically requires professional resurfacing of the cylinder head or complete replacement in severe cases.

Valve and Seal Failures

Valve failures represent one of the most common cylinder head complications that drastically reduce engine efficiency. Intake and exhaust valves deteriorate from continuous exposure to heat, pressure, and friction, resulting in poor seating, burning, or complete breakage. These valve issues directly translate to power loss, increased fuel consumption, and rough engine operation. Head gasket failures occur when this critical seal between the cylinder head and engine block breaks down, allowing coolant and oil to mix or enter the combustion chamber. The consequences of seal failures include white exhaust smoke, overheating, loss of compression, and potential hydrolocking that can destroy an engine. Early detection of valve and seal problems through monitoring engine performance changes can prevent extensive damage and costly repairs.

Maintaining Your Cylinder Head

Proper cylinder head maintenance is essential for preserving engine performance and preventing costly repairs. Regular care helps extend the lifespan of this critical component and maintains optimal engine function.

Regular Inspection Tips

Regular inspections of your cylinder head can catch problems before they become serious. Check for coolant or oil leaks around the head gasket, as these indicate potential seal failures. Monitor your cooling system’s performance regularly, since overheating is a primary cause of cylinder head damage. Consistent oil changes are crucial for maintaining proper lubrication of valve train components housed in the cylinder head. Periodic valve adjustments ensure correct operation and prevent performance issues related to improper valve seating or timing. These simple inspection habits can significantly extend your cylinder head’s life and maintain engine efficiency.

When to Replace vs. Repair

Replacement

Complete replacement becomes necessary when your cylinder head shows cracks or severe structural damage. These defects typically lead to coolant or oil leaks that can cause catastrophic engine failure if left unaddressed. Important wear on the cylinder head surface or extensive damage to the head gasket also generally requires replacement rather than repair. Replacement provides a fresh start with proper tolerances and sealing surfaces, eliminating the risk of recurring problems from compromised components.

Repair

Minor issues often don’t require full replacement. Small leaks around the head gasket can be fixed by replacing just the gasket or resurfacing the cylinder head to restore a proper seal. Valve-related problems frequently respond well to repairs such as valve replacement, seat grinding, or adjustment rather than replacing the entire head assembly. Surface imperfections can be corrected through professional machining or resurfacing, restoring the cylinder head to proper specifications. Remember that proper torquing of cylinder head bolts is essential during reassembly to prevent future leaks and ensure even pressure distribution across the gasket.

Professional inspection is recommended whenever you’re uncertain about cylinder head condition. Experienced mechanics can accurately assess damage and provide appropriate repair options, potentially saving you from unnecessary expenses or overlooking serious issues that could lead to engine failure.

Conclusion

The cylinder head stands as one of the most critical components in your vehicle’s engine. This precision-engineered part manages airflow controls combustion and helps maintain optimal engine temperatures. With its complex network of valves ports and cooling passages it’s truly the command center of your engine’s operation.

Remember that proper maintenance of your cylinder head isn’t optional—it’s essential for your engine’s performance and longevity. By understanding this vital component you’ll make better decisions about your vehicle’s care whether you’re performing routine maintenance troubleshooting problems or considering performance upgrades.

Taking care of your cylinder head means taking care of your entire engine and that translates to a smoother more reliable driving experience for years to come.

Frequently Asked Questions

What is a cylinder head and why is it important?

A cylinder head is a critical engine component that seals the top of the cylinders, creating a combustion chamber. It houses valves, springs, fuel injectors, and spark plugs while managing airflow, fuel delivery, and exhaust. Its importance cannot be overstated as it directly impacts engine performance, efficiency, and emissions. A malfunctioning cylinder head can lead to decreased power, poor fuel economy, or complete engine failure.

What materials are cylinder heads made from?

Cylinder heads are typically made from either aluminum alloy or cast iron. Aluminum is favored in modern engines for its lighter weight and superior heat dissipation properties, which improve overall performance and fuel efficiency. Cast iron heads, while heavier, are known for their durability and strength, making them suitable for certain high-stress applications and older engine designs.

What are the main functions of a cylinder head?

The cylinder head creates an airtight seal for the combustion chamber, controls the precise flow of air and fuel into the cylinders, directs exhaust gases away from the engine, and circulates coolant through internal passages to manage heat. It also houses the valve train components that control the timing of intake and exhaust operations, which is crucial for efficient combustion and engine performance.

How does the cylinder head design affect engine performance?

Cylinder head design significantly impacts engine performance through its port shapes, combustion chamber design, and valve arrangement. These elements determine airflow efficiency, combustion characteristics, and heat management. Performance enthusiasts often modify cylinder heads to enhance these aspects, resulting in increased power output. Manufacturers optimize designs to balance performance, efficiency, emissions, and reliability according to the engine’s intended application.

What’s the difference between OHV and OHC cylinder heads?

Overhead Valve (OHV) designs position the camshaft in the engine block with pushrods activating the valves, creating a compact engine but with more moving parts. Overhead Camshaft (OHC) designs place the camshaft directly above the valves in the cylinder head, reducing moving parts and allowing higher RPM operation. OHC designs are further categorized as Single (SOHC) or Dual (DOHC), with DOHC offering optimized valve control for performance applications.

What are common cylinder head problems?

Common cylinder head problems include warping and cracking from overheating, valve and seal failures causing compression loss, carbon buildup restricting airflow, and head gasket failures leading to coolant or oil leaks. These issues typically manifest as decreased engine performance, unusual noises, overheating, excessive oil consumption, or visible leaks. Early detection is crucial to prevent more extensive engine damage.

How can I maintain my engine’s cylinder head?

Maintain your cylinder head by monitoring the cooling system (checking coolant levels and thermostat function), ensuring timely oil changes with the correct oil type, avoiding engine overheating, addressing strange noises promptly, and following manufacturer-recommended service intervals. Regular inspection for oil or coolant leaks around the head gasket area can help identify potential problems before they cause significant damage.

When should a cylinder head be replaced versus repaired?

Replace a cylinder head when it has severe cracking, extensive warping, or irreparable damage to critical surfaces or components. Consider repair for minor issues like small cracks, worn valve guides, or surface imperfections that can be machined. The decision often depends on the extent of damage, availability of replacement parts, and cost comparison. Professional inspection is recommended to accurately assess the cylinder head’s condition.