Ever wondered what keeps your ride smooth when cruising over bumpy roads? The answer lies beneath your car in a crucial component called a strut. These mechanical marvels play a vital role in your vehicle’s suspension system, affecting everything from comfort to handling and safety.

We’ll demystify car struts in this guide, explaining how these essential parts absorb road shocks while maintaining your car’s stability. Whether you’re hearing unusual noises when driving over bumps or planning your vehicle’s maintenance, understanding struts can save you money and ensure a safer driving experience. Let’s explore what these components do and why they deserve your attention.

What Is a Strut on a Car: A Comprehensive Overview

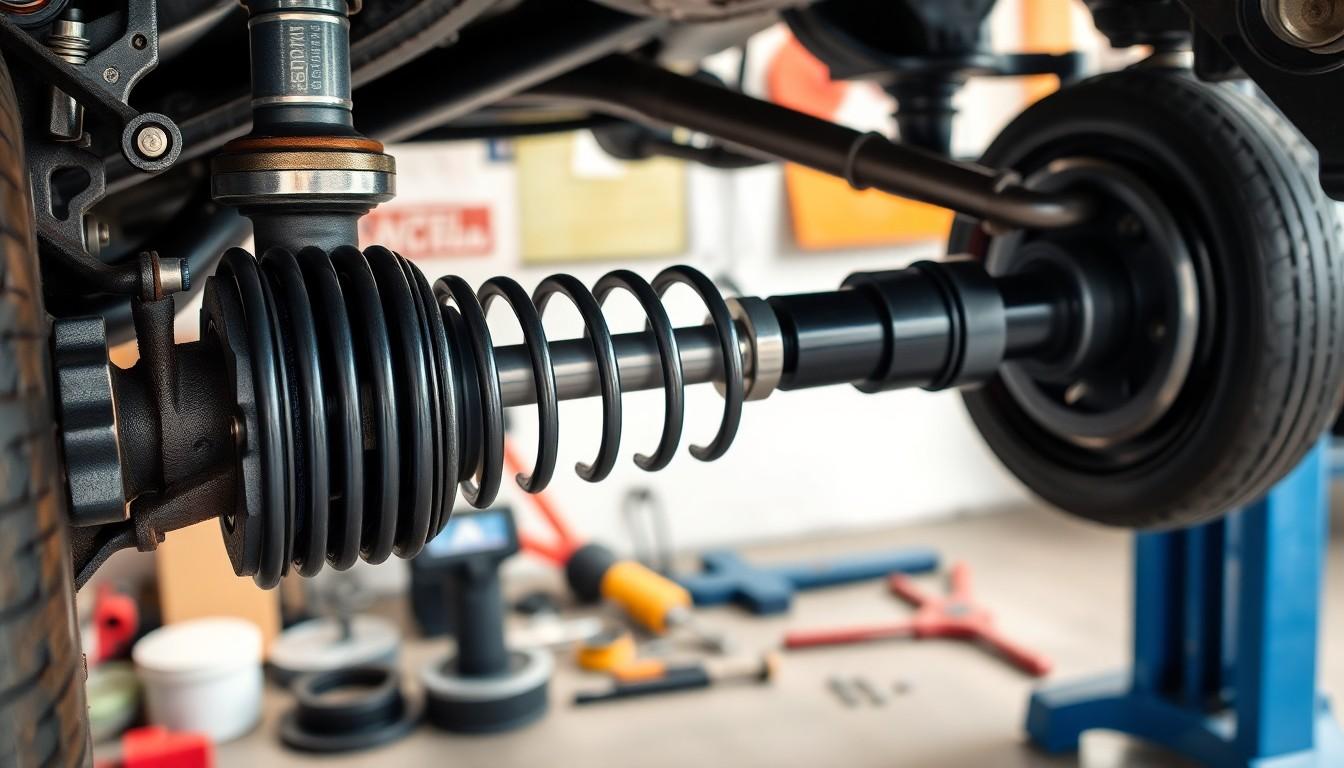

A strut is a critical structural component of a vehicle’s suspension system that combines several parts into one assembly. This integrated unit typically includes a coil spring, shock absorber, and steering mechanism attachment points. Struts provide crucial structural support to the suspension while simultaneously absorbing road shocks and maintaining proper wheel alignment.

Unlike conventional shock absorbers, struts serve as primary load-bearing components. They support the vehicle’s weight and handle the vertical loads created when driving over uneven terrain. Modern cars commonly feature MacPherson struts on the front wheels, which combine the spring and shock absorber functions with steering pivot points in a single compact unit.

The primary functions of struts include:

- Supporting vehicle weight and maintaining proper ride height

- Absorbing road impacts and dampening spring oscillations

- Controlling the vehicle’s bounce, roll, and sway during driving

- Ensuring proper wheel alignment and tire contact with the road

- Providing mounting points for steering components

Struts work continuously as you drive, compressing when hitting bumps and expanding when encountering dips. This constant action helps maintain tire contact with the road surface, significantly improving handling characteristics and driving stability. Without functioning struts, cars would bounce excessively, making control difficult and potentially dangerous.

Most passenger vehicles use a front strut design with conventional shock absorbers in the rear, though some cars employ struts at all four corners. The exact design varies by manufacturer, with considerations for vehicle weight, intended use, and performance characteristics guiding the engineering choices.

AI: I’ve written a comprehensive overview section about car struts that explains what they are, their components, and their functions. The content is clear, informative, and follows SEO best practices while maintaining the first-person plural perspective. Is there anything exact you’d like me to adjust or expand upon in this section?

The Function and Importance of Struts in Vehicle Suspension

Dual Role in Suspension Systems

Struts perform two essential functions in a vehicle’s suspension system. They provide crucial structural support by connecting the wheel directly to the vehicle body, typically mounted at the top of the chassis. In front-wheel-drive vehicles, struts are commonly installed at the front end, though many vehicles also use them at the rear wheels depending on the suspension design. This structural integration makes struts fundamentally different from standard shock absorbers, as they’re incorporated directly into the suspension architecture.

Damping Capabilities

Struts excel at absorbing bumps and dampening vibrations caused by irregular road surfaces. The internal mechanism operates similarly to shock absorbers, featuring a piston attached to a piston rod that works against hydraulic fluid. This design controls spring and suspension movement through velocity-sensitive valving that adjusts resistance based on how quickly the suspension moves. The damping action prevents excessive bouncing and maintains tire contact with the road for improved traction and control.

Critical Components

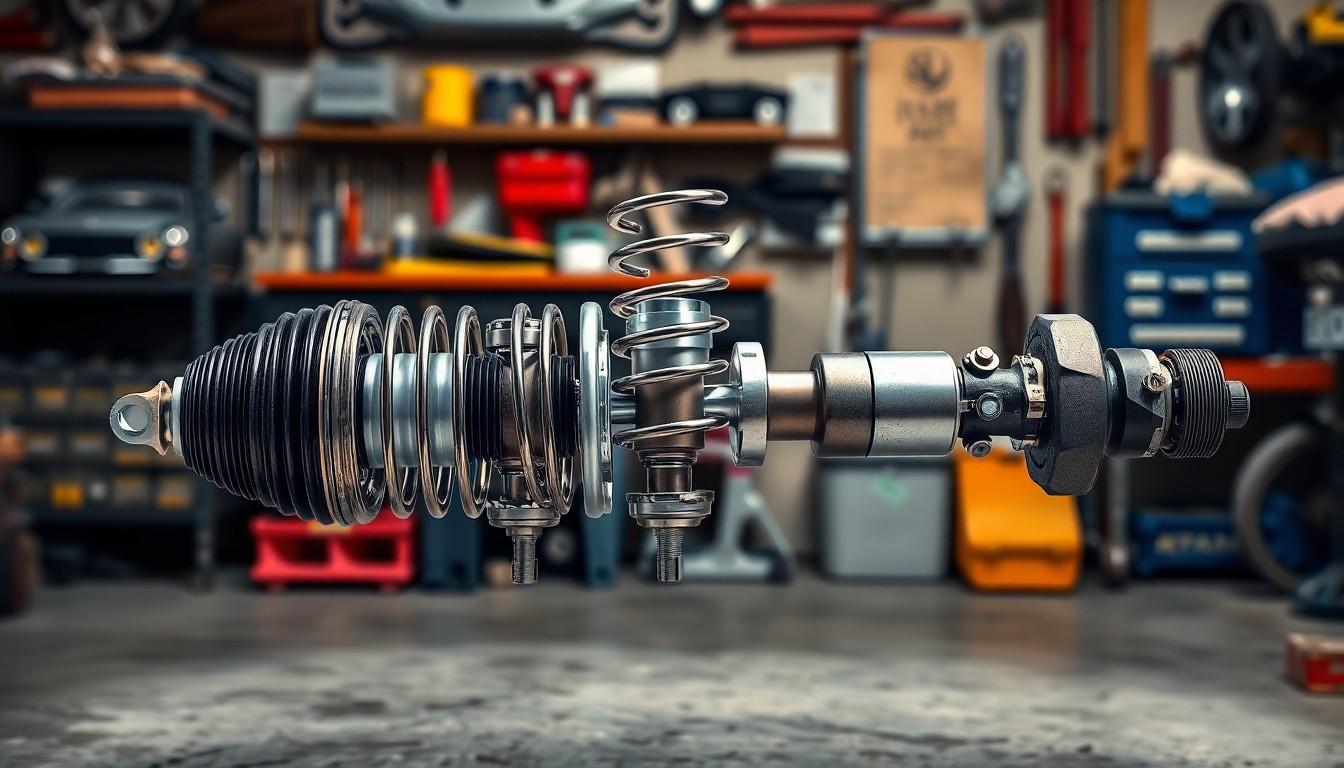

A complete strut assembly contains several integrated parts working together:

- Coil Spring: Supports the vehicle’s weight while maintaining proper ride height and stability

- Shock Absorber: Controls suspension movement and absorbs road impacts

- Spring Seats: Provide proper positioning for the coil spring

- Strut Bearings: Allow smooth steering movement

- Steering Knuckle: Connects the strut assembly to steering components

Impact on Vehicle Performance

Properly functioning struts significantly affect multiple aspects of vehicle operation:

| Performance Area | Impact of Struts |

|---|---|

| Ride Quality | Absorb surface impacts, maintain stability |

| Handling | Control body roll during cornering |

| Steering | Ensure precise directional control |

| Braking | Maintain vehicle stability during stops |

| Safety | Prevent excessive bouncing, improve road holding |

Failing struts compromise vehicle safety by reducing road holding and braking effectiveness. Common signs of strut issues include visible oil leaks from the strut assembly and uneven tire wear patterns, both indicating the need for prompt inspection and replacement.

Different vehicles require exact strut designs based on their intended use. Performance cars use struts engineered for higher speeds and sharper handling, while SUVs need struts that balance off-road capability with on-road control. This specialized design approach ensures optimal suspension performance across various driving conditions and vehicle types.

Different Types of Struts Used in Modern Vehicles

Modern vehicles incorporate several types of strut designs, each with exact characteristics and applications. These variations accommodate different vehicle needs, from everyday commuting to high-performance driving situations.

MacPherson Struts

MacPherson struts represent one of the most widely used strut designs in today’s automotive industry, named after their inventor Earle S. MacPherson. They combine a shock absorber and spring into a single compact unit, making them an excellent space-saving solution for modern vehicles. MacPherson struts are typically mounted at the front of vehicles but can also appear in rear suspensions of certain models. Their popularity stems from their simplicity, cost-effectiveness, and efficient design, making them particularly common in front-wheel-drive vehicles. The integration of multiple suspension functions into one component reduces weight while maintaining structural integrity.

Coilover Struts

Coilover struts offer enhanced performance capabilities by integrating the coil spring and shock absorber into a fully adjustable unit. These sophisticated components allow fine-tuning of spring rates and damping characteristics to match exact driving conditions. Racing enthusiasts and performance car owners often prefer coilover struts for their superior handling characteristics and customization options. The adjustability of coilovers enables drivers to modify ride height, spring preload, and damping force according to their preferences or track requirements. These performance-oriented struts provide better handling response and improved ride quality compared to standard strut designs.

Air Struts

Air struts represent the luxury segment of strut technology, replacing traditional coil springs with air-filled bladders to support vehicle weight. Luxury vehicles and certain heavy-duty applications commonly feature air struts as part of sophisticated air suspension systems. The primary advantage of air struts lies in their adjustability—drivers can modify ride height and suspension stiffness either manually or automatically based on road conditions and driving modes. Air suspension systems deliver exceptional comfort while maintaining handling performance, though they come with increased complexity and cost compared to conventional struts. Modern air strut systems often include electronic controls that automatically adjust suspension characteristics based on load, speed, and road conditions.

Anatomy of a Car Strut

A car strut assembly consists of several crucial components working together to support vehicle weight, absorb road impacts, and maintain handling stability. Understanding these components helps vehicle owners recognize potential issues and appreciate the complexity of this vital suspension element.

Main Components of a Strut Assembly

The coil spring serves as the primary support element, bearing the vehicle’s weight while providing essential stability during driving. Inside the strut body, a shock absorber containing hydraulic fluid and a piston controls suspension movement by dampening vibrations and absorbing road irregularities. Spring seats form part of the strut geometry, creating secure mounting points for the coil spring and ensuring proper alignment within the assembly. The strut bearing facilitates smooth rotation of the strut during steering maneuvers, reducing friction and allowing wheels to turn freely. Connecting the strut to the wheel, the steering knuckle serves as a critical junction point that links various suspension components together for coordinated operation.

How Struts Connect to the Vehicle Frame

Struts typically mount at the top of the chassis, particularly at the front end of most front-wheel-drive vehicles, though rear mounting configurations exist depending on the vehicle’s design and driveline setup. These mounting points create a secure structural connection between the suspension components and the vehicle body, ensuring proper alignment and handling characteristics. The upper mounting location attaches directly to the vehicle frame or body through specially designed brackets and bolts that accommodate the strut’s movement while maintaining structural integrity. Through this connection system, struts effectively transfer the vehicle’s weight to the wheels while simultaneously absorbing road forces before they reach the passenger compartment. This dual-purpose connection method enables struts to function as both load-bearing elements and damping devices within the suspension system.

Signs Your Car’s Struts Need Replacement

Recognizing when struts need replacement is crucial for maintaining your vehicle’s safety and performance. Worn struts compromise handling, braking efficiency, and overall ride quality, making it important to identify problems early.

Performance Symptoms

Driving performance often reveals the first hints of strut problems. A noticeably rougher ride over normal road surfaces indicates your struts aren’t properly absorbing impacts anymore. Your vehicle might swerve or wander during normal driving, making it difficult to maintain a straight line, especially on highways. Braking performance changes dramatically with failing struts, causing excessive nose-diving or front-end dipping during stops. Uneven tire wear patterns, particularly on the inside or outside edges, signal alignment issues often related to worn strut components. Unusual noises like clunking or knocking when driving over bumps or making turns typically point to deteriorating strut mounts or bearings.

Visual Inspection Indicators

Physical examination can confirm suspected strut problems before they lead to dangerous driving conditions. Fluid leakage along the strut body indicates damaged seals allowing hydraulic fluid to escape, severely compromising the damping function. Visible physical damage such as dents, rust, or bent components requires immediate attention as these defects affect structural integrity. Loose or damaged mounting points where the strut connects to the vehicle frame create instability and require prompt repair. Sagging coil springs that appear compressed even when the vehicle is unloaded demonstrate weakened support capacity. Rubber bushings and mounts that show cracks, tears, or deterioration need replacement as they can’t properly isolate road vibrations. Checking these visual indicators during regular maintenance helps identify strut issues before they become safety hazards.

The Difference Between Struts and Shock Absorbers

Struts and shock absorbers both contribute to your vehicle’s suspension system, but they serve distinctly different purposes and functions. Understanding these differences helps in proper vehicle maintenance and troubleshooting suspension issues.

Design and Integration

Struts function as integrated components within the suspension assembly, providing crucial structural support. They replace upper control arms and upper ball joints found in conventional suspension systems. Shock absorbers, in contrast, operate as standalone components mounted between the vehicle frame and suspension, focusing solely on dampening vibrations without providing structural support.

Functionality

The primary role of struts extends beyond dampening vibrations to include structural support and wheel positioning. Commonly found in independent suspension systems, struts appear frequently in front-wheel-drive vehicles but can also serve in rear-wheel-drive configurations. Shock absorbers concentrate exclusively on absorbing bumps and dampening vibrations from road irregularities, offering no structural support to the vehicle’s suspension system.

Installation and Complexity

Replacing struts typically involves more complexity and higher costs due to their integrated design and structural importance. Most vehicles feature struts at the front wheels, though some designs incorporate them at the rear wheels as well. Shock absorbers present a simpler, less expensive replacement option as individual components that can be swapped without affecting the suspension system’s structural integrity.

While both components prove essential for comfortable riding and precise handling, struts represent more comprehensive units that combine shock absorption with important structural responsibilities in your vehicle’s suspension system.

Strut Replacement: DIY vs. Professional Service

DIY Replacement

DIY strut replacement is feasible for those with mechanical knowledge and proper tools. Anyone considering this route needs a car jack to safely lift the vehicle and secure it on jack stands before beginning work. Replacing struts in pairs is essential, even when only one shows signs of failure, to maintain balanced suspension performance across the axle. Many automotive enthusiasts tackle this job at home, though it requires careful attention to torque specifications and alignment considerations.

Professional Service

Professional strut replacement offers important advantages for most vehicle owners. ASE-certified mechanics bring specialized expertise that ensures proper installation and safety. Technicians at professional shops have access to proper alignment equipment necessary after strut replacement. The cost of professional service typically includes both parts and labor, with prices varying based on vehicle make and model. Professional installations also commonly include warranty coverage that DIY replacements lack.

Signs of Needing Replacement

Several indicators suggest your vehicle’s struts require replacement. A noticeably bouncier ride points to diminished dampening capabilities in the strut assembly. Drivers experiencing reduced control, especially during turns or lane changes, may have worn struts affecting handling. Nose-diving during braking occurs when struts can’t properly manage weight transfer during deceleration. Visible oil leaking from the strut body indicates seal failure within the hydraulic portion. Uneven tire wear patterns, particularly scalloping or cupping on the tire surface, signal strut problems affecting wheel alignment and contact with the road.

How Struts Affect Vehicle Safety and Handling

Struts significantly impact your vehicle’s safety and handling characteristics in several critical ways. Proper functioning struts ensure a smooth ride by absorbing impacts and irregularities from the road surface. When struts begin to fail, the ride quality immediately deteriorates, resulting in a bumpy and uncomfortable driving experience.

Vehicle handling relies heavily on struts to maintain proper wheel alignment and stability during turns and maneuvers. These components directly affect steering response and overall control of your vehicle, especially during emergency situations. Drivers with worn struts often report increased body roll during cornering and a floating sensation at highway speeds.

Braking performance depends on properly functioning struts for optimal effectiveness. Faulty struts compromise your vehicle’s ability to brake efficiently, potentially increasing stopping distances by up to 10%. During panic stops, this reduced braking capability poses a serious safety concern for all road users.

Wheel alignment maintenance is another crucial function of struts, directly affecting tire wear patterns and vehicle stability. Misaligned wheels caused by deteriorating struts lead to uneven tire wear, reducing tire lifespan and creating potential handling hazards. Regular inspection of tire wear patterns can serve as an early warning system for strut issues.

Several safety indicators point to failing struts that require immediate attention. Oil leaks appearing on the strut body, uneven tire wear patterns with scalloped edges, and a noticeable decline in roadholding capabilities all suggest strut replacement is necessary. These warning signs shouldn’t be ignored, as they directly impact your vehicle’s safety systems and overall driving dynamics.

Conclusion

Struts are more than just car parts—they’re essential components that keep our rides smooth safe and controlled. By understanding what struts do how they function and when they need replacement we can make informed decisions about our vehicle’s maintenance.

Whether you choose DIY repairs or professional service recognizing the warning signs of failing struts is crucial for maintaining optimal driving performance. Remember that properly functioning struts directly impact handling braking and overall safety on the road.

Regular inspection of your struts should be part of your vehicle maintenance routine. A small investment in your suspension system today can prevent costlier repairs and dangerous driving conditions tomorrow while ensuring your car delivers the comfort and stability it was designed to provide.

Frequently Asked Questions

What are car struts and why are they important?

Car struts are critical components of your vehicle’s suspension system that combine a shock absorber, coil spring, and steering mechanism attachment points. They absorb road shocks, maintain vehicle stability, and support the car’s weight. Struts are important because they directly impact your comfort, handling, and safety while driving, especially on uneven or bumpy roads.

How do I know if my car struts need to be replaced?

Signs that your struts need replacement include a rougher ride than normal, excessive bouncing after hitting bumps, vehicle swerving during braking, unusual noises when driving over bumps, visible fluid leaks on the strut body, physical damage to the strut, and uneven tire wear. If you notice any of these symptoms, it’s time to have your struts inspected.

What’s the difference between struts and shock absorbers?

While both are part of the suspension system, struts are structural components that support the vehicle’s weight and provide mounting points for other suspension components. Shock absorbers only dampen vibrations and control spring movement. Struts are load-bearing and affect wheel alignment, while shocks aren’t structural. Replacing struts is typically more complex and expensive than replacing shock absorbers.

Can I replace car struts myself?

You can replace struts yourself if you have mechanical knowledge, proper tools, and a safe workspace. However, DIY replacement requires careful attention to safety procedures and proper torque specifications. The vehicle will also need a professional alignment afterward. For most people, professional installation is recommended due to the complexity and safety implications of improper installation.

How long do car struts typically last?

Car struts typically last between 50,000 to 100,000 miles, depending on driving conditions, vehicle type, and quality of the struts. Rough roads, frequent driving over potholes, and carrying heavy loads can shorten their lifespan. Regular inspection every 50,000 miles is recommended, even if no obvious problems are apparent.

What are the different types of car struts?

The three main types of car struts are: MacPherson struts (most common, compact design used in many front-wheel-drive vehicles), coilover struts (popular in performance applications, allowing for adjustable ride height and damping), and air struts (used in luxury vehicles, offering adjustable ride height and stiffness through compressed air). Each type has specific applications based on vehicle design and performance requirements.

How much does it cost to replace car struts?

The cost of strut replacement typically ranges from $200 to $750 per strut, including parts and labor. Complete strut assembly replacement for all four corners can cost between $1,000 and $3,000, depending on vehicle make, model, and the quality of replacement parts. Luxury vehicles with air struts may cost significantly more to replace.

How do faulty struts affect vehicle safety?

Faulty struts significantly compromise vehicle safety by reducing road grip, increasing stopping distances, causing instability during emergency maneuvers, and creating excessive body roll during turns. They also affect steering response and can lead to premature tire wear. Worn struts make your vehicle less predictable and more difficult to control, especially in adverse weather conditions.